In the heart of Bangkok, a groundbreaking study led by Tidarut Jirawattanasomkul from Chulalongkorn University is revolutionizing the way we monitor and maintain critical infrastructure. Jirawattanasomkul, affiliated with the Center of Excellence in Innovative Construction Materials and GreenTech Nexus, has developed a digital twin (DT) and structural health monitoring (SHM) system for balanced cantilever bridges, a type of bridge commonly used in the energy sector for crossing rivers and valleys.

The study, published in the journal “Resilient Cities and Structures” (translated as “เมืองและโครงสร้างที่มีความมั่นคง” in Thai), combines advanced measurement techniques to enhance the accuracy of structural health monitoring. “This is not just about collecting data; it’s about creating a living, breathing digital replica of the bridge that can predict its behavior under various conditions,” Jirawattanasomkul explained.

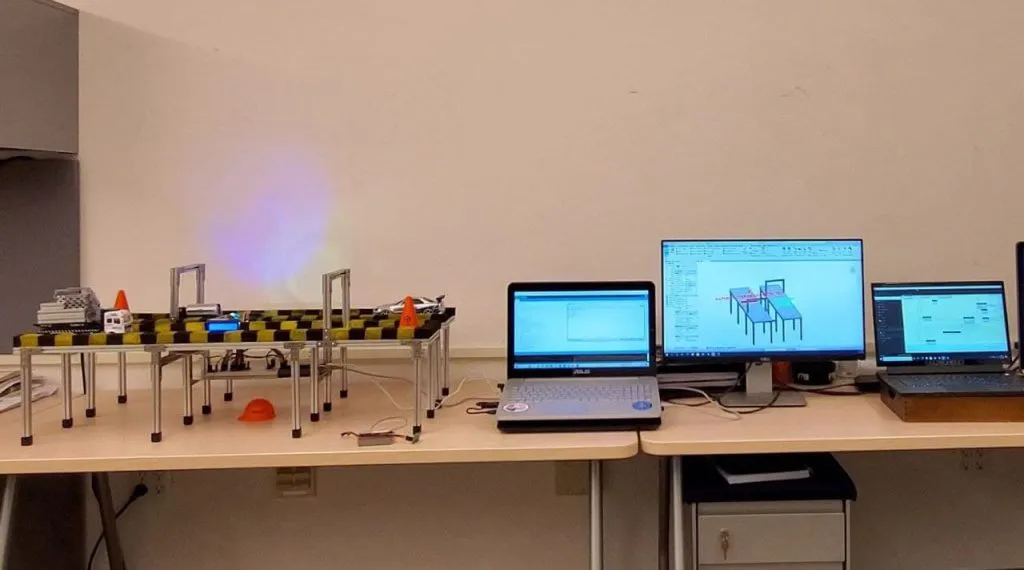

The research utilizes accelerometers and piezo-resistive strain gauges to capture low-magnitude dynamic strains during operational vibrations. 3D-LiDAR scanning and Ultrasonic Pulse Velocity (UPV) tests were employed to capture the bridge’s as-is geometry and modulus of elasticity. The resulting detailed 3D point cloud model revealed the structure’s true state, highlighting discrepancies between the as-designed and as-built conditions.

Dynamic properties, including modal frequencies and shapes, were extracted from the strain and acceleration measurements, providing critical insights into the bridge’s structural behavior. The neutral axis depth, indicating stress distribution and potential damage, was accurately determined. “The neutral axis depth is a crucial parameter. It tells us where the bridge is bearing the most stress and where potential damage might occur,” Jirawattanasomkul noted.

The study found good agreement between vibration measurement data and the as-is model results, validating the reliability of the digital twin model. Dynamic strain patterns and neutral axis parameters showed strong correlation with model predictions, serving as sensitive indicators of local damage. “This correlation is key. It means our digital twin is not just a static model but a dynamic tool that can help us predict and prevent failures,” Jirawattanasomkul added.

The baseline digital twin model and measurement results establish a foundation for future bridge inspections and investigations. This research demonstrates the effectiveness of combining digital twin technology with field measurements for real-time monitoring and predictive maintenance, ensuring the sustainability and safety of the bridge infrastructure.

The implications for the energy sector are significant. Balanced cantilever bridges are often used in energy projects, such as hydroelectric dams and pipelines, where structural integrity is paramount. Real-time monitoring and predictive maintenance can prevent catastrophic failures, reduce downtime, and save millions in repair costs.

As the energy sector continues to expand and infrastructure ages, the need for advanced monitoring systems becomes increasingly critical. Jirawattanasomkul’s research offers a promising solution, paving the way for smarter, safer, and more resilient infrastructure. “This is just the beginning,” Jirawattanasomkul said. “The potential applications of digital twin technology in the energy sector are vast and exciting.”