In a significant stride towards sustainable construction, researchers have unveiled promising findings on the compressive strength of geopolymers reinforced with recycled carbon fibres, with implications that could reshape underwater and additive manufacturing applications in the energy sector. The study, led by Meike Denker from the Institute for Machine Elements, Engineering Design and Manufacturing at Technische Universität Bergakademie Freiberg in Germany, explores the potential of these innovative materials to outperform traditional Portland cement in specialized environments.

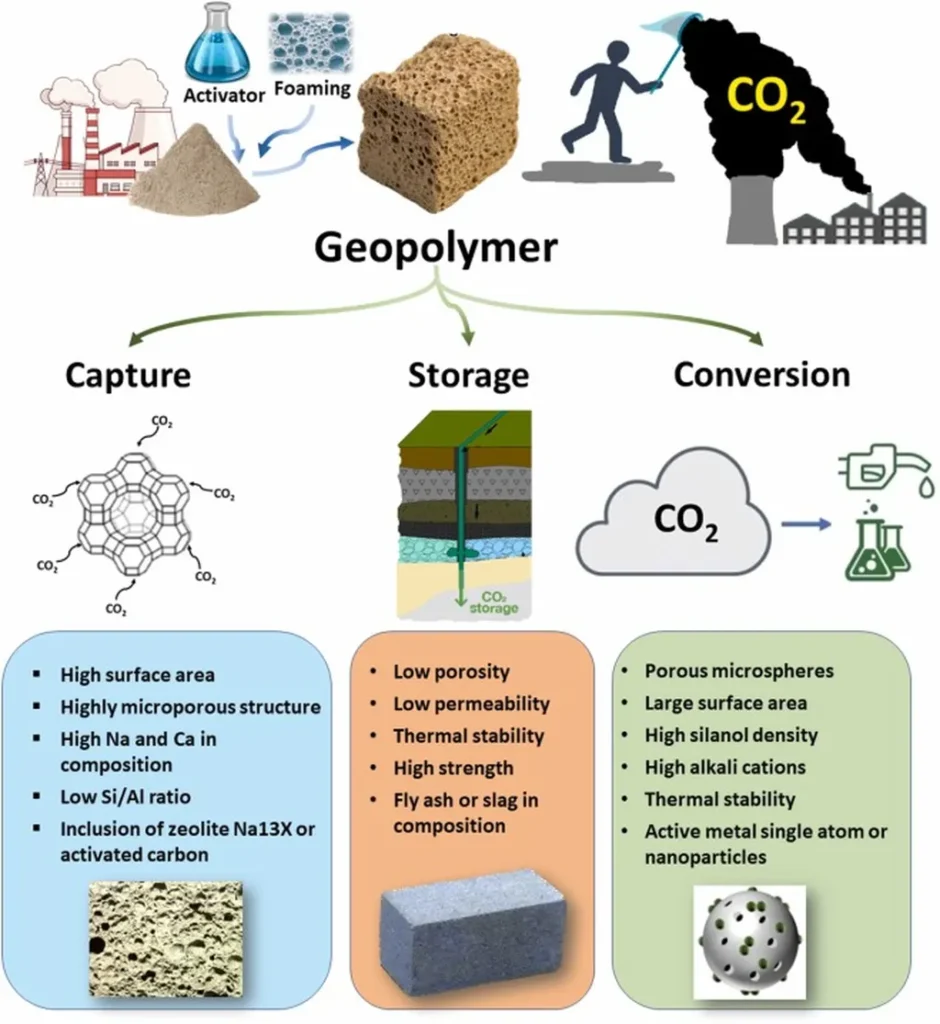

Geopolymers (GPs), known for their eco-friendly credentials and robust properties, are synthesized from materials like metakaolin and fly ash. They offer high hardness, weathering resistance, and thermal stability, making them ideal for additive manufacturing (AM) and underwater applications. Denker’s research delves into the compressive strength of metakaolin-based GPs reinforced with recycled carbon fibres, comparing their performance in various water environments over time.

The study produced samples through mould casting in air, manual underwater extrusion, and AM via material extrusion with chemical reaction bonding (MEX-CRB) in air. The results were enlightening. Mould-cast specimens in air reached an impressive compressive strength of approximately 50 MPa, while MEX-CRB samples achieved around 20 MPa. After three months in salt water, mould-cast samples retained about 30 MPa, whereas printed ones remained below 20 MPa. Manually printed underwater samples showed a notable increase from approximately 8 MPa at casting to 14–15 MPa by week 4 before stabilizing.

Denker emphasized the importance of these findings, stating, “The microstructural observations revealed that crack-bridging by fibres significantly enhances the material’s strength. The random orientation of fibres in cast samples improved isotropic strength, while fibre alignment and higher porosity in printed samples limited performance.”

The implications for the energy sector are substantial. Geopolymers’ ability to encapsulate hazardous substances and stabilize corroding shipwrecks offers a sustainable solution for underwater construction and hazard prevention. “This research underscores the environmentally friendly potential of GPs in reducing environmental risks and developing sustainable methods for underwater construction and hazard prevention,” Denker added.

The study, published in ‘Frontiers in Built Environment’ (translated to English as ‘Frontiers in the Built Environment’), highlights the potential for geopolymers to revolutionize construction practices. As the energy sector increasingly seeks sustainable and durable materials, the findings from Denker’s research could pave the way for innovative applications in underwater and additive manufacturing, ultimately contributing to a greener and more resilient built environment.

The research not only advances our understanding of geopolymer performance but also opens new avenues for commercial applications in the energy sector. As the industry continues to evolve, the insights gained from this study could shape future developments, driving the adoption of more sustainable and efficient construction methods.