In the heart of China, researchers at Henan Polytechnic University have been cooking up a storm—not in the kitchen, but in the lab. Jian Gong, a professor at the School of Civil Engineering, and his team have been working on a novel concrete composite that could shake up the construction and energy sectors. Their research, published in *Results in Engineering* (translated as “Engineering Results”), offers a promising avenue for sustainable construction materials engineering.

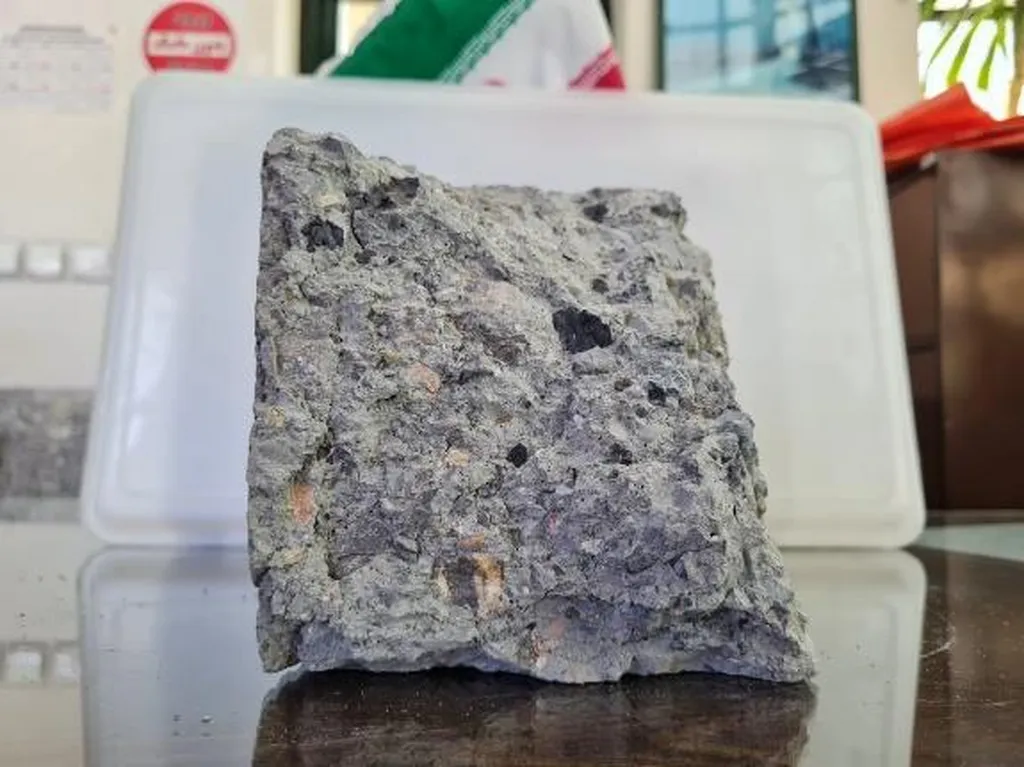

The team’s innovation lies in the integration of industrial slag—a waste product from steel manufacturing—into magnesium oxychloride cement (MOC). This isn’t just about recycling; it’s about creating a material that’s stronger, more durable, and more cost-effective. “We’re not just trying to reduce waste,” Gong explains. “We’re aiming to create a material that outperforms traditional concrete in key areas.”

The secret ingredient? Phosphoric acid. By adding a small amount—just 2% by mass—they’ve significantly boosted the material’s strength and water resistance. “It’s like adding a pinch of salt to a recipe,” Gong says. “A little goes a long way.”

To test the material’s dynamic mechanical properties, the team used an electromagnetically-driven Split Hopkinson Pressure Bar (SHPB) apparatus. Think of it as a high-speed impact test that helps understand how materials behave under extreme conditions, like those found in energy infrastructure.

The results were impressive. The modified material showed enhanced energy dissipation capacity and improved resistance to external deformation. This means it could be particularly useful in the energy sector, where materials often face harsh conditions.

But the team didn’t stop there. They also proposed a dynamic damage constitutive model based on the Zertel-Willis-Taylor (ZWT) framework, tailored specifically for this composite. This model could help predict how the material will behave under different conditions, making it easier to design and build structures that use it.

So, what does this mean for the future? Gong believes this research could pave the way for more sustainable and efficient construction materials. “We’re not just creating a new material,” he says. “We’re opening up new possibilities for how we build and how we use resources.”

In the energy sector, this could mean more durable wind turbine foundations, stronger offshore platforms, or more resilient power plants. It’s a step towards a future where waste isn’t just discarded—it’s transformed into something stronger and more useful.

As Gong and his team continue their work, one thing is clear: the future of construction is looking stronger, more sustainable, and more innovative than ever before. And it all started with a simple idea—turning waste into something extraordinary.