In the quest for sustainable construction materials, researchers have been exploring geopolymers as a promising alternative to traditional cement. Now, a study published in the *Journal of Sustainable Construction Materials and Technologies* (translated from Turkish as *Journal of Sustainable Construction Materials and Technologies*) sheds new light on how microwave curing can significantly enhance the performance of slag-based geopolymer mortars. The research, led by Abdulkadir Çevik from the Department of Civil Engineering at Gaziantep University in Turkey, offers intriguing insights that could reshape the construction industry’s approach to material curing and strength development.

Geopolymers, known for their eco-friendly properties, have long been touted as a potential replacement for cement. However, their widespread adoption has been hindered by challenges related to strength development and curing times. Çevik’s study addresses these issues head-on by investigating the effects of microwave curing on the compressive strength of slag-based geopolymers.

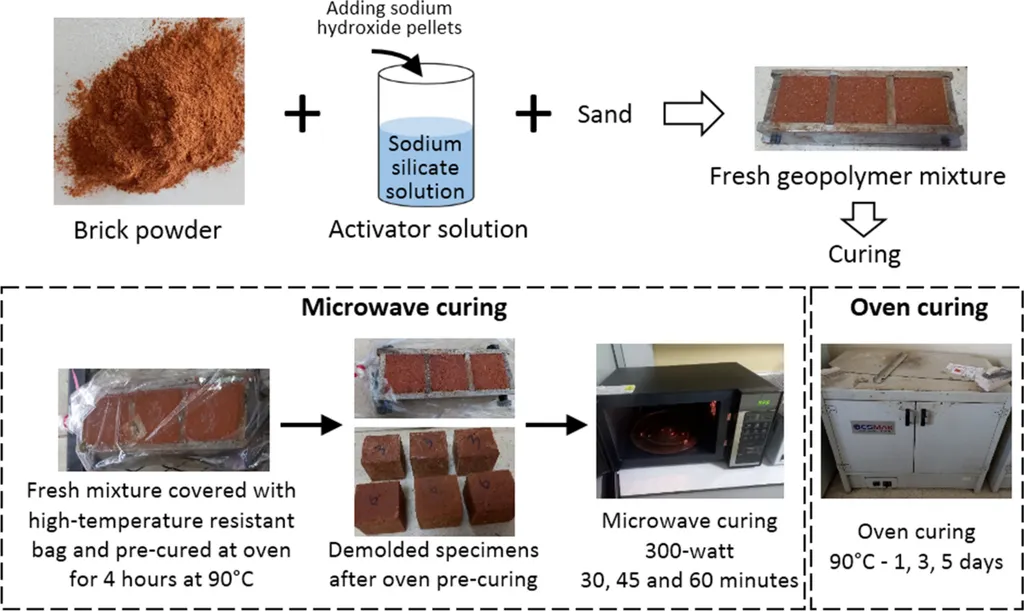

The research involved subjecting demolded mortar specimens to different microwave curing energies (ranging from 300 to 800 Watts) for varying durations (10 to 60 minutes) after one day of initial curing. Compressive strength tests were then conducted on both cured and uncured specimens at 1, 7, and 28 days. The results were striking. “Microwave curing could increase the strength about 10 times in just one day, reaching a compressive strength of 36.47 MPa, which is almost equal to the 28-day strength of uncured specimens,” Çevik explained. This dramatic improvement in early strength development opens up new possibilities for accelerating construction processes and reducing project timelines.

The study also delved into the underlying mechanisms behind these strength improvements. Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray (EDX) analyses revealed correlations among EDX results, color changes, and compressive strength values. “There may be a significant relationship between the chemical composition, visual changes, and the mechanical properties of the geopolymers,” Çevik noted. However, the research also cautioned against the use of excessively high microwave energies. Specimens subjected to 800-Watt curing showed signs of decay and durability problems, with decreased strength at later ages. “It is recommended to avoid applying such high energies to slag-based geopolymers,” Çevik advised.

The implications of this research are far-reaching for the construction industry, particularly in the context of sustainable and energy-efficient practices. By optimizing microwave curing techniques, construction professionals can potentially achieve faster strength development in geopolymer materials, leading to reduced construction times and improved project efficiency. This could be particularly beneficial for large-scale infrastructure projects, where time and cost savings are critical.

Moreover, the study highlights the importance of understanding the intricate relationships between curing conditions, material properties, and long-term performance. As the construction industry continues to seek innovative solutions for sustainable development, geopolymers and advanced curing techniques like microwave curing are likely to play a pivotal role. “This research provides a foundation for further exploration into the optimization of geopolymer curing processes,” Çevik concluded. “It offers a glimpse into the potential of microwave curing to revolutionize the way we approach material strength development in construction.”

As the industry moves towards more sustainable and efficient practices, the findings from this study could pave the way for new advancements in construction materials and techniques. By harnessing the power of microwave curing, construction professionals can unlock the full potential of geopolymers, contributing to a more sustainable and resilient built environment.