In the quest for smarter, more energy-efficient buildings, a team of researchers led by Muhammad Hanif Khan at Tianjin University has made a significant stride. Their work, published in the *Journal of Materials Research and Technology* (or, in English, the *Journal of Materials Science and Technology*), explores the potential of thermochromic fiber-reinforced composites to revolutionize the construction industry.

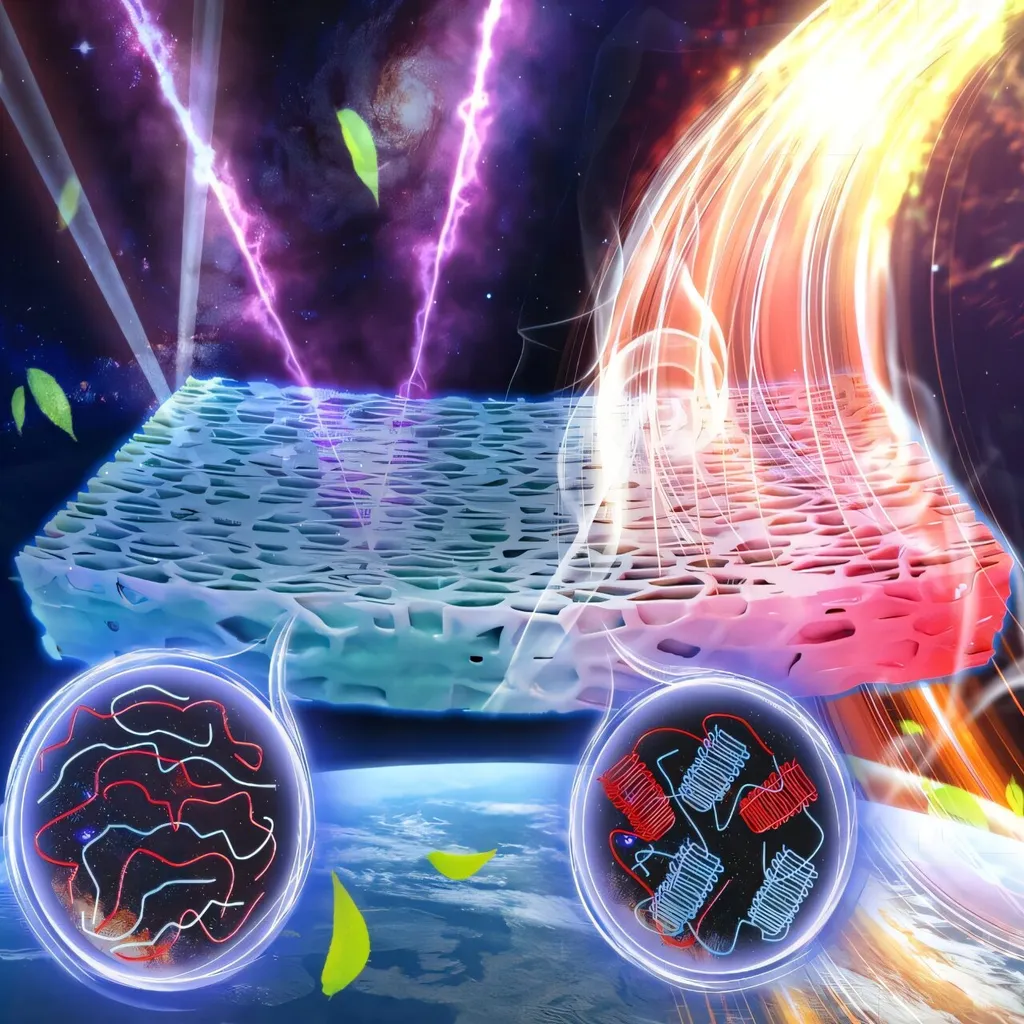

The study delves into the performance of cement and polymeric (epoxy and polyester) composites reinforced with thermochromic-functionalized fibers. These innovative materials are designed to passively regulate temperature by modulating solar radiation response in real time. “The idea is to create materials that can adapt to their environment, reducing energy consumption and improving indoor comfort,” Khan explains.

The researchers found that polymeric composites outperformed their cement counterparts in several key areas. Epoxy and polyester composites exhibited lower water absorption, higher compressive strength (ranging from 113 to 124.44 MPa), and superior flexural strength (26.15 to 28.56 MPa). In contrast, cement composites showed strengths of 45.0 to 49.10 MPa and 8.89 to 10.89 MPa, respectively.

Thermal evaluations revealed that the polymeric composites also demonstrated lower thermal conductivity and reduced surface temperatures, leading to improved indoor comfort. Energy simulations using EnergyPlus software showed that buildings incorporating these thermochromic fiber-based composite envelopes could reduce annual heating and cooling demands by 12.02 to 17.52 kWh/m² and cut carbon emissions by 4.16 to 6.19% compared to composites with uncoated fibers.

Microstructural analyses, including XRD, FTIR, and SEM, provided insights into the performance differences. The researchers discovered that thermochromic fibers slightly hindered cement hydration, weakening fiber-matrix bonding and increasing porosity, which reduced the overall strength of cement composites. Conversely, polymeric composites formed denser matrices with stronger fiber adhesion and improved structural integrity. The acrylic binder used in the polymeric composites also shielded the fibers from the alkalinity of the cement, while the lower alkalinity of the polymeric matrices preserved the stability of the thermochromic coating.

This research holds significant implications for the energy sector and the construction industry. As cities continue to grow and energy demands rise, the need for smart, energy-efficient building materials becomes increasingly critical. The development of thermochromic fiber-reinforced composites offers a promising solution, potentially reducing energy consumption and lowering greenhouse gas emissions.

Khan and his team’s findings suggest that polymeric thermochromic fiber composites could pave the way for more sustainable construction practices. “By integrating these advanced materials into building envelopes, we can create structures that are not only stronger and more durable but also more energy-efficient and environmentally friendly,” Khan states.

As the construction industry continues to evolve, the adoption of such innovative materials could lead to a paradigm shift in building design and construction. The research published in the *Journal of Materials Research and Technology* marks a significant step forward in this direction, offering a glimpse into the future of smart, sustainable buildings.