In the quest for sustainable construction materials, researchers have turned to an unlikely ally: discarded tires and demolition debris. A recent study led by Yaqoob Saif from the Geomaterials, Civil Engineering Structures and Environment Laboratory (GESTE) at the National School of Engineering of Sfax, Tunisia, explores the potential of self-compacting concrete (SCC) incorporating rubber and recycled aggregates for non-structural applications. The findings, published in the journal ‘Buildings’ (which translates to ‘Buildings’ in English), offer promising insights into the future of eco-friendly construction materials.

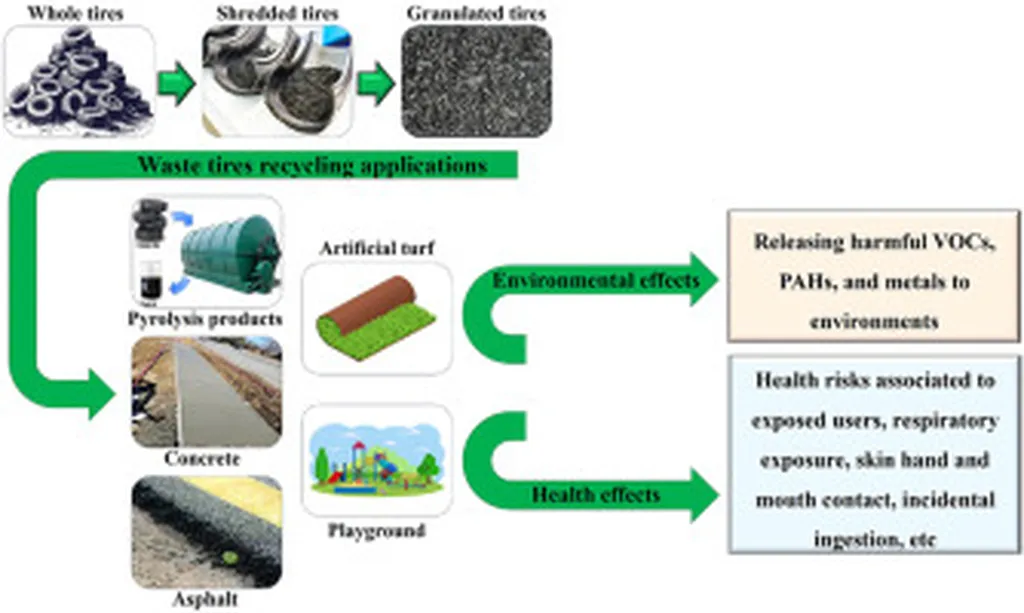

The study addresses a pressing environmental challenge: the accumulation of end-of-life tires and the rapid increase in demolition activities. By incorporating these waste materials into SCC, the research team aims to minimize environmental impact and promote a circular economy. “The redevelopment of construction materials incorporating this waste is a potentially promising strategy,” Saif explains. “It’s about turning a problem into a resource.”

The researchers conducted a series of tests to assess the fresh and hardened properties of SCC incorporating up to 20% rubber aggregates (both sand and gravel) and 40% recycled concrete aggregate (RCA). The results were promising yet nuanced. Increasing RCA content reduced the density and compressive strength of the concrete, while tensile and flexural strengths were only moderately affected. “This shows that while recycled materials can impact strength, they don’t necessarily compromise the overall performance of the concrete,” Saif notes.

To optimize the mechanical performance of the SCC, the team employed response surface methodology (RSM) utilizing a Box–Behnken design. This statistical approach helped identify the optimal mix proportions, balancing mechanical performance and sustainability. Mixtures incorporating moderate amounts of rubber—specifically, 5–5.5% sand rubber and 0–6% coarse rubber—along with 40% RCA achieved the highest predicted performance. These mixtures demonstrated compressive strengths ranging from 20.00 to 28.26 MPa, tensile strengths from 2.16 to 2.85 MPa, and flexural strengths reaching 5.81 MPa, making them suitable for sidewalks and walkways.

Conversely, mixtures with higher rubber proportions (5.5–20% sand rubber and 20% coarse rubber) combined with the same RCA level (40%) showed the lowest mechanical performance. These findings underscore the broad performance range achievable through targeted optimization. “It’s about finding the right balance,” Saif emphasizes. “Too much rubber can compromise strength, but moderate amounts can work effectively.”

The implications for the construction industry are significant. By utilizing recycled materials, builders can reduce waste and lower the environmental footprint of their projects. This is particularly relevant for non-structural applications, where the mechanical performance requirements are less stringent. “This research confirms the viability of recycled materials for producing environmentally friendly SCC,” Saif concludes. “It’s a step towards a more sustainable future.”

As the construction industry continues to grapple with environmental challenges, innovations like these offer a glimmer of hope. By turning waste into valuable resources, researchers are paving the way for a more sustainable and circular economy. The study by Saif and his team is a testament to the power of innovation and the potential of recycled materials in shaping the future of construction.