In a groundbreaking development poised to revolutionize the construction and manufacturing industries, researchers have introduced a novel approach to additive manufacturing that promises to enhance efficiency and precision in multi-material 3D printing. This innovation, dubbed Continuous Multi-Material Additive Manufacturing (CMAM), is the brainchild of Jiawei Sun and his team at the Key Laboratory of Green Printing, Institute of Chemistry, Chinese Academy of Sciences in Beijing.

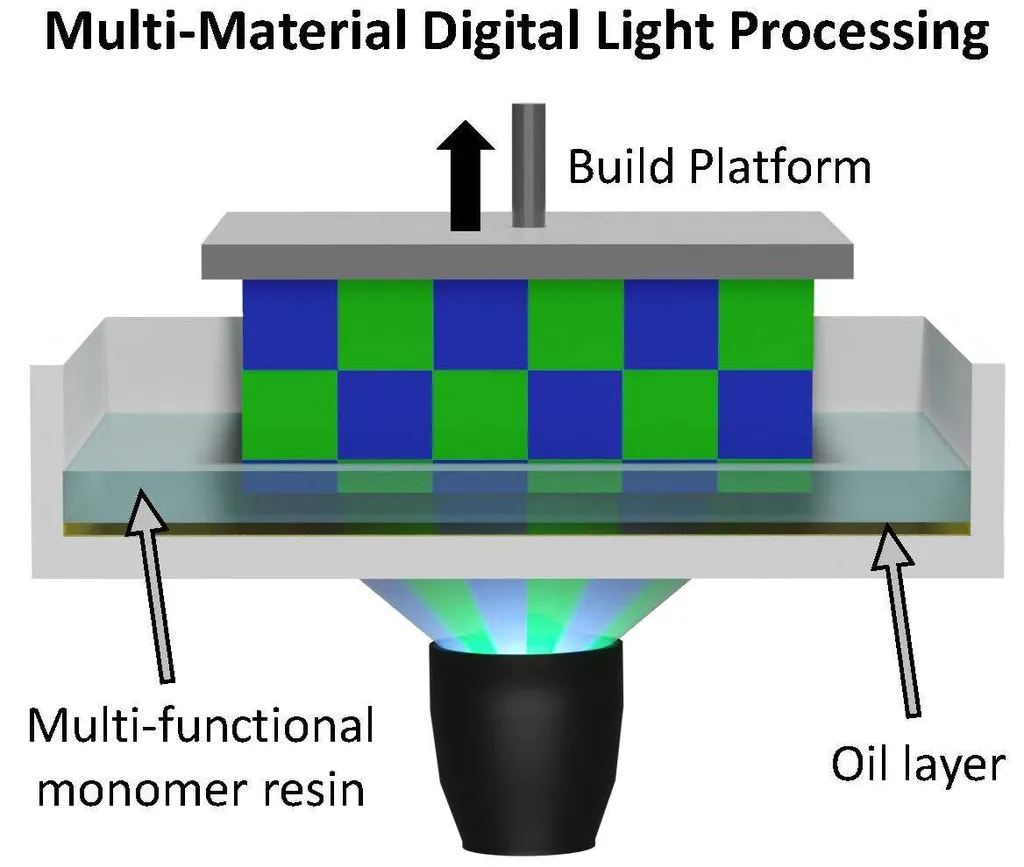

Traditional additive manufacturing techniques often face challenges when it comes to constructing complex 3D structures with multiple materials. The process typically requires switching vats, which disrupts the continuity of the construction. “Achieving simultaneous multi-material construction within a single layer and enabling continuous multi-material construction has been a substantial challenge,” explains Sun. His team’s solution integrates extruding multi-liquid phases into a droplet-based 3D printing system, enabling both 2D patterning of multi-liquid materials and their real-time curing, along with continuous resin replenishment.

The implications for the energy sector are profound. The ability to create complex, multi-material structures with precision could lead to advancements in the design and manufacturing of components for renewable energy technologies, such as wind turbines and solar panels. “This approach guarantees a highly efficient and sustainable method for multi-material 3D fabrication,” Sun notes, highlighting the potential for reduced waste and improved performance in energy-related applications.

One of the standout features of CMAM is its ability to control extrusion parameters layer by layer, allowing for precise material distribution. This level of control can be extended to applications in 3D structure-based anti-counterfeiting and soft robotics, opening up new avenues for innovation in these fields. Additionally, the technique allows for the adjustment of printing speed and resin viscosity to control interfacial fusion, enhancing mechanical adhesion without compromising boundary precision.

The research, published in the journal ‘Research’ (translated from Chinese as ‘Research’), represents a significant leap forward in additive manufacturing technology. As the industry continues to evolve, the ability to create complex, multi-material structures with high precision and efficiency will be crucial. Sun’s work not only addresses current challenges but also paves the way for future developments in the field.

The commercial impacts of this research are vast. By enabling more efficient and precise manufacturing processes, CMAM could reduce production costs and improve the performance of a wide range of products. This could lead to significant advancements in various industries, including energy, healthcare, and aerospace. As the technology continues to develop, it is likely that we will see even more innovative applications emerge, further solidifying the role of additive manufacturing in the future of construction and design.