In a significant stride towards sustainable housing, researchers have developed an optimized industrialized wall system that promises to reduce energy demand, carbon footprint, and construction costs. This innovative system, detailed in a study published in *Case Studies in Thermal Engineering* (translated as *Case Studies in Thermal Engineering*), could reshape the future of residential construction, particularly in cold climates.

The study, led by Carlos Rojas-Herrera from the Facultad de Arquitectura, Construcción y Medio Ambiente at Universidad Autónoma de Chile, focuses on a modular wall system that integrates sustainability principles and alternative insulation materials. The research addresses the urgent need for energy-efficient and low-impact housing solutions, especially in regions with pressing social housing demands.

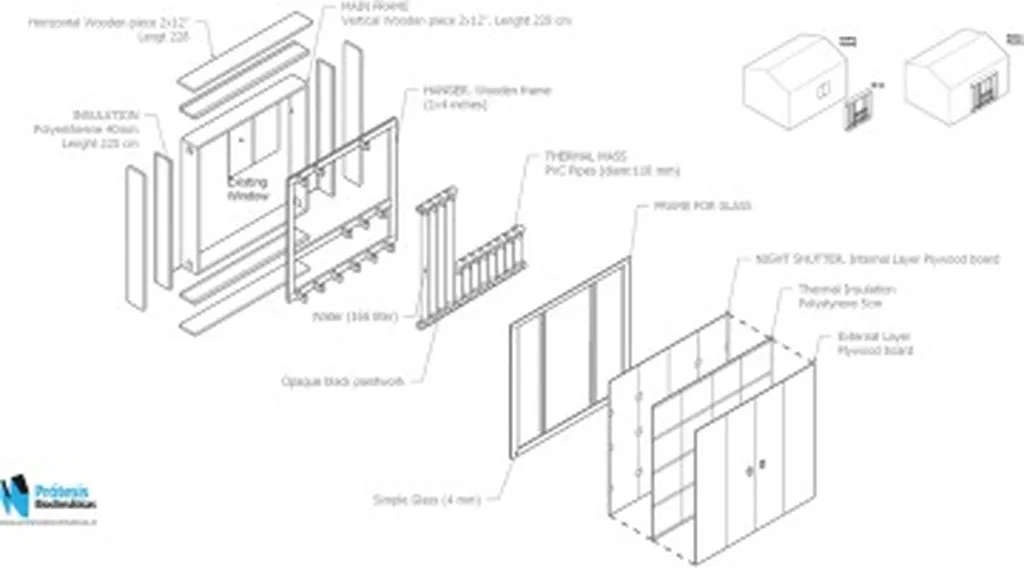

The construction sector is a major contributor to global energy consumption and greenhouse gas emissions. Concurrently, the housing deficit has driven the adoption of industrialized construction systems in residential projects. This study presents a multi-objective optimization of a modular wall system that integrates sustainability principles and alternative insulation materials to reduce energy demand for heating and cooling, carbon footprint, construction costs, and construction time. A workflow was developed, starting with the definition of a case study, including its location and architectural configuration for a cold climate, followed by dynamic energy simulations and optimization using evolutionary algorithms. A total of 157 simulations were conducted with DesignBuilder and EnergyPlus, assessing combinations of insulation materials (sawdust, wheat straw, and glass wool) and panel thicknesses. The optimal configuration included plywood panels and wheat straw insulation. Compared to a traditional wall, this solution achieved an 11.12 % reduction in energy demand, a 1.80 % reduction in carbon footprint, and a 1.80 % reduction in cost, along with a construction speed up to eight times faster under controlled test conditions. Additionally, when considering a more realistic heat pump scenario (CoP = 3), the operational carbon footprint decreases by approximately 66 %, reinforcing the environmental potential of the proposed system. These results demonstrate the capacity of optimized industrialized systems to deliver energy-efficient, low-impact, and scalable housing solutions, particularly in cold climates with urgent social housing needs.

The research involved a comprehensive workflow, starting with the definition of a case study that included the location and architectural configuration for a cold climate. Dynamic energy simulations were conducted using DesignBuilder and EnergyPlus, assessing combinations of insulation materials such as sawdust, wheat straw, and glass wool, along with varying panel thicknesses. The optimal configuration identified in the study included plywood panels and wheat straw insulation.

The results are promising. The optimized wall system achieved an 11.12% reduction in energy demand, a 1.80% reduction in carbon footprint, and a 1.80% reduction in cost compared to traditional walls. Moreover, the construction time was up to eight times faster under controlled test conditions. When considering a more realistic heat pump scenario with a Coefficient of Performance (CoP) of 3, the operational carbon footprint decreased by approximately 66%, further reinforcing the environmental potential of the proposed system.

“These results demonstrate the capacity of optimized industrialized systems to deliver energy-efficient, low-impact, and scalable housing solutions, particularly in cold climates with urgent social housing needs,” said Rojas-Herrera.

The implications for the energy sector are substantial. As the demand for sustainable housing grows, the adoption of such optimized systems could significantly reduce the energy consumption and carbon emissions associated with residential buildings. This not only aligns with global sustainability goals but also offers a competitive edge for construction companies that prioritize energy efficiency and environmental impact.

The study’s findings highlight the potential for industrialized construction systems to address both environmental and social housing challenges. By integrating alternative insulation materials and optimizing design parameters, the proposed system offers a scalable solution that can be adapted to various climates and construction contexts.

As the construction industry continues to evolve, the adoption of such innovative technologies will be crucial in meeting the demands for sustainable and affordable housing. The research conducted by Rojas-Herrera and his team represents a significant step forward in this direction, offering a blueprint for future developments in the field.

In the words of Rojas-Herrera, “The capacity of optimized industrialized systems to deliver energy-efficient, low-impact, and scalable housing solutions is a game-changer for the construction sector.” This research not only provides a roadmap for reducing energy demand and carbon footprint but also underscores the importance of continuous innovation in the pursuit of sustainable development.