In the quest for sustainable construction materials, a groundbreaking study led by Tan Hailong from the Longnan Highway Development Center of Gansu Province, China, has unveiled a promising approach to predicting the compressive strength of lightweight foamed concrete incorporating plastic waste. This research, published in the journal “Reviews on Advanced Materials Science” (translated from Chinese as “Advanced Materials Science Reviews”), could significantly impact the construction and energy sectors by optimizing mix designs and reducing experimental overhead.

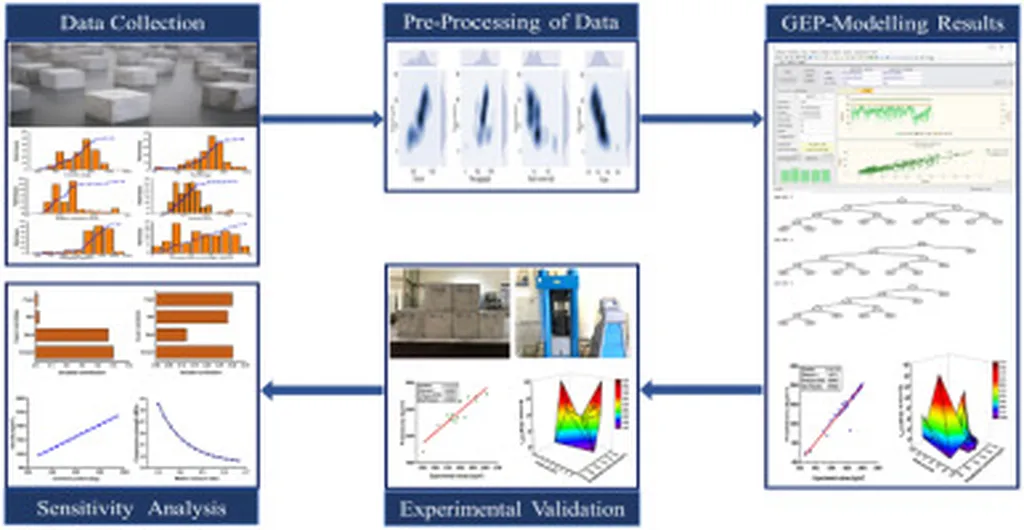

The study focuses on the predictive modeling of advanced concrete materials that use coated plastic waste as a sand replacement. By leveraging machine learning algorithms, the research team aimed to develop accurate, data-efficient models to forecast the compressive strength of foam concrete containing plastic waste. “Our goal was to reduce the need for extensive experimental trials and guide sustainable mix optimization,” explained Tan Hailong.

The research evaluated three predictive models: Random Forest (RF), Particle Swarm Optimization-Support Vector Regression (PSO-SVR), and a Genetic Algorithm Optimized Artificial Neural Network (GA-ANN). The models were assessed using R2 metrics, with RF scoring 0.9872 and 0.9005, and GA-ANN scoring 0.9979 and 0.8853 for the training and testing sets, respectively. These high R2 values indicate a strong predictive capability, suggesting that the models can reliably forecast the compressive strength of the material.

Sensitivity analyses were conducted to evaluate the impact of each input parameter on the compressive strength of the foam concrete. For the RF model, the highest Permutation Importance values were assigned to cement (0.39), foam (0.34), sand (0.17), water-to-cement ratio (0.11), and plastic waste (0.39). In the GA-ANN model, the greatest Permutation Importance Values were assigned to cement (0.41), sand (0.31), water-to-cement ratio (0.13), foam (0.11), and plastic waste (0.05). These findings highlight the critical role of cement and foam in determining the material’s strength.

The PSO-SVR model maintained a good balance with an AUC of 0.97 in training and 0.93 in testing. While its performance was average compared to the other models, it still demonstrated practicality in optimizing mix design and predicting performance metrics. The MAE value was approximately 1.5 in training and 2.8 in testing, whereas the RMSE value ranged from 4.5 to 5.0.

The implications of this research are far-reaching. By accurately predicting the compressive strength of foam concrete containing plastic waste, construction companies can reduce material costs and environmental impact. “This research opens up new possibilities for sustainable construction practices,” said Tan Hailong. “It allows us to make informed decisions about mix designs, ultimately leading to more efficient and eco-friendly construction processes.”

The energy sector could also benefit from these advancements. Lightweight foamed concrete is increasingly used in energy-efficient buildings, and the ability to optimize its mix design could enhance thermal insulation properties, reducing energy consumption. Additionally, the use of recycled plastic waste in construction materials aligns with global efforts to reduce plastic pollution and promote a circular economy.

As the construction industry continues to seek sustainable solutions, this research provides a robust framework for optimizing material performance. The integration of machine learning algorithms in predictive modeling offers a powerful tool for guiding future developments in the field. With further refinement and application, these models could revolutionize the way we approach sustainable construction, paving the way for a greener and more efficient future.