In the quest for sustainable construction materials, researchers have uncovered a promising blend that could revolutionize the production of high-strength concrete. A recent study published in *Scientific Reports* (translated from Chinese as “Nature Communications”) explores the synergistic effects of rice husk ash (RHA) and extracted microsilica (EMS) as partial replacements for ordinary Portland cement (OPC). The findings, led by Muhammad Fahad Ullah from the Department of Disaster Mitigation for Structures at Tongji University’s College of Civil Engineering, offer a glimpse into a more eco-friendly future for the construction industry.

The study investigates the combined use of RHA and EMS, derived from agricultural waste and optimized extraction processes, respectively. By incorporating these materials into high-strength concrete (HSC), the research team observed significant improvements in mechanical strength and durability. “The strategic combination of EMS and RHA not only enhances the performance of concrete but also addresses the environmental concerns associated with traditional cement production,” Ullah explained.

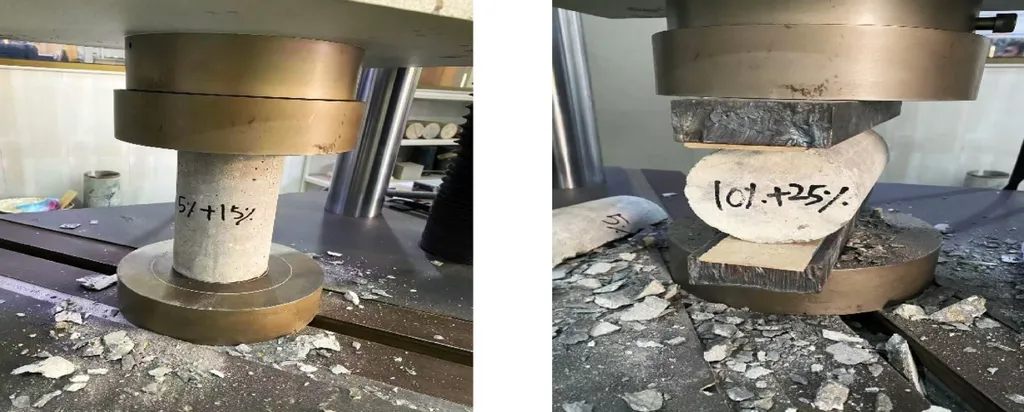

The researchers tested various mixes, with the most promising results coming from blends that replaced 20% and 35% of the cement with EMS and RHA. These mixes showed a notable increase in 28-day compressive strength, by 11.56% and 5.98%, respectively, compared to conventional concrete. Additionally, durability assessments revealed a significant reduction in water absorption and permeability, indicating a more robust and long-lasting material.

The study’s findings suggest that the optimized use of EMS and RHA can lead to the production of sustainable HSC with improved mechanical properties and durability. This advancement could have substantial commercial impacts, particularly in the energy sector, where the demand for durable and eco-friendly construction materials is growing. “The potential to reduce the environmental footprint of concrete production while maintaining high performance is a game-changer for the industry,” Ullah noted.

The research also highlights the importance of careful formulation, as mixes with higher replacement percentages showed inferior performance due to particle agglomeration and increased porosity. This nuanced understanding paves the way for further exploration and optimization of these materials in construction applications.

As the construction industry continues to seek sustainable alternatives, the findings from this study provide valuable insights into the potential of RHA and EMS blends. By leveraging agricultural waste and optimizing extraction processes, researchers are not only enhancing the performance of concrete but also contributing to global sustainability initiatives. This work underscores the importance of interdisciplinary collaboration in driving innovation and addressing the pressing challenges of our time.