In the quest for sustainable construction materials, researchers have turned to an unlikely duo: volcanic ash and magnetized water. A recent study published in the journal *Scientific Reports* (translated as *Nature Research Journal*), led by Mostafa M. Keshta from the Structural Engineering Department at Mansoura University, explores the potential of these materials to revolutionize the production of high-strength, fiber-reinforced mortars.

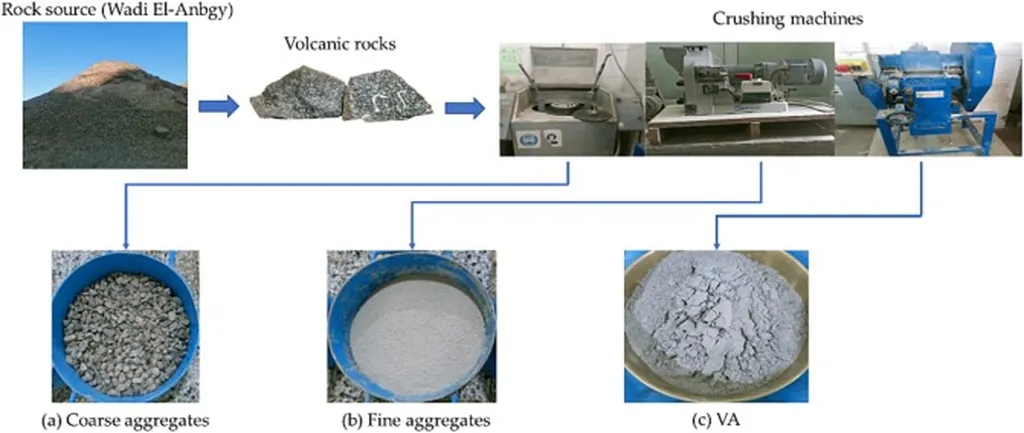

The construction industry has long grappled with the environmental impact of high cement consumption, which contributes significantly to global carbon emissions. Keshta’s research offers a promising alternative by incorporating volcanic ash (VA) as a partial replacement for conventional components in high-strength fiber-reinforced cementitious mortar (HS-FRCM) and high-strength fiber-reinforced geopolymer mortar (HS-FRGM). “The use of volcanic ash not only reduces the reliance on cement but also enhances the workability of the mortar,” Keshta explains. “In our tests, we saw a remarkable improvement of up to 150% in workability for HS-FRCM.”

The study also introduced magnetized water (MW) as a sustainable mixing water alternative, replacing traditional tap water (TW). The results were striking: MW improved the workability of both HS-FRCM and HS-FRGM by up to 100%, and compressive strengths increased by as much as 15%. “The microstructural analyses revealed a denser structure with a stronger bond between the fibers and the matrix, as well as fewer microcracks and pores,” Keshta notes. “This suggests that magnetized water could play a crucial role in enhancing the durability and strength of construction materials.”

The research also examined the impact of different curing conditions—tap water, seawater, air, and sunlight—on the mechanical performance and durability of the mortars. The highest compressive strength was recorded when the mortars were cured in tap water, highlighting the importance of curing methods in achieving optimal material properties.

The implications of this research for the construction and energy sectors are profound. By reducing the reliance on cement and incorporating sustainable materials like volcanic ash and magnetized water, the industry can significantly lower its carbon footprint. “This approach not only benefits the environment but also offers economic advantages by utilizing readily available and cost-effective materials,” Keshta says.

As the construction industry continues to seek innovative solutions to sustainability challenges, Keshta’s research provides a compelling case for the adoption of volcanic ash and magnetized water in the production of high-strength, fiber-reinforced mortars. The study, published in *Scientific Reports*, offers a glimpse into the future of sustainable construction, where environmental responsibility and economic efficiency go hand in hand.