In the quest for sustainable construction materials, researchers have turned to an unlikely ally: sisal fibers. A recent study published in *Scientific Reports* (translated from Hindi as “Scientific Reports”) explores how these natural fibers can be transformed into a robust, eco-friendly alternative to traditional concrete reinforcements. The research, led by R. Abirami from the Department of Civil Engineering at Aarupadai Veedu Institute of Technology, Vinayaka Mission’s Research Foundation (DU), delves into the potential of sisal fiber-reinforced concrete (SiFRC) to enhance structural performance and resistance to degradation.

Sisal fibers, known for their affordability and high strength-to-weight ratio, have long been considered for engineering applications. However, their use in concrete has been limited by concerns about durability and resistance to environmental factors. Abirami’s research addresses these challenges head-on, demonstrating that chemically treated sisal fibers can significantly improve the mechanical properties and longevity of concrete.

The study involved treating sisal fibers with sodium carbonate (Na2CO3) and incorporating them into M30 grade concrete at varying percentages. The results were striking. “The tensile strength of the sisal fibers increased from 254 MPa to 332 MPa after treatment,” Abirami explains. “This improvement in fiber strength translated into better fiber-matrix bonding and enhanced overall concrete performance.”

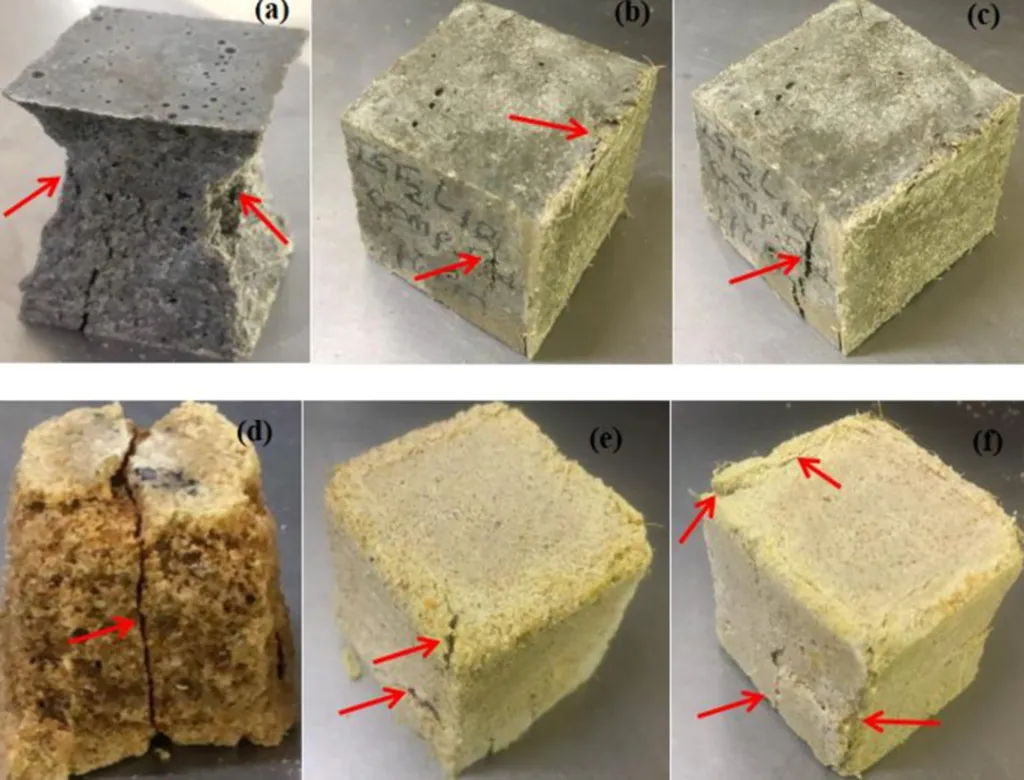

Scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDX) revealed that the treated fibers created denser interfacial transition zones and higher Ca–Si hydration products, contributing to the concrete’s durability. Durability tests further showed that SiFRC exhibited lower strength loss under chloride and sulfate exposure compared to conventional concrete. “The optimal performance was observed with 1.25% fiber addition,” Abirami notes, highlighting the potential for precise engineering of sustainable construction materials.

The implications for the construction industry are profound. As the demand for sustainable and eco-friendly materials grows, sisal fiber-reinforced concrete offers a promising alternative to synthetic fibers. “This research demonstrates that eco-friendly sisal fibers, when chemically treated, can enhance the strength and durability of concrete,” Abirami states. “It supports the use of sisal fibers as a sustainable alternative to synthetic fibers in construction.”

The findings could shape future developments in the field, encouraging further exploration of natural fibers in construction materials. As the industry moves towards more sustainable practices, the integration of sisal fibers into concrete could become a standard, offering both environmental and economic benefits. This research not only advances our understanding of natural fiber composites but also paves the way for innovative, sustainable construction solutions.