In the quest for sustainable construction materials, researchers have long been exploring alternatives to traditional cementitious materials. A recent study published in the *Journal of Sustainable Construction Materials and Technologies* (translated from Turkish as *Journal of Sustainable Construction Materials and Technologies*) sheds light on the critical role of sodium hydroxide (NaOH) molarity in enhancing the mechanical properties and acid resistance of geopolymer mortars based on ground granulated blast furnace slag (GGBS). This research, led by Mahmoud Ziada from the Department of Civil Engineering at Istanbul Aydin University in Istanbul, Türkiye, offers promising insights for the construction and energy sectors.

Geopolymer mortars have gained traction as eco-friendly substitutes for conventional cement due to their lower carbon footprint and superior durability. However, optimizing their performance in harsh environments remains a challenge. Ziada’s study investigates how varying the molarity of NaOH—ranging from 6 M to 14 M—affects the mechanical strength and resistance to hydrochloric acid (HCl) of geopolymer mortars.

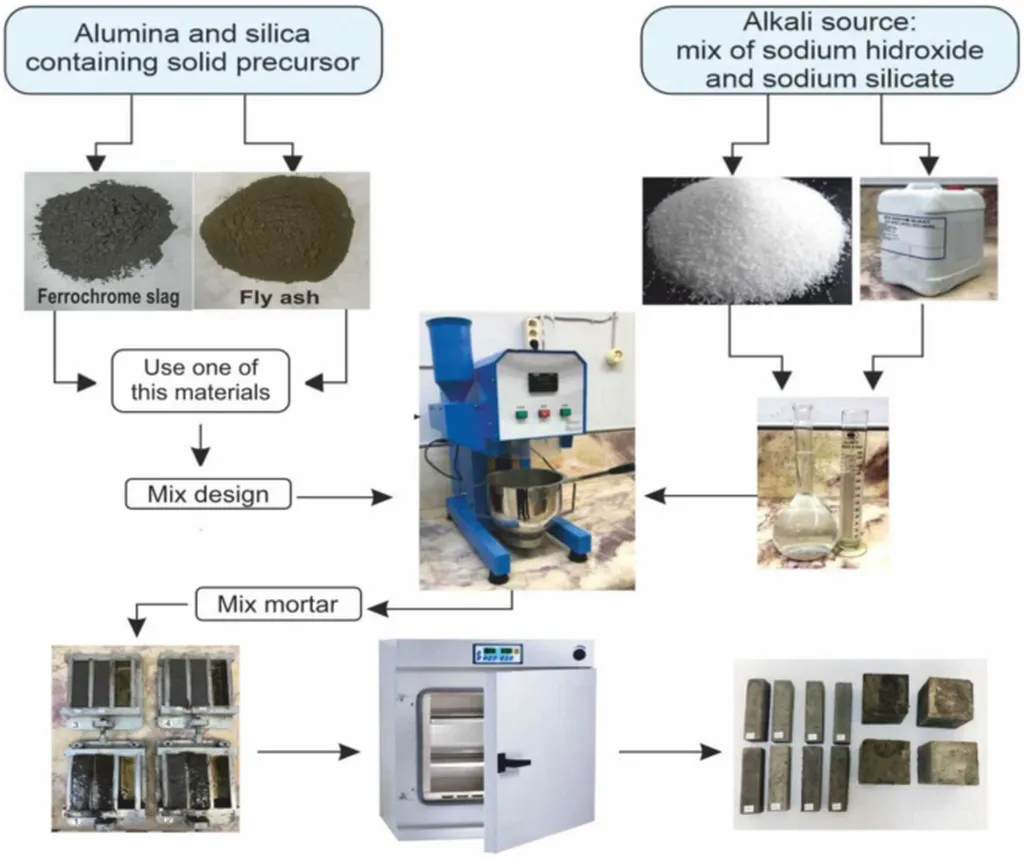

The research involved fabricating geopolymer mortar specimens with different NaOH molarities and subjecting them to a series of tests, including compressive strength, flexural strength, capillary water absorption, slump flow, and ultrasonic pulse velocity (UPV). The specimens were then exposed to a 5% HCl solution for 28 days to assess their acid resistance.

The results were striking. After 28 days of HCl exposure, the compressive strength of the geopolymer mortar containing 10 M NaOH increased by 59.63% compared to the 6 M sample. However, this enhancement tapered off in the 14 M sample, which showed a 43.84% increase. “The molarity of NaOH substantially affects both mechanical strength and resistance to acid degradation,” Ziada noted. “This work highlights the essential significance of NaOH molarity in optimizing geopolymer formulations for use in harsh settings.”

The findings suggest that there is a delicate balance between strength enhancement and durability. For the energy sector, this research could have significant implications. Geopolymer mortars with optimized NaOH molarity could be used in environments where exposure to acids is a concern, such as in chemical plants, wastewater treatment facilities, and other industrial settings. The enhanced durability and mechanical properties could lead to longer-lasting structures, reducing maintenance costs and improving safety.

Moreover, the study provides a roadmap for future research. “Understanding the interplay between NaOH molarity and geopolymer performance is crucial for developing materials that can withstand extreme conditions,” Ziada explained. “This research opens the door to further exploration of geopolymer formulations and their applications in various industries.”

As the construction industry continues to seek sustainable and durable materials, geopolymer mortars offer a promising alternative. Ziada’s research underscores the importance of optimizing NaOH molarity to achieve the best possible performance. With further advancements, geopolymer mortars could become a standard in construction, particularly in sectors where durability and resistance to harsh chemicals are paramount. The study, published in the *Journal of Sustainable Construction Materials and Technologies*, is a step forward in this direction, providing valuable insights for engineers, researchers, and industry professionals alike.