In a world increasingly focused on sustainability, researchers are turning to unconventional materials to create high-performance composites. A recent study published in the journal *Materials Research Express* explores the potential of banana fibres, often considered agricultural waste, to enhance the mechanical properties of hybrid composites. The research, led by Kanchan B M from the Department of Aeronautical and Automobile Engineering at Manipal Institute of Technology, Manipal Academy of Higher Education (MAHE), India, could have significant implications for industries seeking lightweight, impact-resistant materials.

The study focuses on the integration of natural banana fibres with synthetic carbon-Kevlar intraply fibres in a sandwich configuration. This hybrid design aims to leverage the sustainability, low density, and biodegradability of banana fibres alongside the high strength and impact resistance of carbon and Kevlar. “The idea was to create a material that not only performs well mechanically but also aligns with sustainable practices,” explains Kanchan B M.

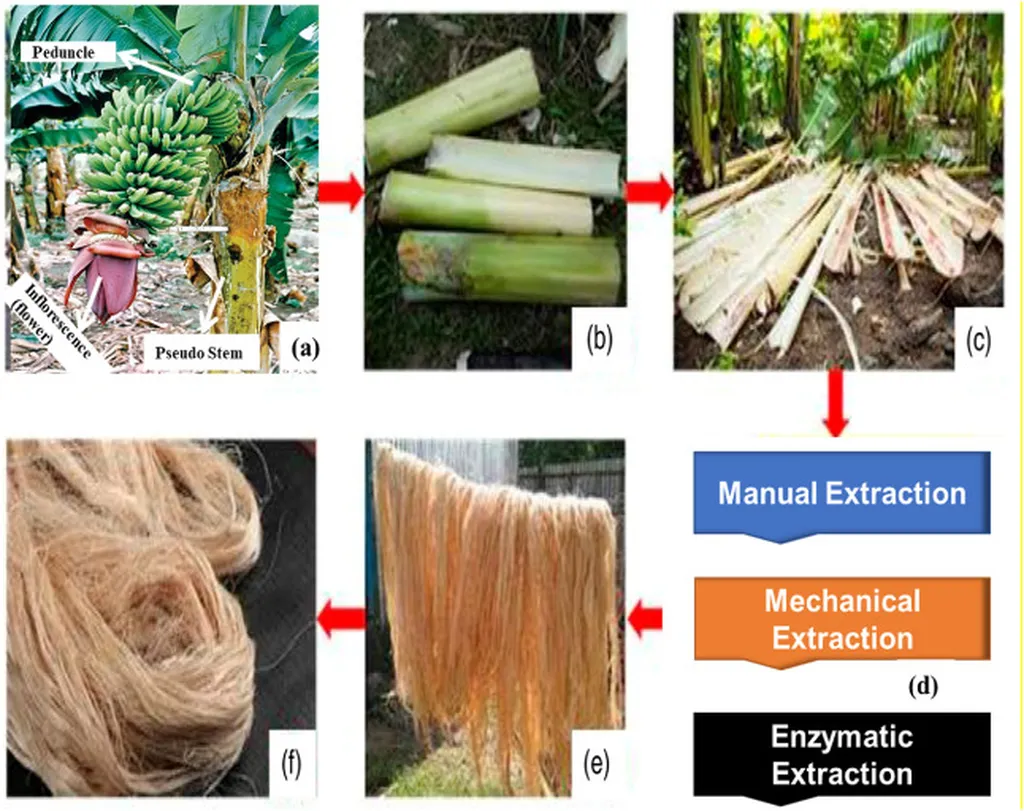

To enhance the fibre-matrix bonding, the banana fibres were subjected to chemical treatments using 5% NaOH and 0.5% KMnO4. These treatments aimed to improve the fibre surface characteristics and interfacial bonding. The laminates were then fabricated by sandwiching the treated banana fibre layers between carbon-Kevlar intraply layers using hand lay-up and compression molding.

The mechanical performance of these composites was evaluated through tensile, flexural, and Charpy impact tests. The results were promising, with both chemical treatments improving the mechanical properties compared to untreated composites. Notably, the KMnO4 treatment yielded the highest tensile strength (87.98 MPa), flexural strength (104.12 MPa), and impact strength (34.19 kJ m−2).

Scanning Electron Microscopy (SEM) revealed improved fibre-matrix adhesion and altered fracture morphologies corresponding to the different treatment types. These findings suggest that the hybrid composites have significant potential for sustainable high-performance applications in aerospace, automotive, and structural industries, where lightweight and impact-resistant materials are essential.

The research contributes to several Sustainable Development Goals (SDGs), including SDG 9 (Industry, Innovation, Infrastructure), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action). By advancing sustainable materials from agricultural waste, this study opens new avenues for innovation in the energy sector and beyond.

As industries continue to seek materials that balance performance and sustainability, the findings from this study could shape future developments in composite materials. The integration of natural fibres like banana with high-performance synthetic fibres offers a promising path forward, one that aligns with both technological advancements and environmental responsibility.

For professionals in the energy sector, this research highlights the potential of sustainable materials to meet the demands of high-performance applications. As Kanchan B M notes, “The future of materials lies in our ability to innovate while respecting the environment. This study is a step in that direction.”