In a groundbreaking development poised to revolutionize sustainable construction practices, researchers have harnessed the power of machine learning to predict the compressive strength of self-compacting concrete (SCC) incorporating recycled materials. This innovative approach not only promotes environmental sustainability but also offers significant commercial benefits, particularly for the energy sector.

At the helm of this research is Kavendra Pulkit, a distinguished scientist from the National Institute of Technology Kurukshetra. Pulkit and his team have developed a robust machine learning framework that can accurately predict the compressive strength of SCC mixes using recycled coarse aggregate (RCA) and supplementary cementitious materials (SCMs). “This study demonstrates the potential of machine learning models to replace time-consuming laboratory tests, providing a data-driven framework for optimizing concrete mix design,” Pulkit explained.

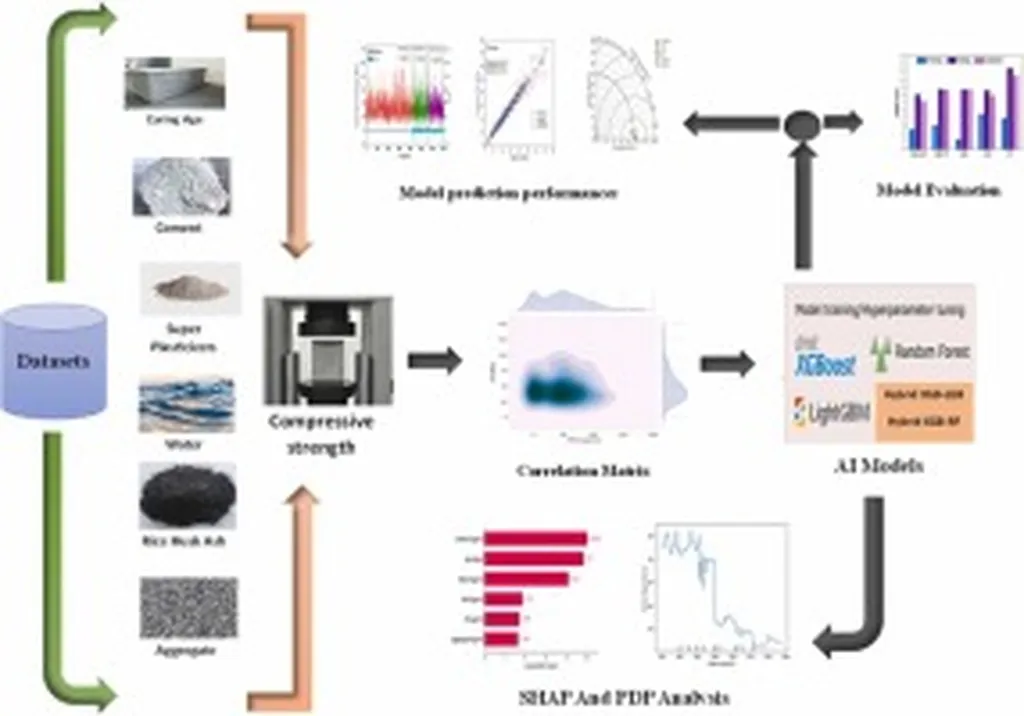

The research, published in the Journal of Materials and Engineering Structures (Revue des Matériaux et des Structures), utilized a comprehensive dataset comprising 337 SCC mixes. The dataset included varying input parameters such as cement content, SCMs, water to binder ratio, and curing age. Five regression models were evaluated, with Gradient Boosting emerging as the most accurate, achieving an impressive R² value of 0.8876.

The implications of this research are far-reaching, particularly for the energy sector. The ability to predict the compressive strength of SCC with high accuracy using recycled materials can significantly reduce the environmental footprint of construction projects. This is particularly relevant for energy infrastructure, where large-scale construction often requires substantial amounts of concrete.

Moreover, the use of machine learning models can streamline the design process, reducing the time and cost associated with traditional laboratory testing. “This technology can accelerate the adoption of sustainable construction practices, making it easier for companies to meet environmental regulations and achieve their sustainability goals,” Pulkit added.

The study also highlights the importance of interpretability in machine learning models. SHAP (SHapley Additive exPlanations) analysis revealed that cement content and curing age were the most influential parameters in predicting compressive strength. This insight can guide engineers and researchers in optimizing concrete mix designs for specific applications.

As the construction industry continues to evolve, the integration of machine learning and sustainable materials is expected to play a pivotal role. This research not only sets a precedent for future developments but also underscores the importance of interdisciplinary collaboration in driving innovation.

In the words of Kavendra Pulkit, “The future of construction lies in the intersection of technology and sustainability. By leveraging machine learning and recycled materials, we can build a more resilient and environmentally friendly infrastructure.”