In the ever-evolving world of construction materials, a groundbreaking study led by Khan Kaffayatullah from the Department of Civil and Environmental Engineering at King Faisal University in Saudi Arabia is set to revolutionize the way we approach sustainable concrete design. The research, published in the esteemed journal “Reviews on Advanced Materials Science” (translated as “Reviews on Advanced Materials Science”), focuses on the predictive modeling of self-compacting concrete (SCC) enhanced with industrial waste materials like marble and glass powders.

Self-compacting concrete is already a game-changer in modern construction, known for its ability to flow and compact under its own weight, eliminating the need for mechanical vibration. This not only improves construction quality but also speeds up the process. However, the challenge lies in predicting the compressive strength of these mixes, a crucial factor in determining the structural integrity of buildings. Traditional testing methods are time-consuming and costly, often hindering rapid mix optimization.

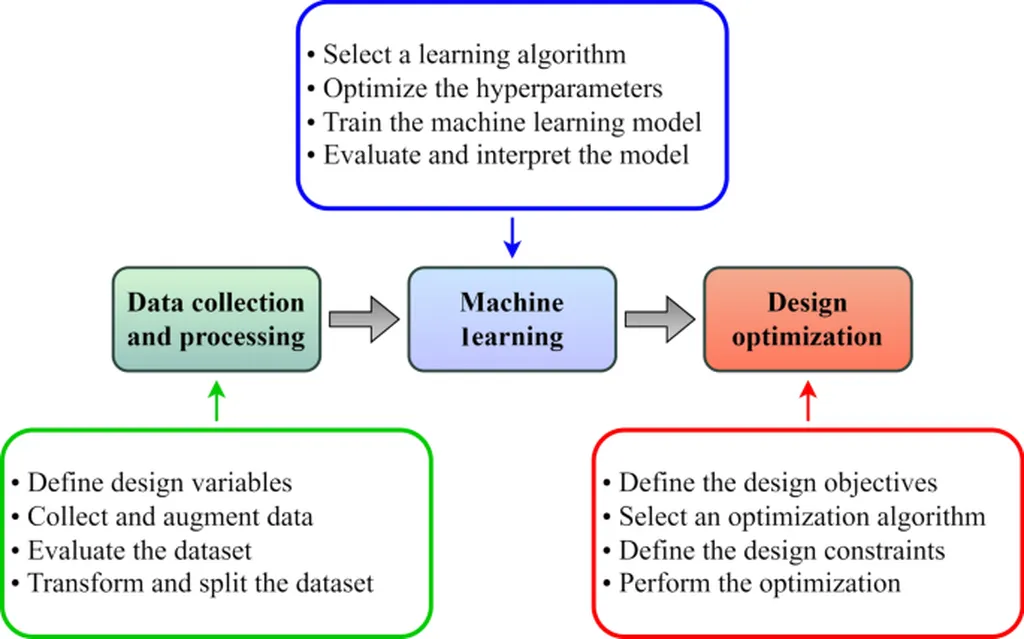

Enter machine learning (ML), a powerful tool that can analyze complex datasets and identify patterns influencing concrete performance. Kaffayatullah and his team employed three ML models—gradient boosting, bagging regression, and random forest (RF)—to predict the compressive strength of SCC incorporating marble and glass powders. The results were impressive, with the random forest model achieving the highest accuracy, boasting an R² value of 0.95.

“The random forest model’s superior performance was a significant breakthrough,” Kaffayatullah explained. “It not only provided highly accurate predictions but also offered insights into the key factors influencing the compressive strength of these sustainable concrete mixes.”

The study didn’t stop at prediction. It delved deeper into model interpretability using Shapley Additive exPlanations, partial dependence plots, and individual conditional expectation analyses. These tools identified curing time as the most influential feature, a critical insight for optimizing mix designs.

For the energy sector, the implications are substantial. The ability to rapidly and accurately predict the performance of sustainable concrete mixes can significantly reduce the environmental impact of construction projects. By incorporating industrial waste materials like marble and glass powders, the construction industry can reduce its reliance on traditional, resource-intensive materials.

“This research highlights the potential of machine learning not only as a predictive tool but also as a means of understanding key factors in sustainable mix design,” Kaffayatullah noted. “It’s a step towards smarter and greener construction practices.”

The study’s findings, published in “Reviews on Advanced Materials Science,” pave the way for future developments in the field. As the construction industry continues to seek sustainable solutions, the integration of machine learning techniques offers a promising path forward. By embracing these technologies, the industry can achieve faster, more accurate, and more sustainable mix designs, ultimately contributing to a greener future.

In the words of Kaffayatullah, “The future of construction lies in the intersection of sustainability and technology. This research is a testament to that.” As we look ahead, the potential for machine learning in construction is vast, and the possibilities are endless.