In a groundbreaking study that marries sustainability with practicality, researchers have discovered a novel way to repurpose industrial polymer roof waste into durable cement cobblestones, potentially reshaping the construction and energy sectors. The research, led by Á. Alonso from the Department of Architectural Constructions and I.C.T. at Burgos University in Spain, explores the use of polyurethane, polyester, and fiberglass-based roofing waste from the automotive industry as a partial replacement for natural fine aggregates in cement-based mortar paving blocks.

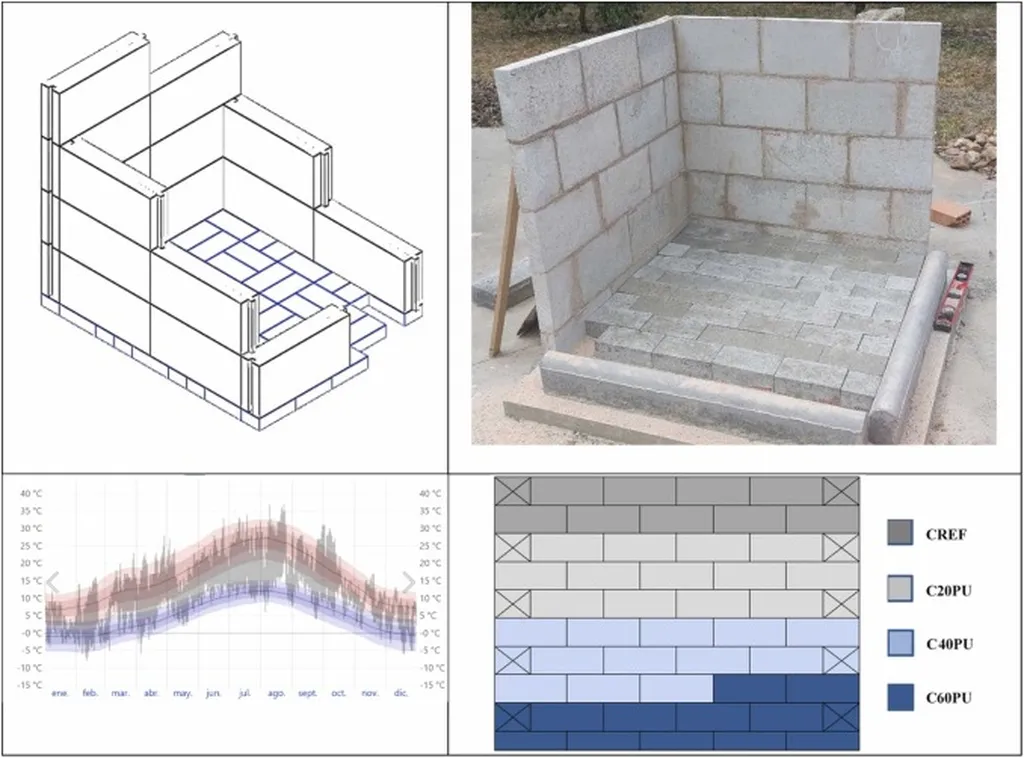

The study, published in *Case Studies in Construction Materials* (translated to English as *Case Studies in Construction Materials*), reveals that these innovative paving elements can be manufactured with replacement levels of 20%, 40%, and 60% by volume. The results are promising: all mixtures met the minimum splitting tensile strength requirement of 3.60 MPa, with the 40% replacement level achieving a peak improvement of 9.3% compared to traditional materials. “This demonstrates that we can significantly reduce our reliance on natural resources without sacrificing performance,” Alonso explains.

One of the most compelling findings is the reduction in density, which decreased by up to 300 kg/m³. This not only improves handling but also reduces transportation impacts, a crucial consideration for the energy sector where logistics and carbon footprints are increasingly under scrutiny. “Lighter materials mean lower transportation costs and reduced emissions, which aligns with the growing demand for sustainable urban infrastructure,” Alonso adds.

Durability tests, including salt crystallization, freeze–thaw cycles, and outdoor exposure, confirmed the suitability of these materials for exterior paving applications. This research offers a technically viable and environmentally beneficial alternative for sustainable urban infrastructure, potentially influencing future developments in the field.

The implications for the energy sector are substantial. As the push for circular economy practices gains momentum, this study provides a blueprint for other industries to follow. By repurposing waste materials, companies can reduce their environmental impact while also cutting costs. “This is a win-win situation,” Alonso notes. “It’s not just about being eco-friendly; it’s about creating a more efficient and cost-effective supply chain.”

As the construction industry continues to evolve, this research could pave the way for more innovative and sustainable practices. The study not only highlights the potential of industrial polymer waste but also sets a precedent for future research in the field. With the growing emphasis on sustainability, this discovery could be a game-changer, offering a glimpse into a future where waste is not just discarded but transformed into valuable resources.