In the ever-evolving world of construction materials, a recent study has shed light on the potential of a unique combination of supplementary cementitious materials (SCMs) to enhance the mechanical and microstructural properties of concrete. The research, led by R.S. Ravichandran from the Department of Civil & Structural Engineering at Annamalai University in India, explores the synergistic effect of Alccofine and M-Sand as partial replacements for cement and natural sand, respectively.

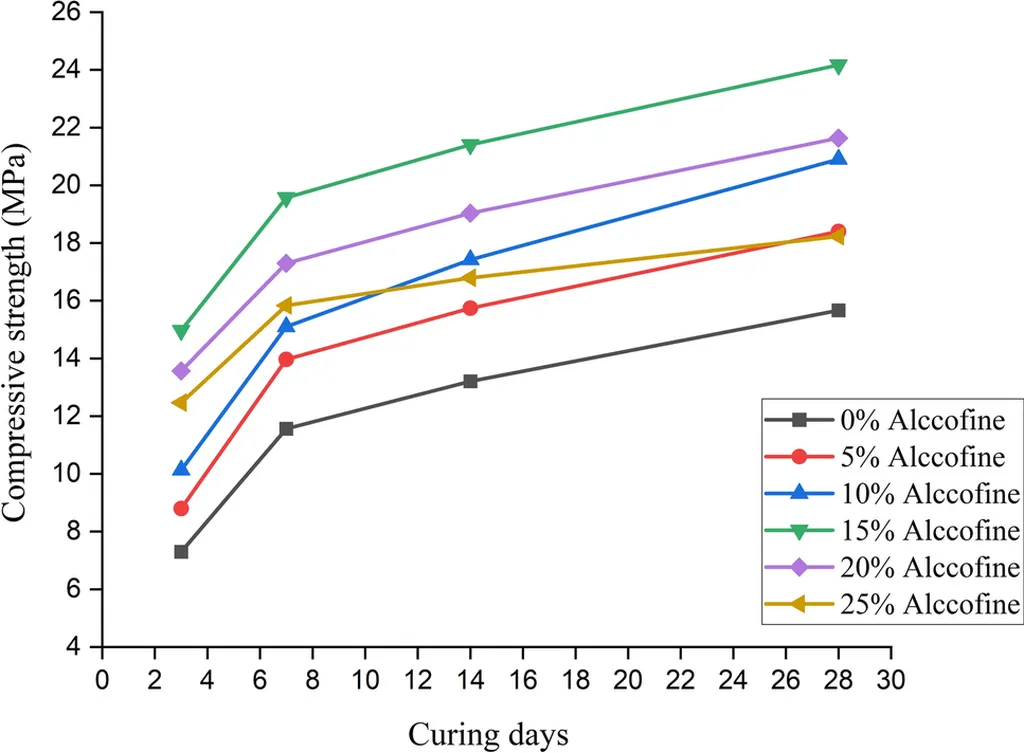

The study, published in the Journal of Sustainable Construction Materials and Technologies (which can be translated to English as “Journal of Sustainable Building Materials and Technologies”), delves into the impact of these materials on concrete’s strength and durability. Ravichandran and his team prepared six different mixes for both M25 and M40 grade concrete, substituting cement with Alccofine-1203 at varying levels (0 to 25%) and using M-Sand as a fine aggregate.

The results were promising. At a 20% replacement level of Alccofine, the concrete mixes exhibited significant improvements in compressive, split tensile, and flexural strength. “The concrete mixes containing 20% alccofine exhibited a more compact, resilient matrix and dense C-S-H gel formation,” Ravichandran noted, highlighting the enhanced strength properties of the mixes.

The study employed advanced techniques such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy dispersive spectroscopy (EDS) to investigate the microstructure of the concrete matrix. The XRD analysis revealed a high concentration of Anorthite, Portlandite, and Quartz peaks, indicating the formation of a dense and compact matrix.

The implications of this research are substantial for the construction industry, particularly in the energy sector where the demand for durable and high-performance concrete is ever-increasing. The use of Alccofine and M-Sand not only improves the mechanical properties of concrete but also contributes to sustainable construction practices by reducing the reliance on traditional cement and natural sand.

As the construction industry continues to seek innovative solutions to enhance the performance and sustainability of building materials, this research offers valuable insights into the potential of supplementary cementitious materials. The findings could pave the way for future developments in the field, shaping the way we build and construct in the years to come.

In the words of Ravichandran, “This study opens up new avenues for the use of supplementary cementitious materials in concrete, offering a sustainable and efficient alternative to traditional binders.” The journey towards sustainable construction is ongoing, and this research is a significant step in that direction.