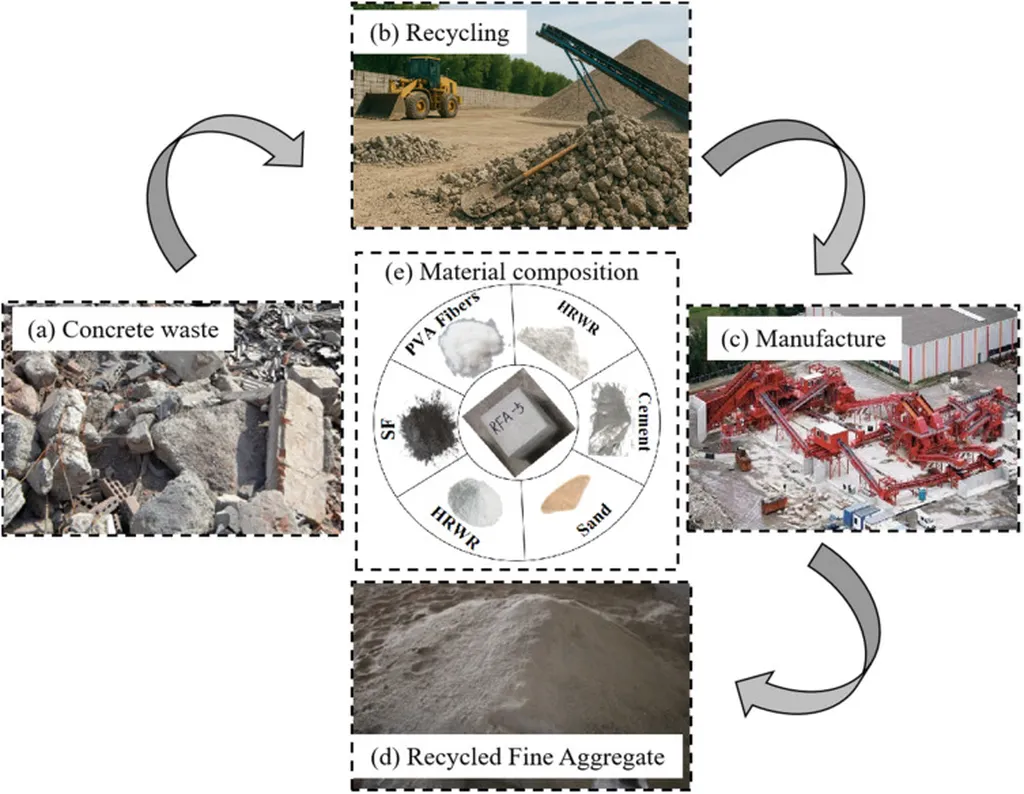

In a groundbreaking study published in the journal *Results in Engineering* (translated from Chinese as “Engineering Results”), researchers have explored the potential of incorporating construction waste into engineered cementitious composites (ECC), offering a promising avenue for sustainable construction practices and enhanced material performance under elevated temperatures. The study, led by Long Liu from the Henan Province Engineering Research Center of Material for Reinforcing Concrete Structure and Anyang Engineering Research Center of High Ductility Concrete Structure at Anyang Institute of Technology, along with the College of Safety Science and Engineering at Henan Polytechnic University, delves into the mechanical properties of ECC when partially replaced with micro-powder of construction waste (MPCW).

The research is particularly relevant to the energy sector, where the demand for durable, high-performance materials that can withstand extreme temperatures is paramount. By utilizing construction waste, the study not only addresses environmental concerns but also provides a cost-effective solution for enhancing material properties.

“Our findings indicate that while the incorporation of MPCW reduces the initial strength of ECC, the compressive strength loss remains within acceptable engineering design standards,” explained Long Liu. “This means that we can effectively use construction waste in ECC without compromising structural integrity, which is a significant step towards sustainable construction practices.”

The study investigated the mechanical behavior of ECC with MPCW substitution within a temperature range of 20 °C to 600 °C. The results showed that as the temperature rises, the compressive, tensile, and flexural tensile strengths of MPCW-ECC, along with their corresponding strains, initially increase and then decrease. Notably, when the temperature exceeds 300 °C, the failure mode becomes more brittle, and above 400 °C, the compressive strength drops to less than 75% of the control group.

“Understanding the behavior of these materials at high temperatures is crucial for their application in energy-intensive environments,” said Long Liu. “Our research provides a scientific basis for the elevated-temperature safety evaluation of MPCW-ECC, which can guide future developments in the field.”

The study also employed X-ray diffraction (XRD) and scanning electron microscopy (SEM) to analyze the crystal phase transformations and microstructural evolution of the materials. The findings revealed that the crystal phase transformations of ECC and MPCW-ECC matrices at different temperatures were highly consistent with macroscopic performance trends. Additionally, a regression model established for MPCW-ECC mechanical properties showed high predictive accuracy, with R² values of 0.911, 0.880, and 0.865 for compressive, tensile, and flexural tensile strengths, respectively.

This research not only highlights the potential of construction waste in enhancing the mechanical properties of ECC but also offers valuable insights into the sustainable utilization of waste materials in the construction industry. As the energy sector continues to demand high-performance materials that can withstand extreme conditions, the findings from this study could pave the way for innovative and eco-friendly construction practices.

“By integrating construction waste into ECC, we are not only reducing environmental impact but also developing materials that meet the stringent requirements of the energy sector,” concluded Long Liu. “This research opens up new possibilities for sustainable construction and material science, offering a blueprint for future developments in the field.”