In the quest for sustainable and resilient construction materials, a recent study has shed light on the promising role of polypropylene fiber (PPF) in enhancing the performance of lightweight concrete. Led by Mohamed Abdeliazim Mustafa from the Department of Civil Engineering at Prince Sattam bin Abdulaziz University in Saudi Arabia, the research published in ‘Reviews on Advanced Materials Science’ (or ‘Review of Advanced Materials Science’ in English) offers valuable insights into the potential of PPF as a reinforcement material, with significant implications for the energy sector and beyond.

Lightweight concrete has long been favored for its reduced weight and improved thermal insulation properties, making it an attractive option for energy-efficient buildings. However, its relatively lower mechanical performance has posed challenges for structural applications. Mustafa’s study delves into the integration of PPF into lightweight concrete mixtures, demonstrating notable improvements in compressive strength, flexural strength, and ductility.

“The incorporation of polypropylene fiber significantly enhances the toughness, crack resistance, and energy absorption capacity of lightweight concrete,” Mustafa explains. This enhanced performance is particularly relevant for structural applications where reduced weight and increased durability are crucial, such as in high-rise buildings and energy-efficient infrastructure.

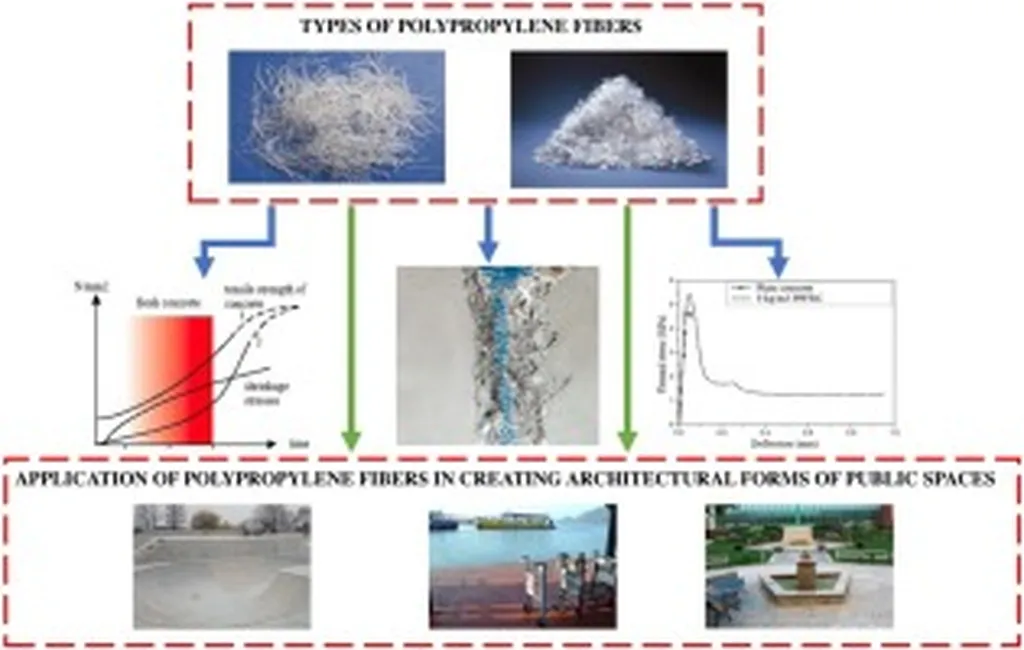

The study highlights that the benefits of PPF integration are closely tied to the type, dosage, and distribution of the fibers. Mustafa emphasizes the importance of careful mix design and optimization to achieve the desired mechanical properties. “The performance gains are closely related to the fiber type, dosage, and distribution,” he notes, underscoring the need for tailored approaches in mix design.

The research also addresses the effects of PPF on failure modes, stress–strain behavior, and crack propagation in lightweight concrete. By providing a comprehensive analysis of the chemical and physical characteristics of various PPF types, the study offers a nuanced understanding of their influence on concrete behavior.

For the energy sector, the implications are substantial. Lightweight concrete reinforced with PPF could contribute to more energy-efficient buildings by reducing the overall weight of structures and improving their thermal performance. This, in turn, could lead to lower energy consumption for heating and cooling, aligning with global sustainability goals.

Moreover, the enhanced durability and crack resistance of PPF-reinforced lightweight concrete could extend the lifespan of structures, reducing maintenance costs and minimizing the environmental impact associated with repairs and replacements.

As the construction industry continues to prioritize sustainable and durable materials, Mustafa’s research serves as a foundation for future developments in fiber-reinforced concrete. By addressing limitations in previous studies and offering valuable insights, the study paves the way for broader adoption of PPF-reinforced lightweight concrete in environmentally conscious construction projects.

In the words of Mustafa, “This research contributes valuable insights for the development of durable, sustainable building materials.” As the industry moves towards more sustainable practices, the integration of PPF in lightweight concrete could play a pivotal role in shaping the future of construction, particularly in the energy sector.