In a groundbreaking study published in the *Journal of Materials and Engineering Structures* (translated from French as *Journal of Materials and Structures Engineering*), researchers have uncovered a promising solution to two pressing environmental challenges: the disposal of waste bottle glass and the over-extraction of natural sand. The research, led by Ahmed Hatif Obaid from the University of Misan, explores the feasibility of using crushed waste bottle glass as a sustainable alternative to sand in cement mortar.

The construction industry has long relied on natural sand as a key component in cement mortar, but its extraction has led to environmental degradation and habitat destruction. Meanwhile, the world grapples with a growing waste glass problem, with millions of tons ending up in landfills each year. Obaid’s research offers a dual solution to these issues by demonstrating that waste bottle glass can effectively replace sand in cement mortar, promoting a circular economy and reducing the industry’s environmental footprint.

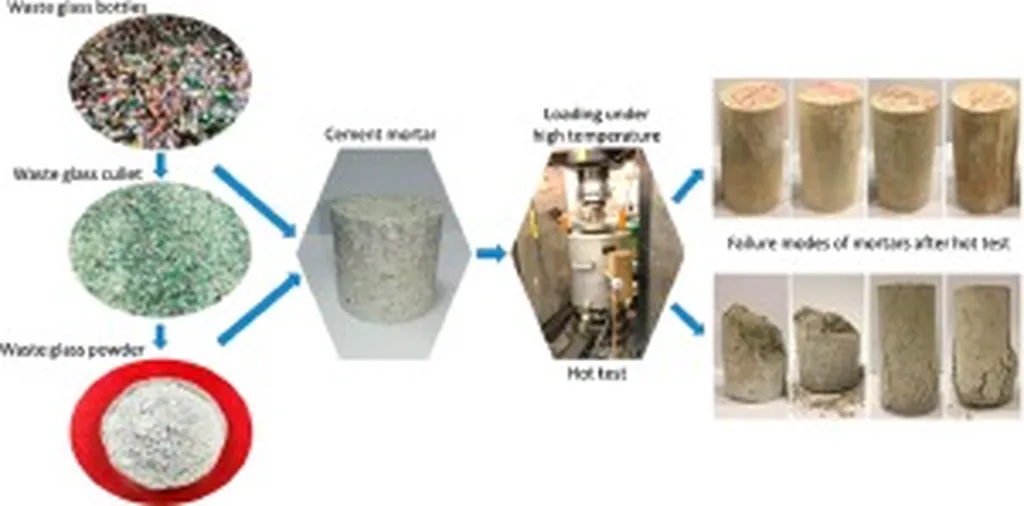

The study involved casting several cement mortar mixes with varying ratios of sand to cement (1:2 and 1:3) and replacing sand with crushed waste bottle glass at replacement ratios ranging from 5% to 100%. The researchers evaluated the mixes for workability, compressive strength, tensile strength, flexural strength, and flexural modulus.

The findings revealed that incorporating 10–15% glass into 1:2 mixtures significantly enhanced their ductility and mechanical strength. Moreover, under optimal conditions, complete replacement (100%) proved to be structurally viable. “The results were quite remarkable,” Obaid stated. “We found that not only can waste glass be used to replace sand, but it can also improve the performance of the mortar in certain cases.”

However, the study also highlighted some challenges. For instance, workability decreased in 1:3 mixes due to excessive fines and inadequate cohesion, while it improved significantly in low-glass 1:2 mixes. “This indicates that the optimal use of waste glass may depend on the specific mix design and its intended application,” Obaid explained.

The implications of this research for the construction industry are substantial. By adopting these eco-friendly mix designs, builders can reduce their reliance on natural sand, mitigate environmental damage, and contribute to waste reduction. “This is a win-win situation,” Obaid remarked. “We can build more sustainably while also addressing a significant waste problem.”

The study’s findings pave the way for future developments in sustainable construction materials. As the industry continues to seek innovative solutions to environmental challenges, the use of waste bottle glass in cement mortar could become a standard practice, shaping the future of green building.

In the broader context, this research aligns with global efforts to promote the circular economy, where waste materials are repurposed and reused, minimizing the need for virgin resources. As the world grapples with the impacts of climate change and resource depletion, such innovations are crucial for building a more sustainable future.

The study, titled “Producing Sustainable Cement Mortar by Replacing Sand with Waste Bottle Glass,” was published in the *Journal of Materials and Engineering Structures*, a renowned publication in the field of materials science and engineering. The research not only advances scientific knowledge but also offers practical solutions for the construction industry, highlighting the potential of waste materials in creating sustainable and high-performance building materials.