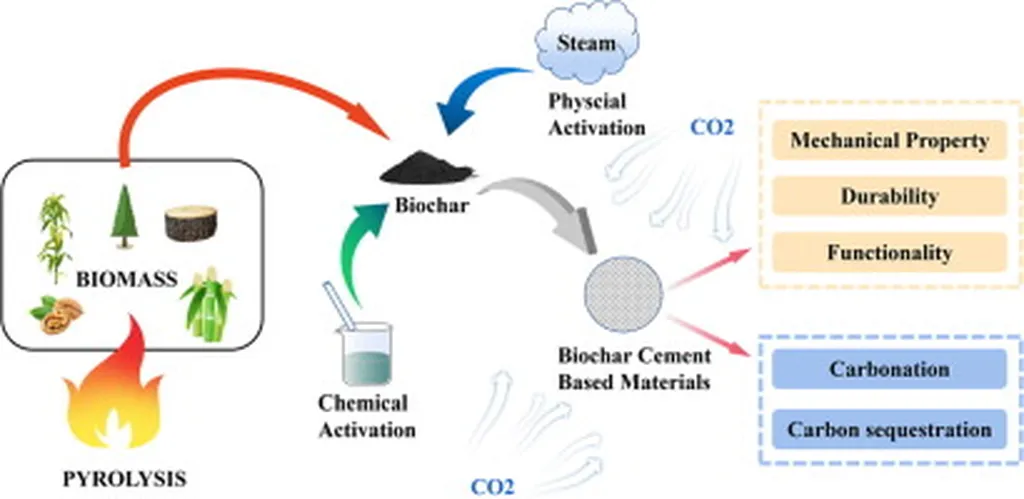

In the quest to reduce the construction industry’s substantial carbon footprint, researchers are turning to an unlikely ally: biochar. This carbon-rich material, derived from biomass through pyrolysis, is emerging as a promising supplementary cementitious material, offering a dual benefit of enhancing cement composites and capturing carbon. A recent mini-review published in the journal ‘Zdania’ (Buildings) by Shah Room of the University of West London delves into the potential of biochar to revolutionize sustainable construction.

The construction sector is a significant contributor to global greenhouse gas emissions, with cement production alone accounting for approximately 7–8% of global CO2 emissions. As the demand for sustainable construction practices grows, the search for alternative low-carbon cementitious materials has become increasingly urgent. Biochar, with its unique properties and carbon capture capabilities, has surfaced as a viable solution.

Room’s review investigates the multifaceted role of biochar in cement composites, highlighting its impact on hydration kinetics, microstructural development, and fresh-state properties. “Biochar not only enhances the mechanical performance of cement composites but also facilitates carbon capture, making it a dual-function material,” Room explains. This dual functionality is a game-changer, as it addresses both the performance and environmental aspects of construction materials.

One of the key findings of the review is biochar’s internal curing capabilities. When incorporated into cement composites, biochar can retain water and release it gradually, promoting hydration product formation and improving the overall quality of the composite. This internal curing effect can lead to enhanced durability and reduced cracking, which are critical factors in the longevity of construction projects.

However, the path to widespread adoption of biochar in the construction industry is not without challenges. Variable biochar properties, optimal dosage, and scalability are among the hurdles that need to be addressed. “Standardization and further research are crucial to fully harness biochar’s potential as a sustainable component in low-carbon construction technologies,” Room emphasizes.

The commercial implications of this research are significant. As the energy sector increasingly focuses on sustainability and carbon reduction, the demand for low-carbon construction materials is expected to rise. Biochar-enhanced cement composites could become a key player in this market, offering a sustainable alternative to traditional cementitious materials.

Moreover, the internal curing capabilities of biochar could lead to cost savings in construction projects by reducing the need for external curing methods and minimizing maintenance costs associated with cracking and durability issues. This could make biochar-enhanced cement composites an attractive option for developers and contractors looking to balance performance, sustainability, and cost-effectiveness.

As the construction industry continues to evolve, the integration of biochar into cement composites could pave the way for more sustainable and resilient infrastructure. Room’s review serves as a catalyst for further research and innovation in this field, highlighting the need for collaboration between academia, industry, and policymakers to drive the adoption of biochar-enhanced cement composites.

In the words of Room, “The future of sustainable construction lies in innovative materials like biochar, which not only reduce our carbon footprint but also enhance the performance of our built environment.” As the industry moves towards a greener future, biochar-enhanced cement composites could well be a cornerstone of this transformation.