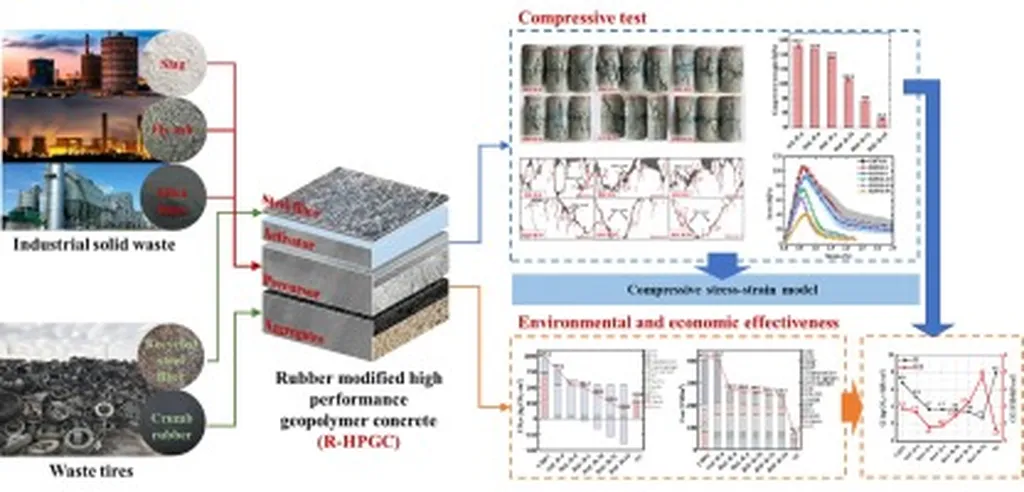

In the quest for sustainable construction materials, a groundbreaking review published in the journal *Advanced Materials Science Reviews* (formerly known as ‘Reviews on Advanced Materials Science’) sheds light on the promising potential of ultra-high-performance geopolymer concrete (UHPGC). This innovative material, developed by lead author Alshaeer Honin from the Department of Civil Engineering at Monash University Malaysia, offers a dual approach with both rubberized and non-rubberized formulations, addressing critical environmental and performance challenges in the construction sector.

Honin’s research delves into the unique properties of UHPGC, highlighting its rapid setting times, improved workability, and reduced shrinkage. The review emphasizes the material’s superior compressive, tensile, and flexural strengths, as well as enhanced energy absorption, ductility, fracture energy, and crack resistance. These characteristics make UHPGC an ideal candidate for high-stress environments, offering a sustainable alternative to conventional concrete.

One of the most intriguing aspects of this research is the incorporation of recycled rubber particles into UHPGC. “The addition of rubber particles significantly enhances the ductility, toughness, and energy absorption of the material,” Honin explains. “This makes it particularly suitable for high-performance applications where resilience is crucial.” However, the inclusion of rubber does come with a trade-off, as it can compromise compressive strength due to inadequate interfacial adhesion. Honin suggests that enhancements in surface treatment and the optimization of composite formulations can effectively overcome these challenges.

The review also explores the benefits of adding steel and polypropylene fibers to UHPGC, which enhance flexural toughness and fracture energy. This combination of materials not only improves mechanical integrity but also capitalizes on the elasticity of rubber, making it a versatile option for various construction needs.

The commercial implications for the energy sector are substantial. As the demand for sustainable and high-performance materials grows, UHPGC presents a viable solution for constructing energy-efficient buildings and infrastructure. Its enhanced durability and resilience can lead to longer-lasting structures, reducing maintenance costs and environmental impact.

Honin’s research underscores the need for ongoing investigation into microstructural optimization and long-term performance to fully harness the sustainability and functionality of UHPGC. As the construction industry continues to evolve, this innovative material could play a pivotal role in shaping a more sustainable future.

In the words of Honin, “The integration of geopolymer binders and recycled rubber particles offers a novel approach to enhancing both mechanical and environmental performance. This review provides a comprehensive analysis of UHPGC, guiding future research and policy in the construction industry.” With its potential to revolutionize sustainable construction, UHPGC is poised to make a significant impact on the energy sector and beyond.