In the heart of Europe’s push towards a greener, more efficient transportation network, a humble yet innovative construction technique is gaining traction, promising to revolutionize railway maintenance and durability. As the continent races to meet the ambitious emission reduction targets set by the 2050 European Green Deal, researchers like Aldo La Placa from the University of Parma are exploring ways to enhance the railway infrastructure, particularly the ballasted track design.

La Placa, a leading expert in transportation science and technology, has been investigating the use of asphalt sub-ballast, a technique derived from road construction, which has been quietly transforming high-speed (HS) and high-capacity (HC) rail lines since the 1970s. His recent study, published in the International Journal of Transportation Science and Technology (translated as the International Journal of Transportation Science and Technology), offers a critical review of this technology, highlighting its technical characteristics and long-term performances.

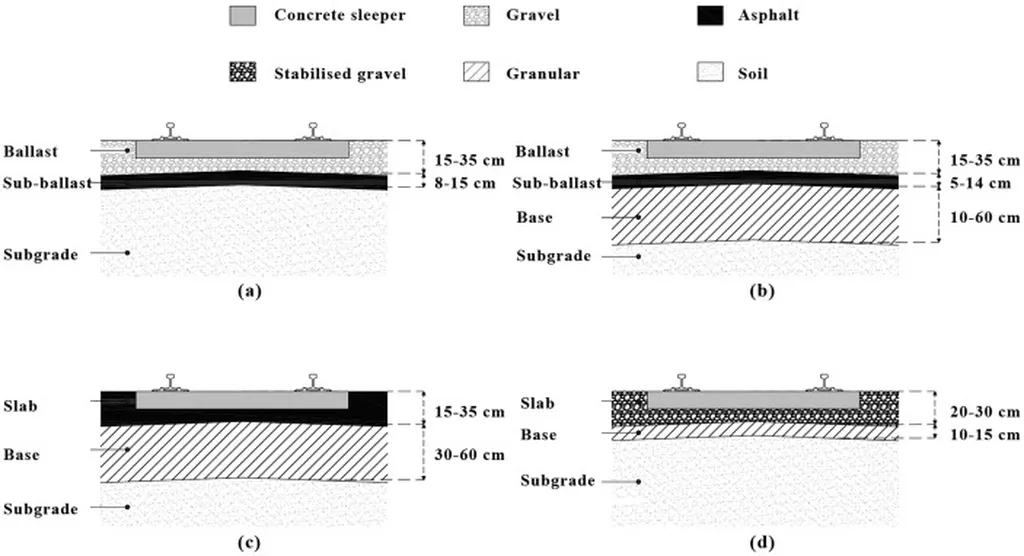

The asphalt sub-ballast, also known as asphalt underlayment (AUL), is a layer of bituminous material placed between the ballast and the subgrade. It serves as a protective barrier, improving the track’s stability and load distribution, enhancing water drainage, and reducing fatigue-induced phenomena. “The enhanced properties of asphalt sub-ballast lead to lower maintenance costs and operations, particularly those related to ballast tamping, as well as to an extended service life of the whole infrastructure,” La Placa explains.

The commercial impacts of this research are significant, especially for the energy sector. As Europe’s railway network expands and upgrades to meet the growing demand for sustainable transport, the need for durable, low-maintenance infrastructure becomes paramount. The use of asphalt sub-ballast can help reduce the lifecycle costs of railway lines, making them a more attractive option for both public and private investors.

Moreover, the study highlights the potential of asphalt sub-ballast to contribute to the circular economy. By reusing or recycling wastes and by-products in these mixes, the cost-benefit ratio is amplified, and their sustainability is improved. This aspect is particularly relevant in the current context of resource scarcity and climate change, where the efficient use of materials and energy is crucial.

The research conducted by La Placa and his team is not just about improving the performance of railway lines. It’s about shaping the future of transportation, making it more sustainable, efficient, and resilient. As the European railway network continues to grow and evolve, the role of innovative construction techniques like asphalt sub-ballast will become increasingly important.

In the words of La Placa, “The use of asphalt sub-ballast is a proven technology that can significantly enhance the durability and functionality of the railway infrastructure. Its potential to reduce maintenance costs and extend the service life of railway lines makes it a valuable tool in the pursuit of a greener, more efficient transportation network.”

As we look to the future, it’s clear that the humble asphalt sub-ballast has a vital role to play in the evolution of Europe’s railway network. Its ability to improve track stability, reduce maintenance costs, and contribute to the circular economy makes it a key player in the quest for sustainable, efficient, and resilient transportation. And with researchers like Aldo La Placa at the helm, the future of railway infrastructure looks brighter than ever.