In a significant stride towards sustainable construction materials, researchers have developed a novel bio-derived composite using date palm trunk fibers and okra, offering a promising alternative to traditional insulation materials. This innovative approach not only addresses the pressing issue of deforestation but also provides a viable solution for utilizing agro-industrial by-products.

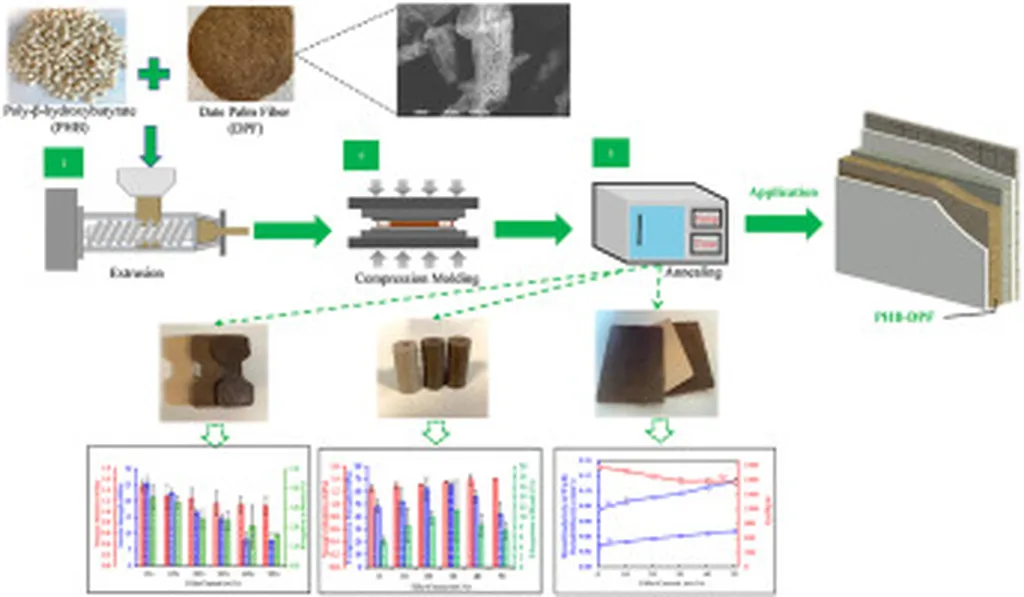

The study, led by Amged ElHassan from the Department of Mechanical Engineering at the United Arab Emirates University, fabricated composites with varying okra content (0–50 wt. percentage) using a simple compression molding technique. The results, published in the ‘International Journal of Thermofluids’ (translated as ‘International Journal of Heat and Fluid Flow’), reveal that increasing the okra proportion enhances interfacial bonding and minimizes porosity, leading to improved mechanical strength and thermal insulation properties.

“Our findings demonstrate that the compressive strength of the composites can reach up to 28 MPa, and the elastic modulus can go up to 0.49 GPa,” ElHassan explained. “This makes them suitable for various construction applications, particularly in arid climates where thermal insulation is crucial.”

The composites exhibited thermal conductivity values ranging from 0.051 to 0.067 W/m.K at room temperature, confirming their suitability for insulation applications. Additionally, the materials showed high thermal stability with only an 11% mass loss at 270 °C and achieved a maximum acoustic absorption coefficient of 0.9, indicating excellent sound absorption properties.

The specific heat capacity values of the composites were found to be between 1.35 × 10³ and 2.38 × 10³ J/kg·K, with corresponding thermal diffusivity values between 0.0307 and 0.0651 mm²/s. These properties reflect effective heat storage, making the composites highly efficient for thermal management in buildings.

The research highlights the potential of valorizing date palm trunk fibers and okra residues into bio-based composites without the need for toxic ingredients, pretreatment, or sophisticated processing. This innovative approach not only reduces environmental impact but also offers a cost-effective solution for the construction industry.

The implications of this research are far-reaching, particularly for the energy sector. As the world increasingly focuses on sustainability and reducing carbon footprints, the development of green thermal insulation materials becomes paramount. The use of agro-industrial by-products in constructing bio-based composites presents a viable alternative to traditional materials, offering both environmental and economic benefits.

“This study opens up new avenues for the utilization of agricultural waste in the construction industry,” ElHassan noted. “It paves the way for more sustainable and eco-friendly building materials that can contribute to reducing deforestation and promoting a circular economy.”

As the construction industry continues to evolve, the adoption of such innovative materials can significantly impact energy efficiency and environmental sustainability. The research conducted by ElHassan and his team represents a significant step forward in this direction, offering a glimpse into the future of sustainable construction materials.