In the quest for sustainable construction solutions, researchers have turned their attention to an unlikely hero: flue gas desulfurization (FGD) gypsum, a byproduct of coal-fired power plants. A recent study published in the journal *Scientific Reports* (translated from English as “Scientific Reports”) demonstrates how this industrial waste can be repurposed to stabilize problematic black cotton (BC) soil, offering a promising avenue for green construction practices.

Black cotton soil, known for its high shrink-swell behavior, poses significant challenges in construction and pavement applications. To tackle this issue, Chidananda M. Linganagoudar from the Department of Civil Engineering at Dayananda Sagar College of Engineering led a study exploring the use of FGD gypsum and cement as stabilizing agents. The research employed response surface methodology (RSM) to optimize mix proportions and assess their effects on soil properties.

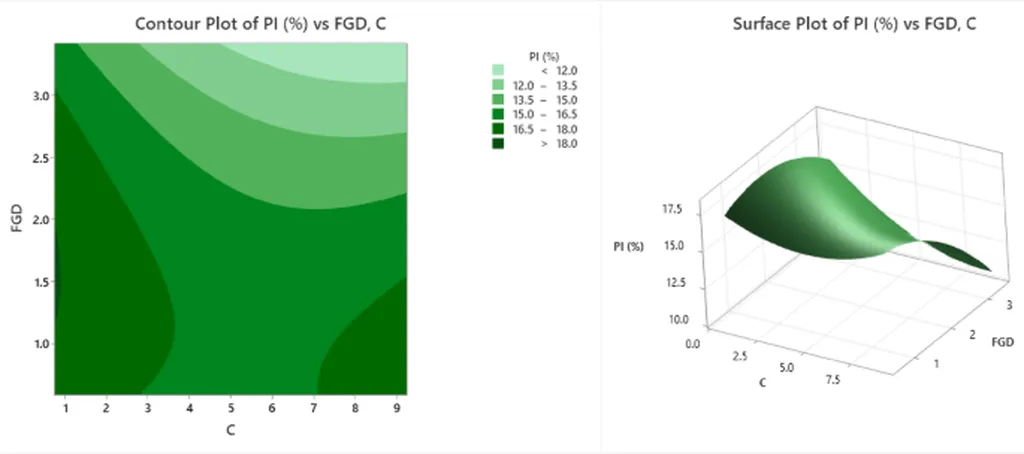

The study found that the combination of 9.24% cement and 3.41% FGD gypsum significantly enhanced the soil’s unconfined compressive strength (UCS) and California bearing ratio (CBR), while substantially reducing its plasticity index (PI). “The optimum mixture yielded a desirability score of 71%, indicating an effective balance between strength gain and workability,” Linganagoudar explained. This finding underscores the potential of FGD gypsum as a sustainable and eco-friendly soil stabilizer.

The implications for the energy sector are substantial. By repurposing FGD gypsum, power plants can reduce waste disposal costs and generate additional revenue streams. Moreover, the use of industrial byproducts in construction aligns with circular economy principles, promoting sustainability and resource efficiency.

“This research opens up new possibilities for the energy sector to contribute to sustainable infrastructure development,” Linganagoudar noted. “It’s a win-win situation: we’re improving soil stability for construction while also finding a beneficial use for an industrial byproduct.”

The study’s findings contribute to advancing green construction practices and offer an economical and efficient method for improving subgrade performance in flexible pavement systems. As the demand for sustainable infrastructure solutions grows, this research could shape future developments in geotechnical engineering and pave the way for innovative applications of industrial byproducts in construction.