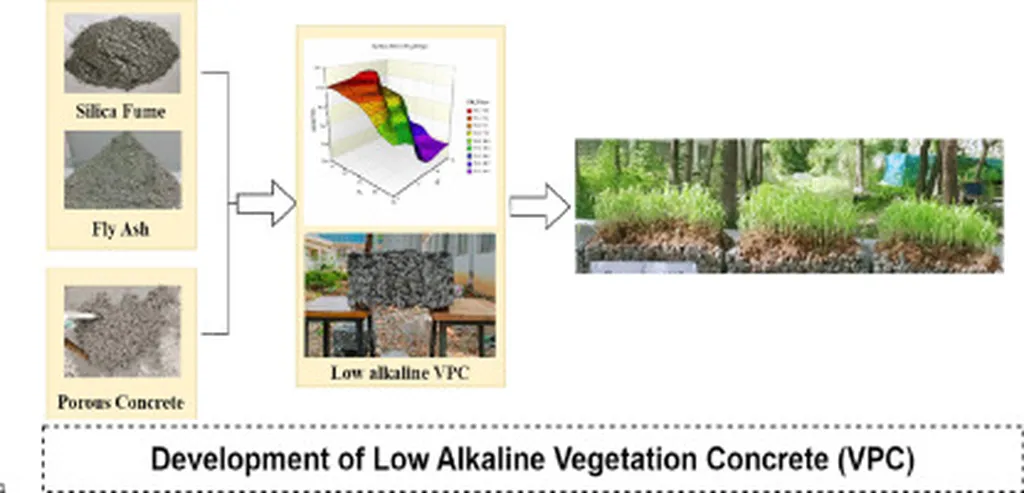

In the quest for sustainable urban infrastructure, a groundbreaking study has emerged that could redefine the way we manage stormwater and construct our cities. Researchers, led by Siva Shanmukha Anjaneya Babu Padavala from the Department of Civil Engineering at Gudlavalleru Engineering College in India, have explored the potential of pervious concrete (PC) enhanced with fly ash (FA) and silica fume (SF) to improve both mechanical performance and environmental sustainability. The findings, published in the journal ‘Next Materials’ (which translates to ‘New Materials’), offer promising insights for the construction and energy sectors.

Pervious concrete, known for its porous nature, has long been recognized for its ability to facilitate stormwater drainage, reducing runoff and alleviating pressure on urban drainage systems. However, its mechanical properties have often limited its widespread adoption. Padavala and his team set out to address this challenge by incorporating fly ash and silica fume as supplementary cementitious materials (SCMs).

The study involved extensive experimental investigations, testing various replacement levels of FA and SF to determine the optimal mix proportions. The results were striking. A blend containing 30% fly ash and 10% silica fume achieved a 28-day compressive strength of 34 MPa, representing a 51.1% increase over the control mix. This enhanced strength was accompanied by improved flexural and tensile strengths, reduced porosity, and maintained high permeability.

“Our findings demonstrate a significant improvement in the mechanical properties of pervious concrete through the use of fly ash and silica fume,” said Padavala. “This not only enhances the durability and longevity of the material but also contributes to a more sustainable construction process.”

The environmental benefits are equally compelling. The optimized mix resulted in a 4.7% reduction in CO₂ emissions and 6.19% lower material costs, making it a cost-effective and eco-friendly solution for urban infrastructure.

To further validate their findings, the researchers employed machine learning (ML) models to predict compressive strength based on mix composition and curing age. Five algorithms were trained and evaluated, with Support Vector Machine (SVM) achieving the highest predictive accuracy.

“This research not only validates the synergy of SCMs in enhancing PC performance but also supports their practical application in urban infrastructure such as pedestrian pavements, permeable roads, and stormwater infiltration systems,” Padavala added.

The implications of this research are far-reaching. For the construction industry, the enhanced mechanical properties and sustainability of pervious concrete offer a viable solution for urban stormwater management. For the energy sector, the reduced CO₂ emissions and material costs present opportunities for more sustainable and cost-effective construction practices.

As cities around the world grapple with the challenges of urbanization and climate change, the findings of this study provide a beacon of hope. By embracing innovative materials and technologies, we can build more resilient and sustainable urban environments.

In the words of Padavala, “This is just the beginning. The potential for further research and development in this area is immense, and we are excited to be at the forefront of this transformative journey.”