In the quest for sustainable construction materials, researchers have turned to an unlikely ally: glass powder. A recent study led by Muhammad Sarmad Mahmood from the Department of Civil Engineering at the Swedish College of Engineering and Technology (SWECOET) has harnessed the power of machine learning to optimize high-strength concrete incorporating glass powder, potentially revolutionizing the construction industry’s approach to sustainable materials.

The study, published in *Scientific Reports* (translated from Swedish as “Scientific Reports”), addresses a critical challenge in the construction industry: achieving high-strength concrete (HSC) with sustainable supplementary cementitious materials (SCMs). Glass powder, a byproduct of the glass industry, has emerged as a promising partial cement substitute. However, its specific impact on HSC growth has remained unclear until now.

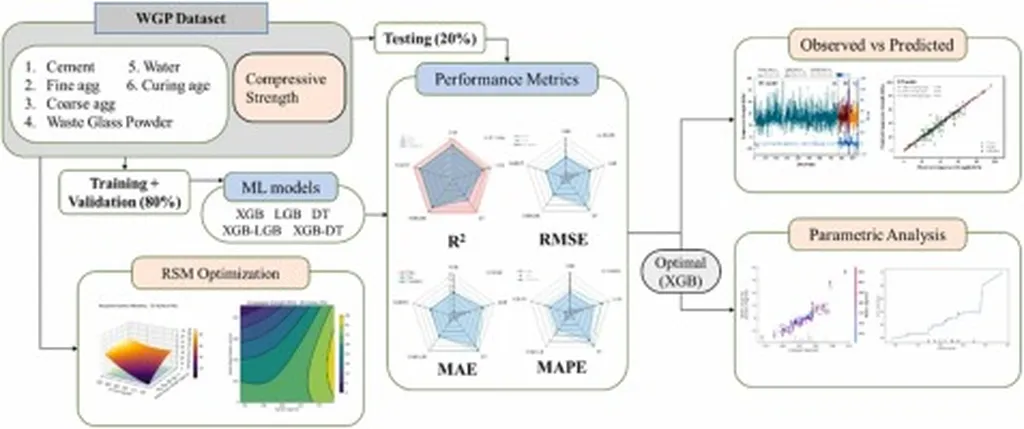

Mahmood and his team compiled a dataset comprising 598 data points, considering key input parameters such as cement, glass powder, aggregates, water, superplasticizer, and curing days. They trained three machine learning models—K-Nearest Neighbors (KNN), Random Forest (RF), and Extreme Gradient Boosting (XGB)—to evaluate the compressive strength (CS) of high-strength glass-powder concrete (HSGPC). The Random Forest model achieved an impressive R² value of 0.963, while the Extreme Gradient Boosting model reached R² of 0.946 on the test set.

To further enhance predictive accuracy, the team optimized the XGB model using hybrid optimization techniques, including Particle Swarm Optimization (PSO), Firefly Algorithm (FA), and Grey Wolf Optimizer (GWO). The XGB-GWO combination demonstrated the highest accuracy, with R² improving to 0.991 and Mean Squared Error (MSE) decreasing significantly from 83.95 to 14.42, resulting in an 82.82% error reduction.

The study employed SHAP (SHapley Additive exPlanations), PDP (Partial Dependence Plots), and ICE (Individual Conditional Expectation) analyses to identify the most influential parameters affecting compressive strength. Superplasticizer dosage, curing days, and coarse aggregate emerged as the top factors. “These analyses not only validated our findings but also provided a deeper understanding of how each parameter interacts with the others,” Mahmood explained.

The implications of this research are profound for the construction industry, particularly in the energy sector. As the demand for sustainable and high-performance materials grows, the ability to optimize concrete mixtures using machine learning can lead to significant advancements. “This study highlights the potential of ML-driven optimization for sustainable concrete design, offering an efficient, data-driven approach to optimizing material proportions for high-strength, eco-friendly concrete,” Mahmood stated.

The findings suggest that beyond 600 kg/m³ of cement and 800 kg/m³ of coarse aggregate, the strength gains diminish. This insight can guide construction professionals in making informed decisions about material proportions, ultimately leading to more sustainable and cost-effective construction practices.

As the construction industry continues to evolve, the integration of machine learning and optimization techniques holds promise for developing innovative, sustainable materials. Mahmood’s research paves the way for future advancements in the field, offering a blueprint for leveraging data-driven approaches to address critical challenges in construction.

In an era where sustainability and performance are paramount, this study serves as a testament to the power of interdisciplinary research and the potential of machine learning to transform traditional industries. As Mahmood and his team continue to explore the possibilities, the construction industry stands to benefit from more efficient, sustainable, and high-performance materials.