In the quest to reduce the construction industry’s significant carbon footprint, researchers are turning to an unconventional yet promising material: biochar. A recent study published in the *e-Journal of Nondestructive Testing* (translated from German as *e-Journal of Non-Destructive Testing*) explores how the pore structure of biochar influences its performance as a concrete admixture, offering insights that could reshape sustainable construction practices.

Biochar, a byproduct of pyrolysis—a process that converts agricultural and forestry waste into a carbon-rich substance—has garnered attention for its potential to enhance concrete properties while acting as a carbon sink. However, its incorporation into concrete has posed challenges, particularly in maintaining compressive strength. Lead author Hatice Kilci and her team set out to understand how biochar’s microstructure affects its load-bearing and filtering capabilities in cementitious systems.

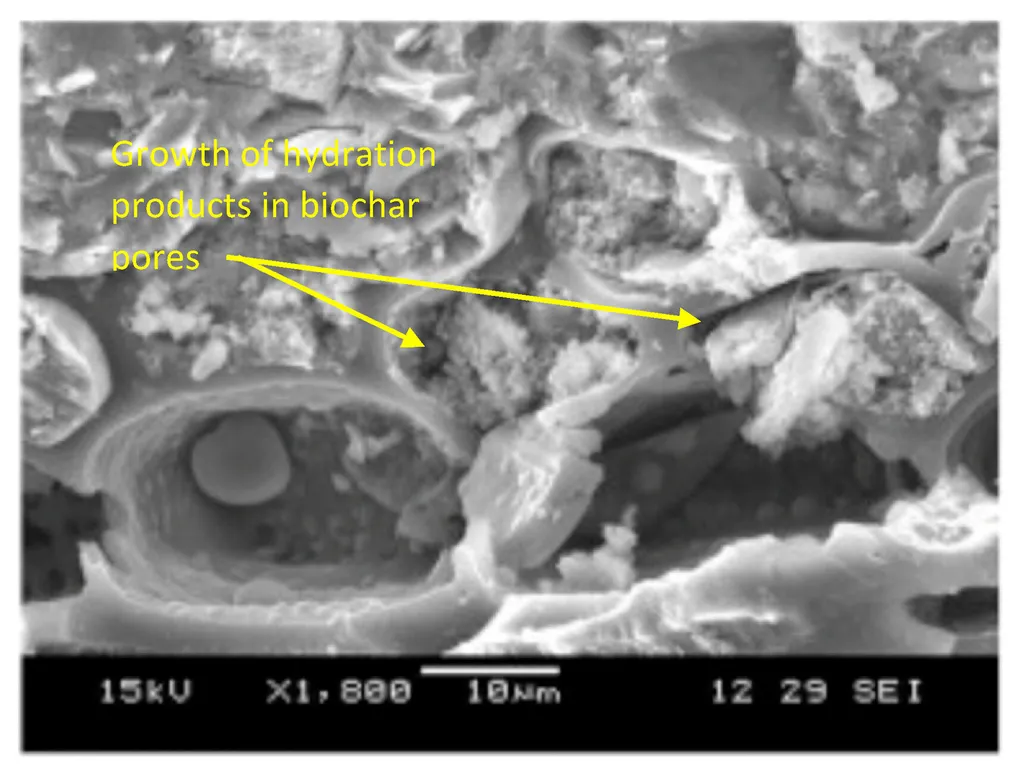

The study began by characterizing the biochar microstructure using synchrotron-based computed tomography (SXCT), which quantified pore size, wall thickness, and porosity. “We found significant variations in pore sizes among different biochars, but the wall thicknesses remained relatively consistent,” Kilci noted. This variability in pore structure plays a crucial role in how biochar interacts with cement paste, influencing both mechanical strength and moisture absorption.

One of the most compelling findings was biochar’s enhanced moisture absorption. Using ¹H-NMR (proton nuclear magnetic resonance) tests, the researchers observed that biochar-containing mortar absorbed significantly more moisture than control samples. This property could be particularly beneficial for filter applications, where moisture retention is essential. “The spatial moisture distribution measured by XCT and the moisture profiles determined by ¹H-NMR provided clear evidence of biochar’s superior moisture absorption capabilities,” Kilci explained.

The study also investigated biochar’s ability to absorb chloride ions, a critical factor in concrete durability. Using ICP-OES (inductively coupled plasma optical emission spectrometry), the team confirmed that biochar effectively absorbs chloride ions, with absorption increasing over time. This finding underscores biochar’s potential as a protective additive in concrete, enhancing its resistance to corrosion and degradation.

However, the research also highlighted a significant challenge: the reduction in mechanical strength when biochar is incorporated into concrete. Despite this drawback, the study suggests that the benefits of biochar—such as improved moisture retention and filtration properties—could outweigh the negatives, particularly in applications where sustainability is a priority.

The commercial implications of this research are substantial. As the energy sector increasingly focuses on reducing carbon emissions, the construction industry is under pressure to adopt more sustainable practices. Biochar offers a promising avenue for achieving this goal, providing a multifunctional additive that can enhance concrete performance while reducing environmental impact.

Kilci’s research provides valuable insights into the complex relationships between biochar microstructure, mechanical performance, and filter capabilities. While further studies are needed to fully understand these dynamics, the findings offer a compelling case for biochar as a key player in the future of sustainable construction.

As the construction industry continues to evolve, the integration of biochar into concrete mixtures could become a standard practice, driven by the need for greener building materials. This research not only advances our understanding of biochar’s potential but also paves the way for innovative solutions that could significantly reduce CO₂ emissions in the construction sector.