The construction industry is on the cusp of a drilling revolution, and Hybrid Impact Technology (HIT) is leading the charge. This innovative approach to down-the-hole (DTH) drilling is transforming operations across mining, construction, and energy sectors, promising to redefine efficiency and performance standards. But what does this mean for the future of construction, and how might it reshape the industry’s approach to sustainability and productivity?

The traditional drilling landscape has long been dominated by pneumatic DTH and rotary systems, both of which have faced persistent challenges. “Both approaches experience substantial energy losses between the power source and the rock face,” according to industry reports from GeoDrilling International. These inefficiencies have plagued operators for decades, driving the search for more effective solutions. Enter HIT, a technology that replaces compressed air with hydraulic energy, creating a more direct and efficient power transfer pathway. This shift addresses long-standing challenges and opens new possibilities for applications where conventional systems struggle.

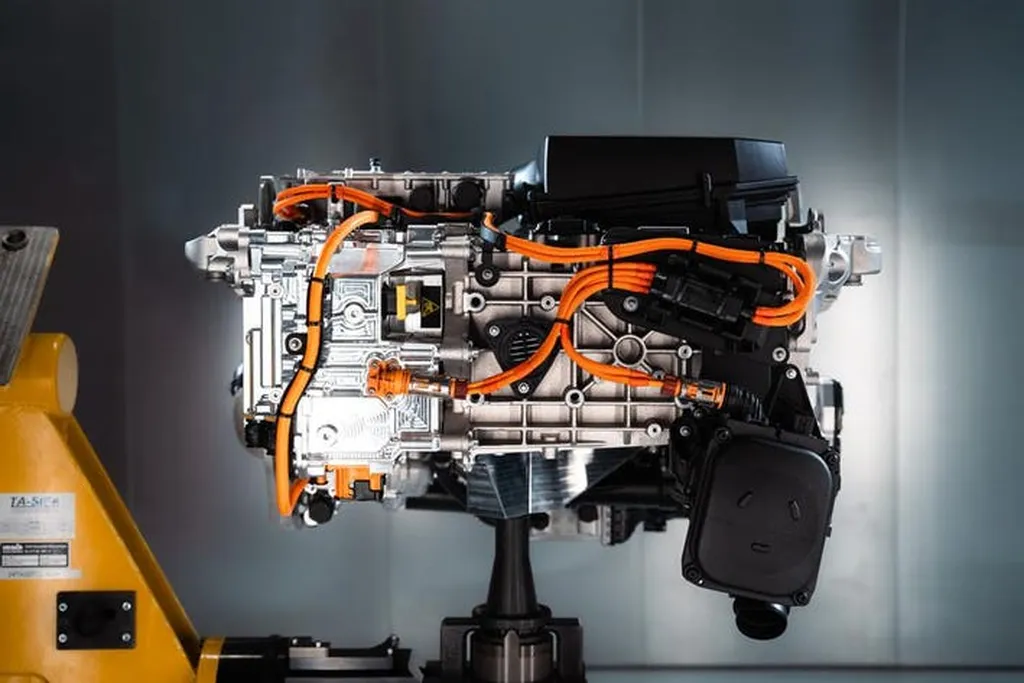

The core innovation of HIT lies in its energy transfer mechanism, which rethinks traditional drilling principles to overcome inherent inefficiencies. “The technology transfers power to the drilling bit more directly with substantially reduced energy loss compared to conventional systems,” explains industry experts. This direct hydraulic power transmission reduces energy losses, friction, and heat generation, resulting in more consistent power delivery and optimized energy utilization.

The performance advantages of HIT are substantial. Compared to traditional methods, HIT offers comparable or superior penetration rates, more precise control over impact force and frequency, enhanced operational stability, reduced vibration, and more consistent performance across varying geological conditions. These benefits are particularly valuable in applications requiring precision, reliability, and efficiency.

The implementation of HIT delivers multiple advantages that address critical challenges in drilling operations. Operationally, HIT offers significant improvements in efficiency, with hydraulic systems demonstrating 30-50% lower energy requirements compared to pneumatic alternatives. This translates to decreased fuel requirements, reduced maintenance needs, extended equipment lifespan, and enhanced drilling rates. Environmentally, HIT contributes to sustainability goals by decreasing carbon emissions, reducing noise and dust pollution, and minimizing the operational footprint.

Economically, HIT presents a compelling case. While initial investment costs may be higher, the total cost of ownership analysis typically demonstrates significant benefits, particularly for high-utilization operations. Reduced operational expenses, lower maintenance costs, potential productivity increases, and competitive differentiation through advanced technology adoption all contribute to a strong economic argument for HIT.

When compared to traditional drilling technologies, HIT’s advantages become evident. Pneumatic DTH systems, for instance, suffer from higher energy losses, increased operational costs, and greater environmental impact. Rotary drilling, while effective in softer formations, lacks the versatility and efficiency of HIT in harder materials. HIT’s ability to maintain consistent performance across varying conditions and its reduced environmental footprint position it as a forward-looking technology aligned with sustainable practices.

The applications benefiting most from HIT are those where efficiency and performance are critical. In the construction industry, this technology can enhance productivity, reduce costs, and minimize environmental impact. As the sector increasingly prioritizes sustainability, HIT offers a promising solution that aligns with broader industry goals.

The adoption of HIT is not just about improving drilling operations; it’s about reimagining the future of construction. By embracing this technology, the industry can achieve greater efficiency, reduce its environmental footprint, and drive innovation. As HIT continues to evolve, it has the potential to reshape the construction landscape, making it more sustainable, productive, and resilient. The drilling revolution is here, and it’s time for the construction industry to seize the opportunity.