In the quest for sustainable construction materials, researchers have turned to an unlikely ally: rubber. Discarded rubber, often destined for landfills, is being repurposed to create rubberized mortar (RM), a promising alternative that promotes circular economy principles. However, the reduced compressive strength of RM due to rubber inclusion has hindered its widespread adoption. Enter Fu Limei, a researcher from the Accounting College at Hainan Vocational University of Science and Technology, who has pioneered a data-driven approach to predict and optimize the strength performance of RM.

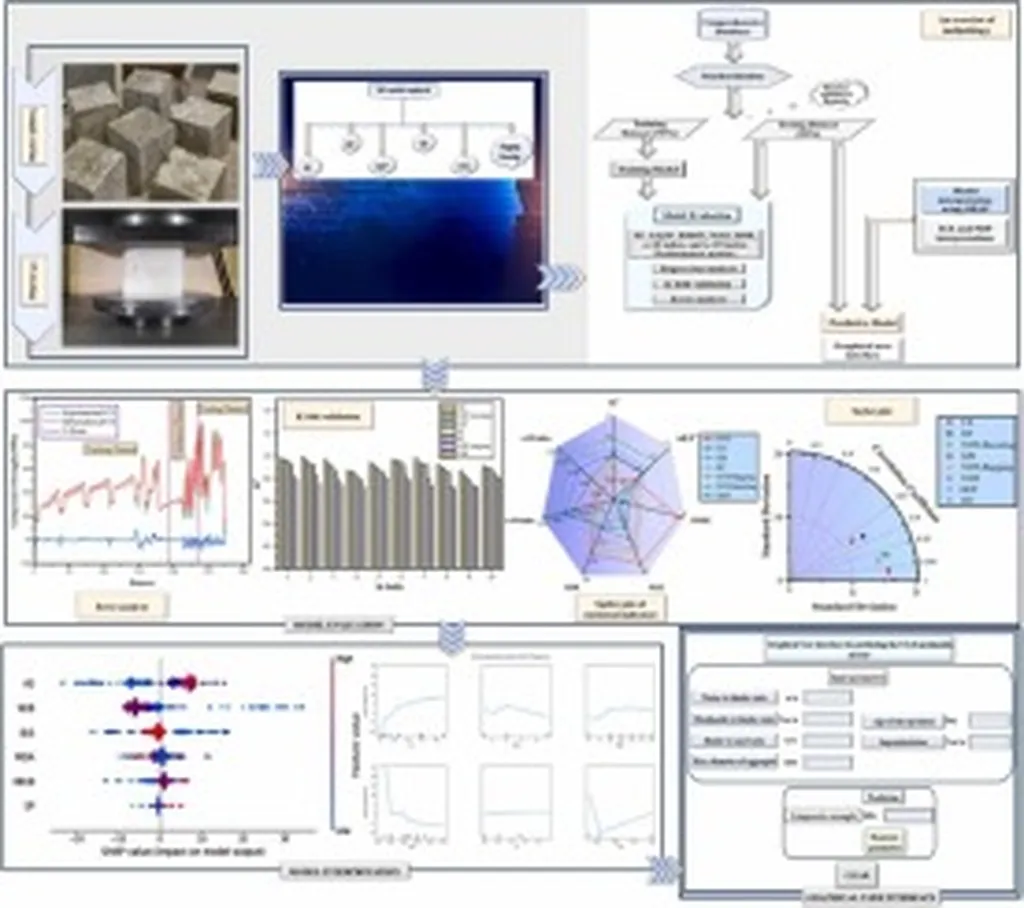

Fu Limei and her team have harnessed the power of machine learning to address this challenge. “We wanted to move beyond traditional experimental methods and leverage data-driven strategies to efficiently predict the compressive strength of rubberized mortar,” Fu explains. The team evaluated various machine learning algorithms, including bagging, gradient boosting, and AdaBoost, to find the most accurate predictor.

The results were impressive. The bagging model emerged as the top performer, achieving an accuracy of R² = 0.975. This high accuracy is a game-changer for the construction industry, enabling engineers and material designers to develop sustainable RM mixes with improved performance. “Our findings can significantly reduce the reliance on extensive laboratory testing, saving time and resources,” Fu adds.

The research also identified cement and sand content as the most influential variables affecting compressive strength, thanks to SHapley Additive exPlanations (SHAP) analysis. This insight provides a clearer understanding of the material’s behavior, paving the way for optimized formulations.

The practical implications of this research are substantial. By integrating the findings into a graphical user interface, the team has created a tool for real-time strength estimation. This tool can support engineers and material designers in creating more sustainable and efficient construction materials, ultimately benefiting the energy sector by promoting greener building practices.

The study, published in ‘Reviews on Advanced Materials Science’ (translated to English as ‘Advanced Materials Science Reviews’), marks a significant step forward in the field of sustainable construction materials. As the construction industry continues to seek eco-friendly alternatives, this research offers a promising path towards achieving both sustainability and performance.

The potential impact of this research extends beyond the construction sector. By demonstrating the effectiveness of machine learning in material science, it opens new avenues for data-driven innovation. “This is just the beginning,” Fu notes. “We believe that similar approaches can be applied to other materials and industries, driving forward the circular economy.”

In an era where sustainability and efficiency are paramount, Fu Limei’s research provides a compelling example of how advanced AI tools can shape the future of construction. By bridging the gap between experimental studies and practical applications, this work sets a new standard for sustainable material development.