In the quest for sustainable construction materials, researchers have made a significant stride by enhancing the properties of recycled concrete powder (RCP) through an innovative mechanical-microwave combing method. This breakthrough, led by Henan Shi from the China Academy of Railway Sciences Corporation Limited and the State Key Laboratory of High Speed Railway Track System in Beijing, could revolutionize the way the construction industry approaches recycling and waste management.

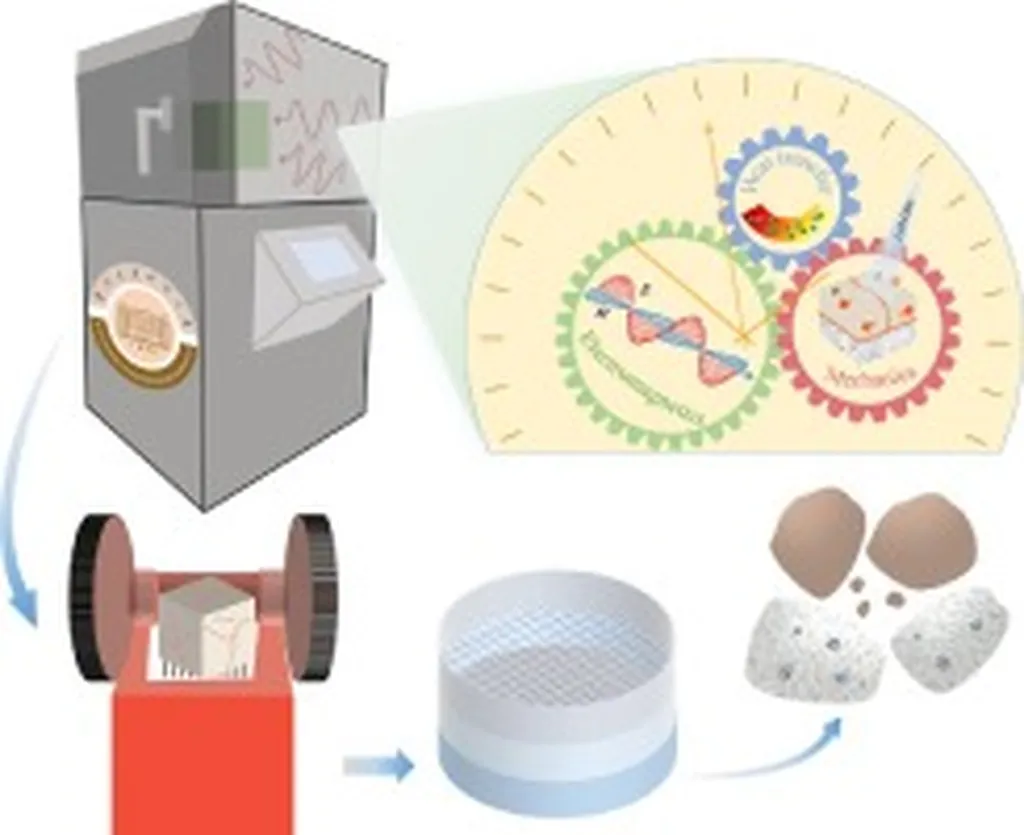

The study, published in the journal *Railway Engineering Research Institute* (translated from the original Chinese title), focuses on improving the reactivity of RCP, a byproduct of demolished concrete structures. Traditionally, RCP has seen limited use due to its low reactivity. However, the combined mechanical-microwave activation method has shown promising results in boosting its performance.

“By subjecting RCP to ball milling followed by microwave irradiation, we were able to significantly enhance its reactivity,” explains Shi. “This process not only reduces the particle size but also induces structural changes that make the material more reactive.”

The research team evaluated the mechanical properties, hydration products, and pore structure of mortar incorporating the activated RCP. The findings were impressive: the 28-day strength activity index (SAI) of RCP mortar improved from 65.7% to 82.2% under optimal activation conditions. This represents a substantial improvement over solely mechanical activation, which only achieved a 3.6–6.1% increase.

The enhanced reactivity of RCP translates into practical benefits for the construction industry. “Using activated RCP in cement-based materials reduces the demand for cement, which is a significant source of carbon emissions,” notes Shi. “This contributes to the industry’s green and low-carbon transition, making it a critical step towards more sustainable construction practices.”

The study also revealed that the combined activation method increased the chemically bound water content in the mortar, indicating improved hydration and a denser pore structure. This could lead to more durable and resilient construction materials, further enhancing their commercial appeal.

The implications of this research extend beyond the construction industry. As the world grapples with the challenges of climate change and resource depletion, the need for sustainable materials has never been greater. The mechanical-microwave activation method offers a promising solution, paving the way for the efficient utilization of recycled materials in various applications.

“This research provides valuable insights into the sustainable development of materials,” says Shi. “It opens up new possibilities for the construction industry to reduce its environmental impact while maintaining high standards of quality and performance.”

As the construction industry continues to evolve, the adoption of innovative technologies like the mechanical-microwave activation method could play a pivotal role in shaping its future. By embracing these advancements, the industry can move towards a more sustainable and environmentally friendly future, benefiting both the planet and the bottom line.