In the quest for sustainable construction materials, a recent study published in the journal *Scientific Reports* (translated from the original Chinese title) has uncovered promising advancements that could reshape the industry’s approach to recycled aggregates. Led by Anmol Basnett from the Department of Civil Engineering at SRM Institute of Science and Technology, the research delves into the influence of bond strength in treated mixed recycled aggregate concrete, particularly when incorporating olivine sand.

The study explores three distinct concrete mixes: Mixed Recycled Aggregate (MRA) concrete, Treated Mixed Recycled Aggregate (TMRA) concrete, and TMRA incorporating Olivine Sand (TMRAOS) concrete. The findings reveal that the incorporation of treated MRA and Olivine Sand significantly enhances the bond strength at the rebar-concrete interface, a critical factor for the durability and performance of concrete structures.

“Our research demonstrates that TMRAOS concrete not only improves mechanical strength but also exhibits superior bond performance,” said Basnett. “This makes it a viable and eco-friendly alternative to conventional concrete, with strong potential for sustainable infrastructure applications.”

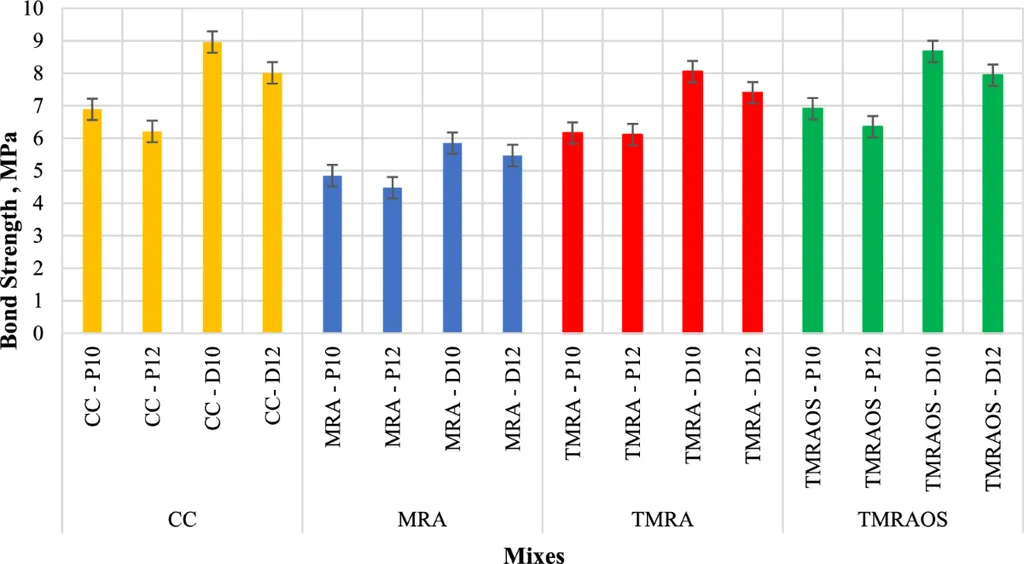

The experimental analyses, including compressive strength tests, pull-out tests, and microstructural evaluations using High-Resolution Scanning Electron Microscopy (HRSEM), showed that the TMRAOS mix exhibited improvements of 28.55% and 11.90% in mechanical strength compared to MRA and TMRA mixes, respectively. In terms of bond performance, the bond strength increased from 4.48 to 5.85 MPa in MRA to 6.11–8.05 MPa in TMRA, and further to 6.35–8.67 MPa in TMRAOS, with corresponding slip values of 2.48–4.36, 2.75–4.87, and 2.96–5.23 mm, respectively.

The study also highlighted improved stress distribution, reduced crack propagation, and enhanced bond-slip behaviour in the TMRAOS mix. Finite Element Modelling (FEM) further validated these findings, showing strong agreement between experimental and numerical results.

The implications of this research are significant for the construction industry, particularly in the energy sector where sustainable and durable materials are increasingly in demand. The use of recycled aggregates and alternative fillers not only reduces dependence on virgin raw materials but also minimizes construction and demolition waste, contributing to environmental sustainability.

As the industry continues to seek innovative solutions to meet sustainability goals, the findings from Basnett’s research offer a compelling case for the adoption of TMRAOS concrete. This eco-friendly and structurally efficient alternative could pave the way for more sustainable infrastructure projects, reducing the environmental footprint of construction activities while maintaining high performance standards.

“This research is a step forward in our journey towards sustainable construction,” said Basnett. “It showcases the potential of recycled materials and alternative fillers in creating high-performance concrete that meets the demands of modern infrastructure.”

As the construction industry continues to evolve, the integration of sustainable materials like TMRAOS concrete could become a cornerstone of future developments, shaping the way we build and interact with our environment. The study’s findings, published in *Scientific Reports*, provide a robust foundation for further exploration and application of these innovative materials in the quest for a more sustainable future.