In the quest for sustainable construction materials, researchers have turned to industrial by-products, finding promising results that could reshape the energy and construction sectors. A recent study published in the Ain Shams Engineering Journal, translated as the Journal of Ain Shams University for Engineering Sciences, explores the potential of ground granulated blast furnace slag (GGBS) and ladle furnace slag (LFS) as valuable resources in cement-based materials, offering a greener alternative to traditional cement production.

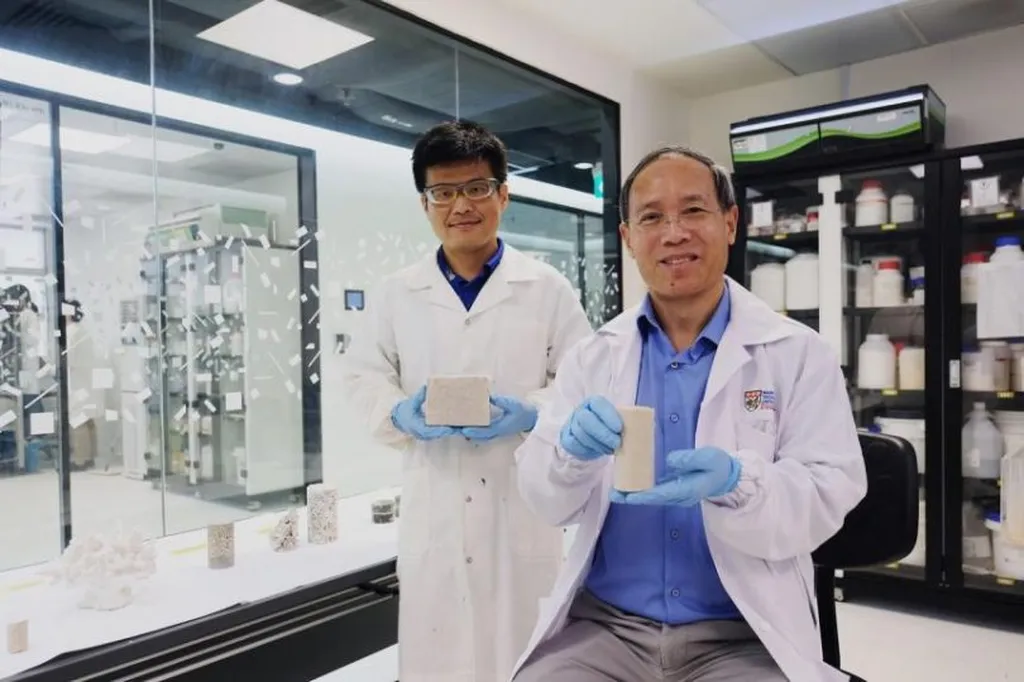

The research, led by Chee Lok Yong from the Department of Civil Engineering at Universiti Malaya in Kuala Lumpur, Malaysia, investigates the early-age mechanical properties and carbonation behavior of blended cement mortars incorporating GGBS and LFS. The study subjects these materials to accelerated CO2 curing (ACC), a process that could significantly reduce the carbon footprint of construction materials.

“Our findings indicate that GGBS can replace cement up to 50% while maintaining early strength through the formation of C-S-H, a key compound in cement hydration,” Yong explains. This is a significant discovery, as it demonstrates the potential for substantial reductions in cement usage, a major source of carbon emissions in the construction industry.

In contrast, the study found that LFS is effective only up to 10% replacement, as excess amounts lead to weaker C-A-H formation. However, the research also reveals that under ACC, GGBS-blended cement undergoes greater carbonation, effectively sequestering CO2 and turning it into a valuable resource. “This highlights the importance of tailoring ACC parameters to slag composition,” Yong notes, emphasizing the need for customized approaches to maximize performance.

The implications for the energy and construction sectors are substantial. By incorporating industrial by-products like GGBS into cement-based materials, the construction industry can significantly reduce its carbon emissions. Moreover, the use of ACC can transform these materials into CO2-reactive resources, further enhancing their sustainability.

“This research demonstrates the potential of ACC to improve performance in GGBS-based green cement,” Yong concludes. “However, its benefit in LFS systems is limited by its inherent mineralogical stability. Tailoring ACC parameters to slag composition is crucial for maximizing performance and supporting the transition toward more sustainable and low-carbon construction technologies.”

As the world grapples with the challenges of climate change, innovative research like this offers a glimmer of hope. By turning industrial by-products into valuable resources and developing processes that sequester CO2, the construction industry can play a pivotal role in the global effort to reduce carbon emissions. The study’s findings could shape future developments in the field, paving the way for a more sustainable and low-carbon future.