In the quest to reduce the construction industry’s environmental impact, researchers have turned to innovative material solutions, and a recent study published in the journal “Reviews on Advanced Materials Science” (which translates to “Reviews on Advanced Materials Science”) offers promising insights. The study, led by Moolchandani Karan from the Department of Civil Engineering at Maulana Azad National Institute of Technology in Bhopal, India, explores the potential of sustainable concrete incorporating crumb rubber (CR) and supplementary cementitious materials (SCMs).

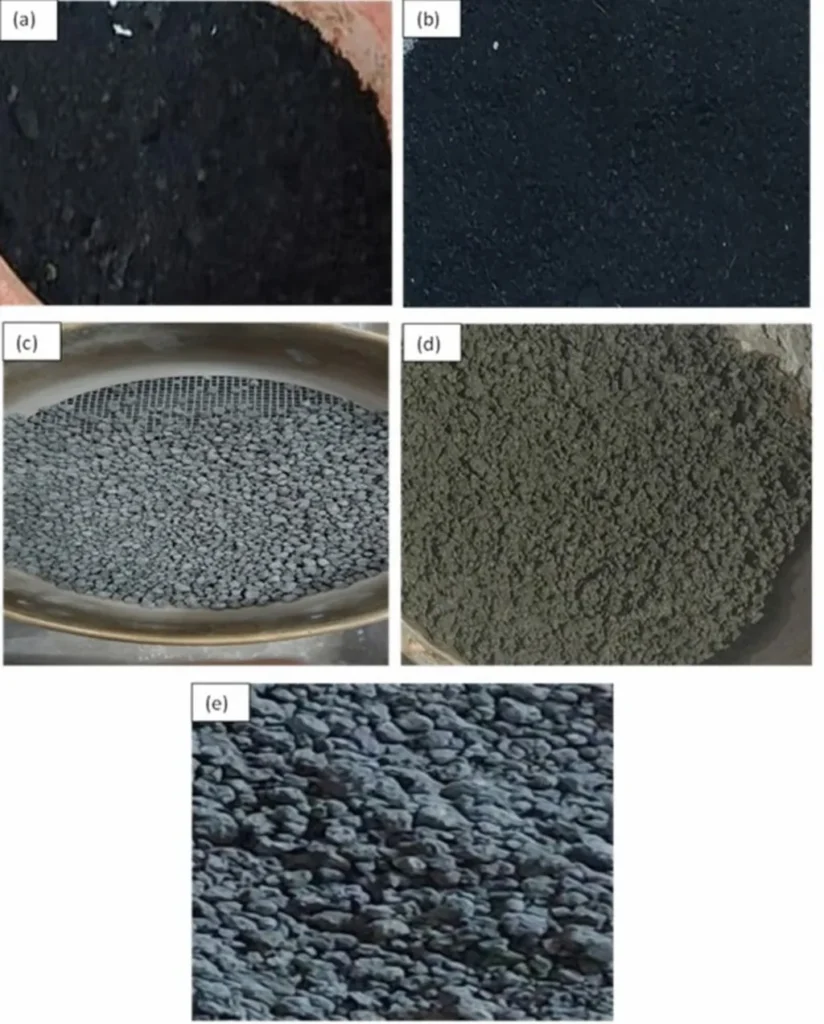

The research focuses on the morphological and microstructural characteristics of concrete that includes crumb rubber, fly ash (FA), silica fume (SF), and marble slurry powder (MSP). By preparing fifteen hybrid mix designs, the team aimed to understand how these materials interact at a microscopic level to enhance the concrete’s properties.

“Our goal was to investigate the phase composition, hydration products, and interface morphology of these sustainable concretes,” Moolchandani Karan explained. The team employed advanced techniques such as X-ray diffraction, Fourier transform infrared spectroscopy, field emission scanning electron microscopy, and energy dispersive X-ray spectroscopy to delve into the intricate details of the concrete’s internal structure.

The findings revealed that the optimal mix, containing 5% SF, 10% MSP, and 15% FA, exhibited a significant reduction in portlandite (a byproduct of cement hydration) by approximately 22–25%. This reduction indicates strong pozzolanic interaction, a chemical process that enhances the concrete’s strength and durability. Additionally, the mix showed enhanced amorphous C–S–H gel formation, which is crucial for the concrete’s binding and structural properties.

Marble slurry powder played a pivotal role in refining the pores within the concrete, leading to improved interfacial bonding. Despite its non-reactive nature, crumb rubber contributed to the concrete’s ductility and energy absorption potential, making it more resilient to impacts and vibrations.

Elemental mapping confirmed the uniform distribution of calcium and silicon, supporting improved hydration product formation and overall microstructural integrity. These results highlight the synergistic effect of crumb rubber and supplementary cementitious materials in enhancing concrete’s internal structure.

The implications of this research are significant for the energy sector, particularly in the construction of energy-efficient buildings and infrastructure. By reducing the reliance on Portland cement, a major contributor to global CO2 emissions, these sustainable concretes offer a greener alternative without compromising on performance.

“Our findings contribute to the ongoing efforts to reduce the construction industry’s carbon footprint,” Moolchandani Karan stated. “The integration of waste materials like crumb rubber and industrial byproducts such as fly ash and marble slurry powder not only enhances the concrete’s properties but also promotes a waste-to-resource approach.”

As the construction industry continues to seek sustainable solutions, this research paves the way for future developments in the field of sustainable concrete. By leveraging advanced materials and innovative techniques, the industry can move towards a more environmentally friendly and resilient future.

The study, titled “Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs,” was published in the journal “Reviews on Advanced Materials Science,” offering valuable insights for researchers, engineers, and industry professionals alike.