In the heart of Canada’s vast forestry region, researchers are turning construction waste into a powerful tool for environmental remediation, offering a promising solution for industries grappling with wastewater treatment challenges. Aziz Bentis, a researcher at the University of Québec in Abitibi-Témiscamingue’s Forest Research Institute (Institut de Recherche sur les Forêts, IRF), has led a study that transforms wood panel waste (WPW) into activated biochar, a highly effective adsorbent for removing phenol from water.

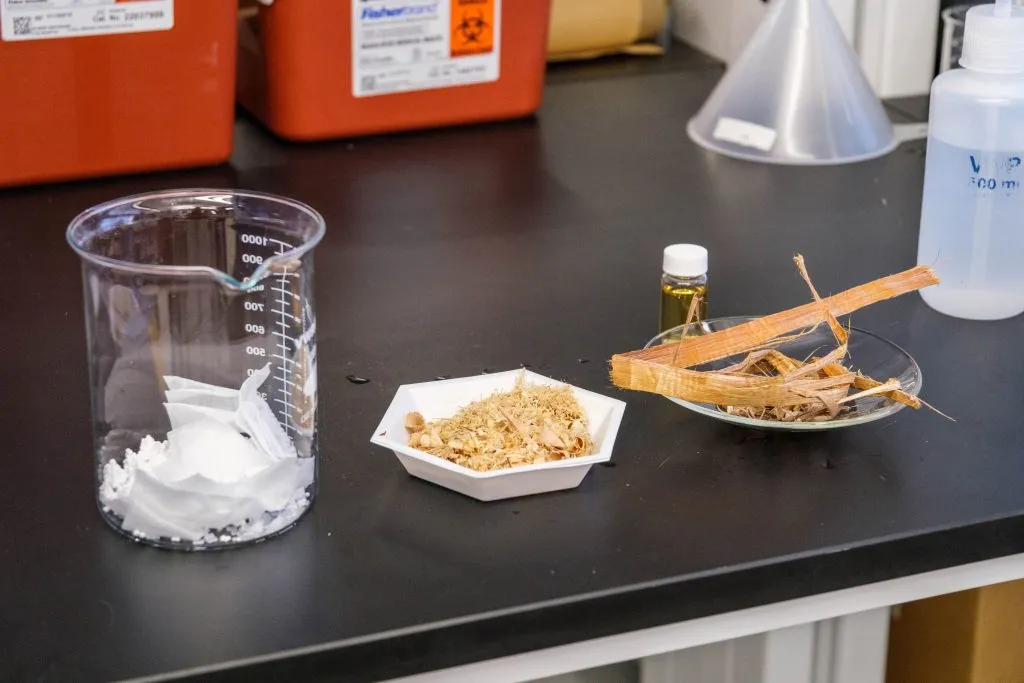

The construction and demolition industries generate substantial amounts of wood panel waste, posing environmental challenges. However, Bentis and his team saw an opportunity for sustainable resource recovery. “We wanted to find a way to valorize this waste material, turning it into something useful and beneficial for the environment,” Bentis explained.

The team produced biochar through pyrolysis at 450 °C and then activated it at varying temperatures of 750, 850, and 950 °C. The results were striking. The activated biochar demonstrated up to nine times higher adsorption capacity than raw biochar, with a maximum adsorption capacity of 171.9 mg/g at 950 °C. This means that a small amount of biochar can remove a significant quantity of phenol from water, making it a highly efficient and cost-effective solution for wastewater treatment.

The study, published in the journal Applied Sciences (translated from French), revealed that the adsorption process followed a pseudo-second-order model and fit the Langmuir isotherm, indicating that the phenol adsorption mechanism is chemisorption and monolayer adsorption. This means that the phenol molecules form strong chemical bonds with the biochar surface, creating a uniform layer that maximizes adsorption capacity.

One of the most compelling aspects of this research is its alignment with circular economy and green chemistry principles. By converting waste material into a valuable resource, this study demonstrates how industries can reduce waste, conserve resources, and minimize environmental impact. “This is not just about finding a use for waste material,” Bentis said. “It’s about creating a sustainable cycle where waste becomes a resource, and resources are used efficiently and responsibly.”

The commercial implications for the energy sector are significant. Phenol is a common pollutant in wastewater from various industries, including oil and gas, petrochemical, and pharmaceutical. Effective phenol removal is crucial for meeting environmental regulations and protecting public health. The activated biochar developed by Bentis and his team offers an eco-friendly and efficient solution for phenol adsorption, potentially reducing treatment costs and improving environmental performance.

Moreover, the study confirmed the environmental safety of the biochar through leaching tests, with heavy metal concentrations well below regulatory limits. This ensures that the biochar not only effectively removes pollutants but also does not introduce new contaminants into the environment.

As industries increasingly prioritize sustainability and circular economy practices, research like Bentis’s offers a glimpse into the future of waste management and environmental remediation. By turning waste into a valuable resource, industries can reduce their environmental footprint, conserve resources, and create new economic opportunities. The activated biochar developed by Bentis and his team is a testament to the power of innovation and the potential of waste materials to drive sustainable development.

In the words of Bentis, “This research is just the beginning. There is so much more we can do with waste materials, and I am excited to see how this work will inspire further innovation in the field.” As industries continue to seek sustainable solutions, the insights from this study will undoubtedly shape future developments in wastewater treatment and environmental remediation.