In the quest for sustainable construction materials, researchers have made significant strides in developing geopolymer concrete (GPC) that not only reduces carbon emissions but also incorporates recycled materials. A recent study led by Suhad Al-Saedi from the Civil Engineering College at the University of Technology in Baghdad, Iraq, published in the Engineering and Technology Journal (Mujala’at Al-Hindasa Wal-Teqniya), explores the properties of modified metakaolin-based GPC with two types of waste aggregate. This research could have profound implications for the energy sector, particularly in reducing the carbon footprint of construction projects.

The study focuses on enhancing the binder by replacing 5% of metakaolin with calcium oxide and silica fume by weight. Additionally, to reduce environmental impact, 10% of the natural coarse aggregate volume was substituted with crumb rubber and shredded plastic waste. “The incorporation of recycled materials is a crucial step towards achieving sustainable construction practices,” Al-Saedi explains. “Our goal was to assess how these modifications affect the mechanical and durability properties of geopolymer concrete.”

The research involved a detailed mix design using specific proportions of materials, including metakaolin, coarse aggregates, fine aggregate, sodium hydroxide, sodium silicate, water, and superplasticizer. The study evaluated mechanical properties such as compressive strength, splitting tensile strength, and modulus of elasticity, alongside durability metrics like water absorption, permeability, abrasion resistance, and shrinkage.

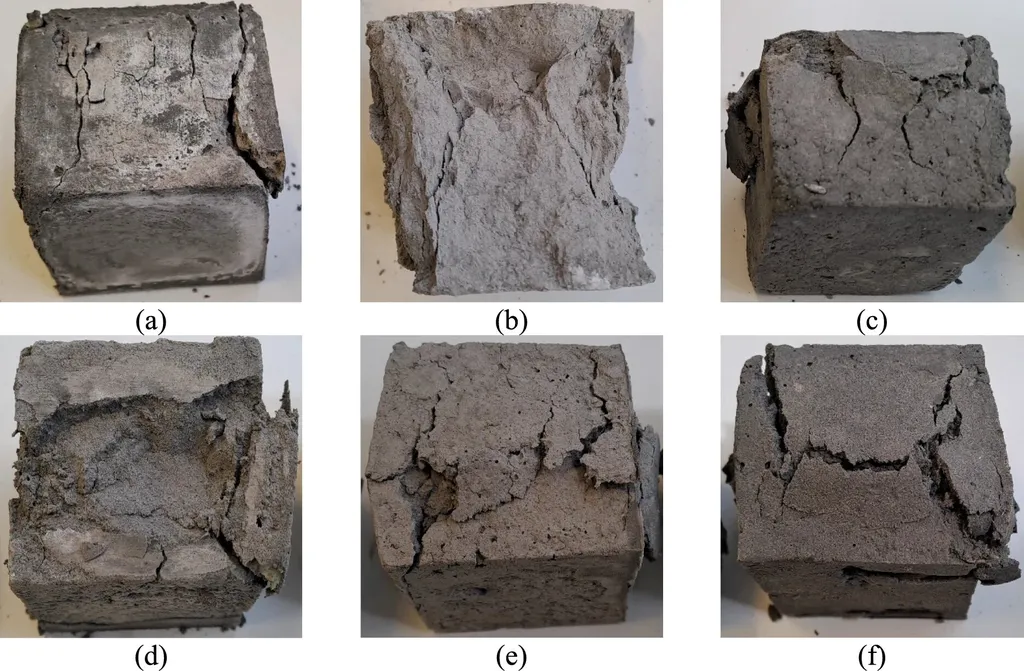

The findings revealed that the incorporation of recycled materials resulted in some performance reductions. Compressive strength decreased by 25% with crumb rubber and 34% with shredded plastic waste. Tensile strength saw reductions of 17% and 41%, respectively, while the modulus of elasticity decreased by 10% and 33%. Despite these declines, the modified geopolymer concrete demonstrated improved permeability, abrasion resistance, and shrinkage, remaining within acceptable limits.

Microstructural analyses confirmed the beneficial effects of recycled materials on matrix integrity. “The use of geopolymer concrete as a sustainable, low-carbon construction material is not only feasible but also beneficial in the long run,” Al-Saedi notes. “The improvements in durability metrics are particularly encouraging for the energy sector, where long-term performance is crucial.”

This research could shape future developments in the field by promoting the use of recycled materials in construction. The energy sector, in particular, stands to benefit from the reduced carbon footprint and improved durability of geopolymer concrete. As the demand for sustainable construction materials continues to grow, the findings of this study provide a promising avenue for innovation and development.

The study, published in the Engineering and Technology Journal, offers a comprehensive analysis of the properties of modified metakaolin-based geopolymer concrete with recycled aggregates. The research not only highlights the potential of geopolymer concrete as a sustainable alternative to traditional cement-based materials but also underscores the importance of incorporating recycled materials in construction. As the world moves towards a more sustainable future, the insights from this study could pave the way for groundbreaking advancements in the field of construction materials.