In a significant stride towards sustainable construction, researchers have unveiled a promising approach to reduce the cement industry’s substantial carbon footprint. The study, led by Arti Chouksey from the Department of Civil Engineering at Deenbandhu Chhotu Ram University of Science and Technology Murthal and Delhi Technological University, explores the partial replacement of Ordinary Portland Cement with lime sludge (LS) and metakaolin (MK) to create eco-efficient concrete composites. This research, published in AIP Advances (which translates to “Advances in Applied Physics” in English), offers a compelling narrative for the energy and construction sectors, aligning with the United Nations’ Sustainable Development Goals (SDGs).

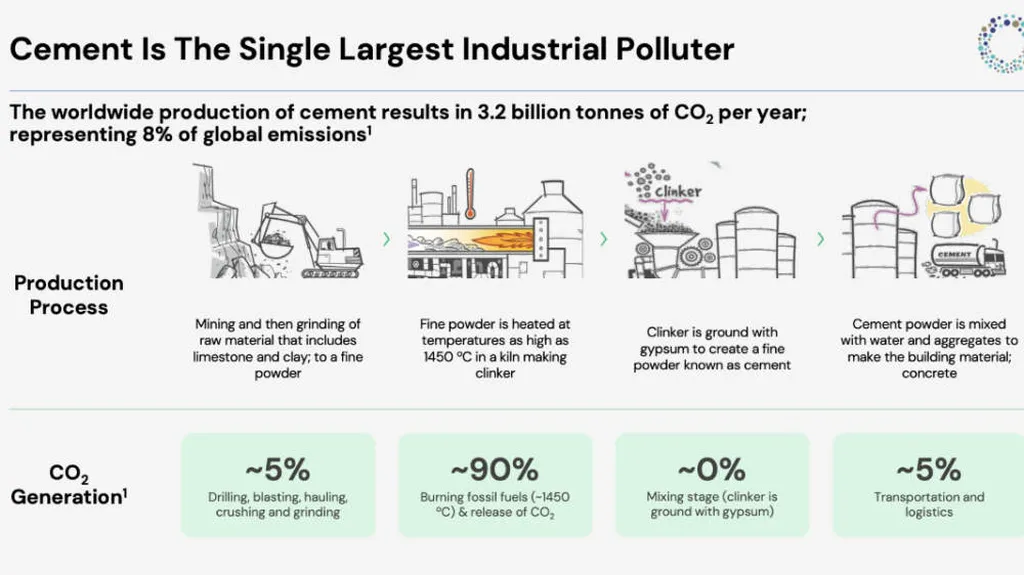

The cement industry is a major contributor to global CO2 emissions, accounting for nearly 8%. Chouksey and her team aimed to address this challenge by investigating the potential of LS, a calcium-rich by-product from paper manufacturing, and MK, a reactive pozzolana derived from calcined clay. Their goal was to develop sustainable concrete that supports the 3R principles—Reduce, Reuse, Recycle—and contributes to SDGs 9 (Industry, Innovation, and Infrastructure) and 11 (Sustainable Cities and Communities).

The research team designed 16 concrete mixes (M25 grade) with varying LS (0%–15%) and MK (0%–15%) replacement levels. The mix containing 10% LS and 10% MK (L10M10) demonstrated remarkable performance improvements. “The L10M10 mix showed a 22.8% increase in 28-day compressive strength and a 25.8% improvement at 90 days compared with the control,” Chouksey explained. Flexural and tensile strengths also saw notable enhancements, with increases of 13.2% and 12.5%, respectively.

Beyond strength, the L10M10 mix exhibited superior durability. Its density increased by over 10%, while water absorption decreased from 8% to 6.4%. Acid-induced mass loss also reduced from 10% to 8% after 12 weeks, indicating enhanced resistance to chemical degradation. Scanning electron microscopy analysis revealed a denser microstructure with refined C–S–H gel formation and minimal porosity, while energy dispersive spectroscopy confirmed favorable Ca/Si and Si/Al ratios that promote stability and strength.

The implications of this research are substantial for the energy and construction sectors. By reducing cement consumption and overall energy demand, this approach could lead to a 20%–25% potential energy saving during clinker production. “This study encourages the valorization of industrial by-products, reducing landfill waste and contributing to a circular economy,” Chouksey noted.

The findings suggest a promising path forward for sustainable construction. As the industry seeks to balance performance with environmental responsibility, the integration of lime sludge and metakaolin offers a viable solution. This research not only advances the field of sustainable materials but also underscores the importance of interdisciplinary collaboration in addressing global challenges.

As the construction industry continues to evolve, the adoption of such innovative materials could reshape the future of building practices, making them more sustainable and energy-efficient. The study’s success highlights the potential for industrial by-products to play a pivotal role in creating a greener, more resilient built environment.