In the quest for sustainable construction materials, a team of researchers led by Ahmed AL-Mowafy from the Structural Engineering Department at Mansoura University has made a significant breakthrough. Their work, recently published in the journal “Scientific Reports” (translated to English as “Scientific Reports”), introduces a novel type of hybrid geopolymer concrete (HGC) that could revolutionize the construction industry and offer substantial benefits to the energy sector.

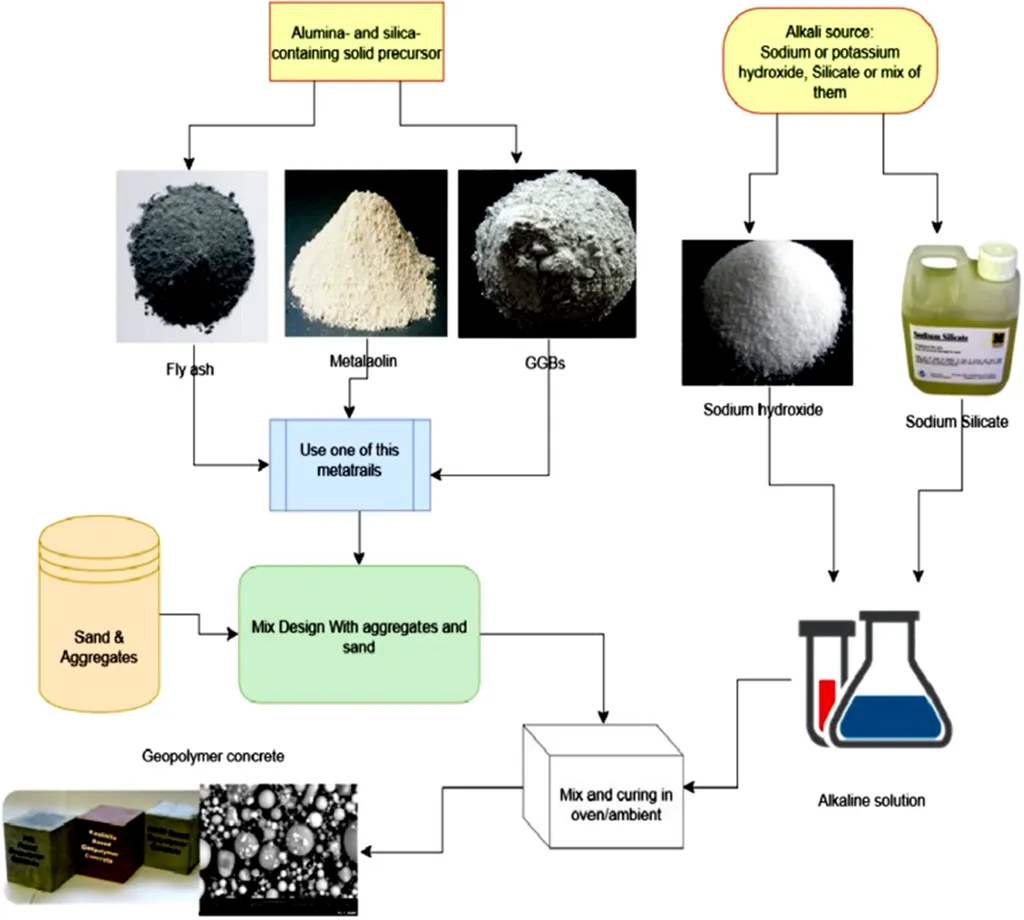

The study proposes a sustainable alternative to traditional slag- and fly ash-based geopolymer concrete. By incorporating quarry dust materials like granite powder, basalt powder, and dolomite powder as partial substitutes for fly ash, and industry waste materials such as plastic shales, plastic pellets, and crumb rubber as partial substitutes for sand, the researchers have developed a more eco-friendly concrete mix.

One of the key findings of the study is that the compressive strength of the concrete increased by about 10% when 15% of the fly ash was replaced by either basalt or dolomite powder. This enhancement in strength not only makes the material more durable but also opens up new possibilities for its use in high-stress applications within the energy sector, such as in the construction of wind turbine foundations or nuclear power plant structures.

The research also explored the impact of different curing methods on the concrete’s performance. “We found that exposing the proposed concrete to high temperatures of 300°C for 2 hours increased its compressive strength significantly,” explains AL-Mowafy. “For the control mix, the strength increased by 20.5%, and for the mix containing 15% granite powder, it increased by 29.9%.” This fire resistance property is particularly valuable for the energy sector, where materials often need to withstand extreme temperatures.

However, the study also noted that all mixes lost strength when exposed to 600°C for 2 hours, indicating a limit to the material’s heat resistance. This finding underscores the importance of further research to optimize the material’s performance under extreme conditions.

Microstructural analyses revealed that the HGC mixes had a thick and even structure, supporting their relatively high strength. This structural integrity is crucial for applications in the energy sector, where materials must withstand significant mechanical stresses and environmental conditions.

The potential commercial impacts of this research are substantial. By utilizing industrial waste and quarry dust, the HGC reduces the need for traditional raw materials, lowering production costs and environmental impact. This aligns with global sustainability goals and meets contemporary building demands, making it an attractive option for construction projects in the energy sector.

As the world moves towards more sustainable and efficient construction practices, the development of hybrid geopolymer concrete represents a significant step forward. This innovative material not only offers improved performance characteristics but also contributes to the reduction of industrial waste and the conservation of natural resources. The research led by AL-Mowafy and his team at Mansoura University is paving the way for a more sustainable future in construction and energy, demonstrating the potential of HGC as a revolutionary concrete type that meets the demands of modern infrastructure.