In a significant stride towards sustainable construction, researchers have unveiled a promising alternative to traditional masonry materials, with implications that could reshape the energy efficiency landscape of the built environment. The study, led by G. Nakkeeran from the Department of Civil Engineering at Madanapalle Institute of Technology & Science, explores the mechanical and thermal performance of Bio-Bricks—an innovative construction material derived from groundnut shell waste (GNS) and hydrated lime mortar.

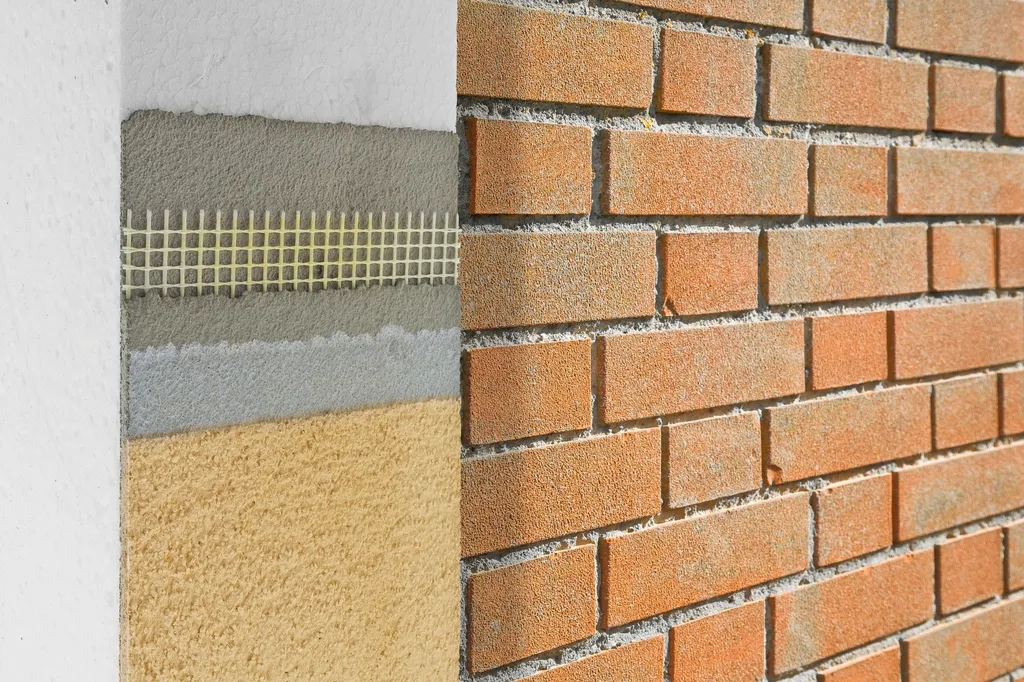

The construction sector’s growing emphasis on sustainability and thermal efficiency has prompted a shift toward eco-compatible masonry materials. This experimental investigation explores the mechanical and thermal behavior of Bio-Bricks composed of groundnut shell waste (GNS) and hydrated lime mortar under elevated temperature conditions. The study comprehensively evaluates the compressive and shear performance of masonry prisms, as well as heat resistance through prototype wall models. Results reveal that Bio-Bricks combined with hydrated lime mortar deliver a significant enhancement of 7.9% in compressive strength and 12.6% in shear strength over conventional systems. Thermal evaluations demonstrate a reduced indoor heat flux ranging from 8 to 15°C, indicating superior insulation performance. Furthermore, finite element simulations closely validate experimental results, confirming the reliability of Bio-Brick assemblies under thermal and mechanical stress. The integration of agricultural by-products and pozzolanic binders highlights the potential of Bio-Bricks as a sustainable alternative, promoting energy efficiency and structural reliability in modern construction.

The research, published in the journal *Scientific Reports* (translated from its original name, *Nature Scientific Reports*), demonstrates that Bio-Bricks offer a substantial improvement in both mechanical and thermal performance compared to conventional masonry materials. “The integration of agricultural by-products and pozzolanic binders highlights the potential of Bio-Bricks as a sustainable alternative,” Nakkeeran explained, emphasizing the dual benefits of waste reduction and enhanced structural performance.

The study’s findings are particularly relevant to the energy sector, as improved thermal insulation in buildings can significantly reduce energy consumption for heating and cooling. With indoor heat flux reduced by 8 to 15°C, Bio-Bricks could play a pivotal role in creating more energy-efficient structures, aligning with global sustainability goals.

The commercial implications are substantial. As the demand for eco-friendly and energy-efficient construction materials grows, Bio-Bricks could emerge as a viable alternative to traditional materials, offering both environmental and economic advantages. The study’s validation through finite element simulations further underscores the reliability of Bio-Brick assemblies, paving the way for their adoption in modern construction projects.

This research not only highlights the potential of Bio-Bricks but also sets the stage for future developments in sustainable construction. As the industry continues to seek innovative solutions to reduce its environmental impact, the integration of agricultural by-products and pozzolanic binders could become a cornerstone of modern masonry, promoting energy efficiency and structural reliability.

In conclusion, the study led by Nakkeeran offers a compelling vision of the future of construction, where sustainability and performance go hand in hand. As the world grapples with the challenges of climate change and resource depletion, Bio-Bricks represent a beacon of hope, demonstrating that innovative solutions can emerge from the most unexpected sources.