In the quest for sustainable construction materials, researchers have turned to an unlikely duo: palm kernel shells and laterite. A recent study published in the journal *Sustainable Structures* (which translates to *Durable Structures* in English) explores the potential of these materials as eco-friendly alternatives to traditional concrete aggregates. The research, led by Mark Omeiza Onipe of the Department of Building at Delta State University of Science and Technology in Nigeria, could reshape the construction industry’s approach to sustainability and durability.

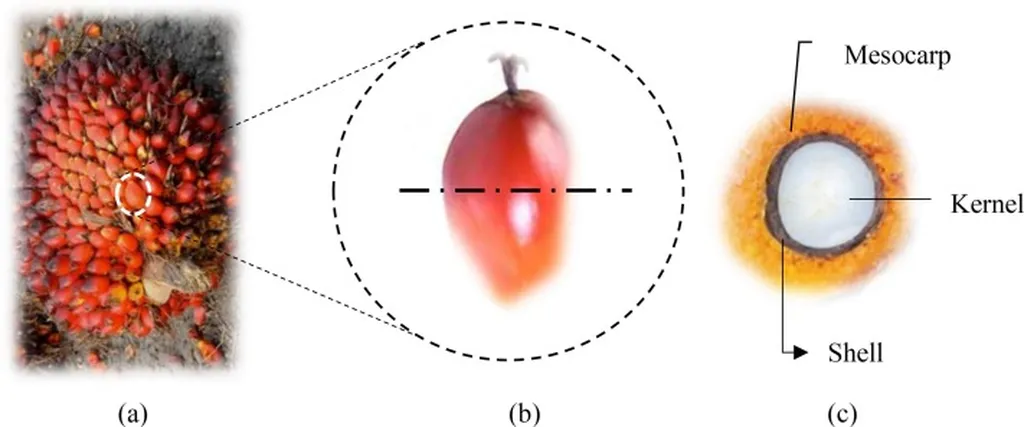

Concrete is a cornerstone of modern construction, but its production comes at a significant environmental cost. Traditional aggregates like granite and sand are finite resources, and their extraction often leads to habitat destruction and soil erosion. Enter palm kernel shells (PKS) and laterite, abundant byproducts of the palm oil industry and naturally occurring soil, respectively. “We saw an opportunity to repurpose these materials, reducing waste and conserving natural resources,” Onipe explains.

The study focused on void content and initial surface absorption, critical factors in determining concrete’s durability and resistance to environmental stressors. By varying the water-cement ratio and the proportion of PKS and laterite, the researchers evaluated how these materials perform under different conditions. The findings were promising: a mix containing 10% PKS and 10% laterite demonstrated durability metrics comparable to traditional concrete, even in severe coastal environments.

“This is a game-changer for the construction industry,” Onipe says. “We can now consider PKS-laterized concrete for a wide range of applications, from urban buildings to coastal infrastructure, without compromising on performance.”

The implications for the energy sector are particularly noteworthy. Coastal and offshore energy installations, such as wind farms and oil rigs, require materials that can withstand harsh environmental conditions. PKS-laterized concrete could provide a sustainable solution, reducing the environmental footprint of these projects while ensuring long-term durability.

Moreover, the use of PKS and laterite aligns with global sustainability goals, promoting resource conservation and waste reduction. As the world grapples with climate change and resource depletion, innovative solutions like PKS-laterized concrete offer a beacon of hope. “This research is just the beginning,” Onipe notes. “We need to continue exploring and refining these mixes to optimize their performance and applicability.”

The study published in *Sustainable Structures* opens new avenues for eco-friendly construction materials, paving the way for a more sustainable future. As the construction industry embraces these innovations, the energy sector stands to benefit from enhanced durability and reduced environmental impact. The journey towards sustainable construction is underway, and PKS-laterized concrete is leading the charge.