In the quest for sustainable construction materials, researchers have turned their attention to an unlikely candidate: dealuminated metakaolin (DK), a waste product from the aluminium sulphate industry. A recent review published in the journal *Applied Sciences* (translated from Latin as “Applied Sciences”) sheds light on the potential of DK to revolutionize the cement and concrete industry, offering a promising avenue for waste valorization and reduced carbon emissions.

Dr. Mostafa Elsebaei, a researcher at the School of Engineering and Design at London South Bank University, led the comprehensive review that evaluates DK’s potential as a component in cementitious systems. “The idea is to transform a hazardous industrial by-product into a valuable resource,” Elsebaei explains. “This aligns with the principles of a circular economy, where waste is minimized, and resources are kept in use for as long as possible.”

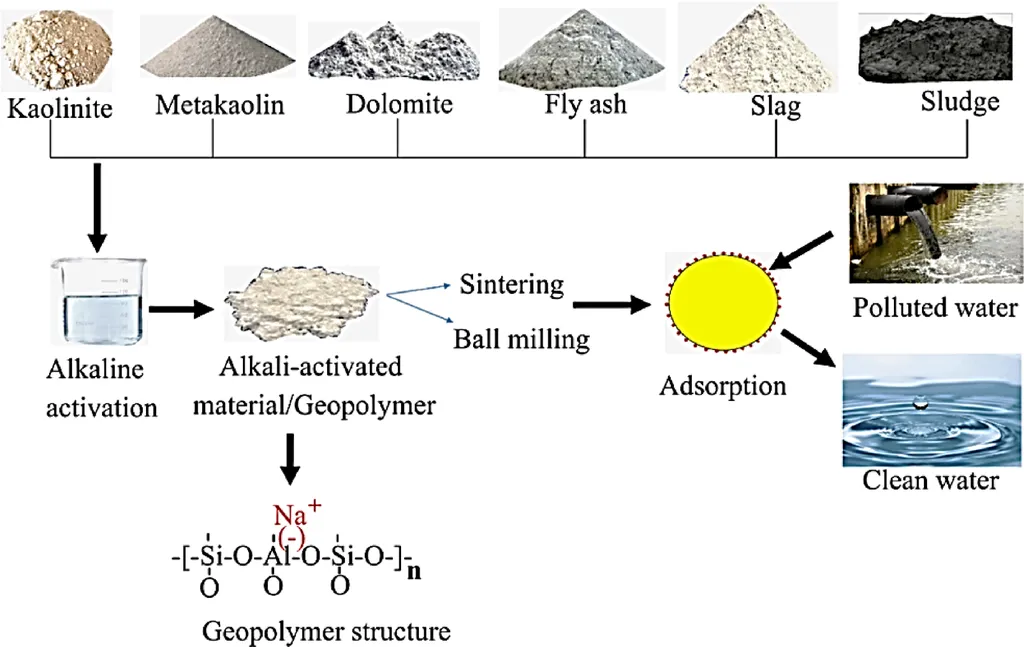

The review delves into the formation, properties, and reactivity of DK, particularly its pozzolanic potential, which makes it suitable for use as a supplementary cementitious material (SCM) or as a precursor in alkali-activated cement (AAC) systems. “DK can partially or even fully replace Portland cement (PC) in certain applications,” Elsebaei notes. “This is a significant step towards reducing the environmental footprint of the construction industry.”

The construction industry is one of the largest emitters of greenhouse gases, with cement production alone accounting for about 8% of global CO2 emissions. The integration of DK into cementitious systems could significantly mitigate these emissions. “By reducing the need for clinker, the main component of PC, we can lower the carbon footprint of concrete production,” Elsebaei explains. “This is not just about economic benefits; it’s about environmental stewardship.”

The review also highlights the scientific gaps and practical challenges that limit the broader adoption of DK. “While the potential is there, we need more research to optimize the use of DK in different applications,” Elsebaei says. “This includes understanding its long-term performance, durability, and compatibility with other materials.”

The findings of this review could shape future developments in the field, promoting the integration of DK into efforts to enhance the sustainability of construction practices. “This is a call to action for researchers and industry stakeholders,” Elsebaei concludes. “We need to collaborate to overcome the challenges and unlock the full potential of DK.”

As the construction industry grapples with the need to reduce its environmental impact, the insights from this review offer a beacon of hope. By valorizing industrial waste and reducing reliance on traditional cement, the industry can move towards a more sustainable and circular future. The journey is just beginning, but the potential is immense, and the stakes are high. The time to act is now.