In a groundbreaking study that could reshape the construction and energy sectors, researchers have discovered a novel method to transform steel slag into high-strength, eco-friendly building materials while significantly enhancing CO2 mineralization. The research, led by Ziping Pan from the Key Laboratory of Efficient Mining and Safety of Metal Mines at the University of Science and Technology Beijing, explores the effects of temperature on the carbonation consolidation of steel slag using ammonium carbonate solution.

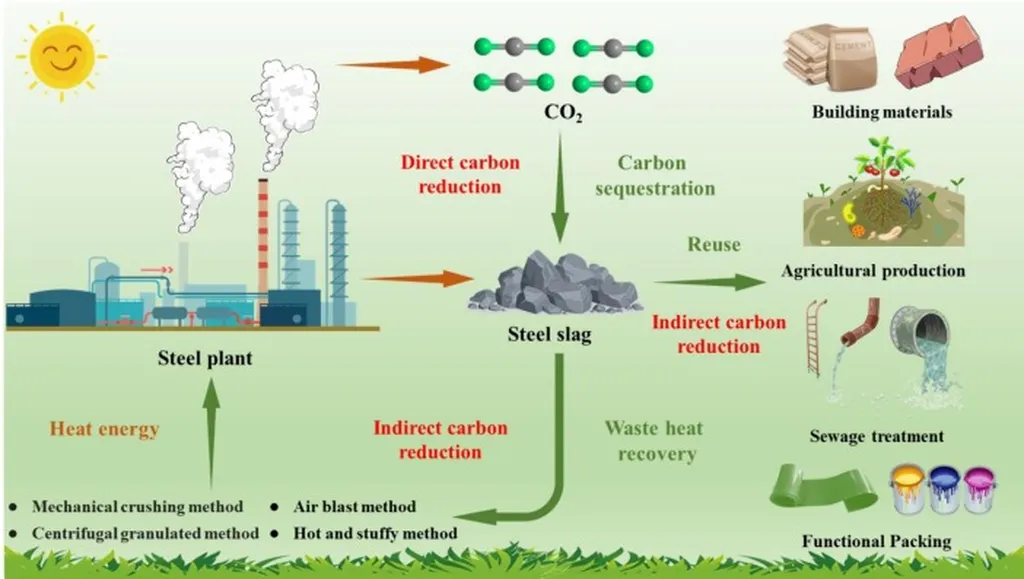

Steel slag, a byproduct of steel production, has long been an environmental challenge due to its large-scale generation and limited applications. However, Pan’s study, published in the *Journal of Materials Research and Technology* (translated as *Journal of Materials Science and Technology*), reveals that by curing steel slag at elevated temperatures, its compressive strength and carbonation conversion can be dramatically improved. “Higher temperatures significantly accelerate the reaction kinetics, leading to the formation of stronger carbonation-hydration products,” Pan explains. This process not only enhances the material’s strength but also its potential for CO2 sequestration, a critical factor for the energy sector aiming to reduce carbon emissions.

The study found that curing steel slag at 60°C resulted in a peak compressive strength of 118.38 MPa, a remarkable 114% increase compared to curing at 20°C. This enhancement is attributed to the increased dissolution of Ca2+, improved calcium carbonate crystallinity, and the development of denser microstructures at higher temperatures. The addition of ammonium carbonate further aids in mass transfer and Ca2+ extraction, introducing a new mineralization pathway involving carbamate ions.

The implications of this research are profound for both the construction and energy industries. By optimizing the carbonation process of steel slag, the study provides a theoretical and experimental basis for developing sustainable building materials with significant CO2 sequestration potential. “This method offers a promising solution for reducing the environmental impact of steel production while creating valuable construction materials,” Pan notes.

As the world seeks innovative ways to mitigate climate change, this research highlights the importance of leveraging industrial byproducts for sustainable development. The findings could pave the way for future advancements in the field, encouraging further exploration of temperature-regulated processes and alternative curing agents to enhance material performance and environmental benefits.