In the quest for sustainable materials, researchers have turned to an unlikely ally: castor oil. A recent study led by Herbirowo Satrio from the Research Center for Energy Materials at the National Research and Innovation Agency (BRIN) in Indonesia has demonstrated how castor oil can be used to create polyurethane (PU) foams that are not only eco-friendly but also highly versatile. Published in the EPJ Web of Conferences, which translates to the European Physical Journal Web of Conferences, this research could have significant implications for industries ranging from construction to energy.

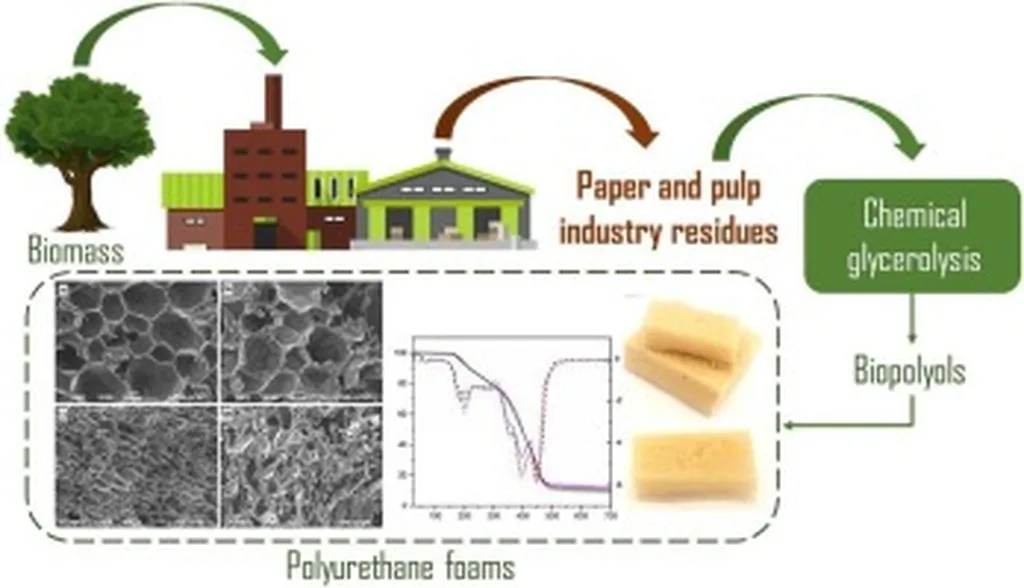

Polyurethane foams are ubiquitous, found in everything from insulation materials to packaging and even in some energy-absorbing applications. However, their production has traditionally relied on petroleum-based polyols, raising concerns about sustainability and environmental impact. Satrio’s team aimed to change that by exploring castor oil as a renewable alternative.

The researchers prepared PU foams by reacting castor-oil-based polyol with methylene diphenyl diisocyanate (MDI), using varying amounts of water as a blowing agent and silicone surfactant to stabilize the foam structure. “By adjusting these components, we were able to create foams with different properties,” Satrio explained. “Small changes in water and surfactant content led to three distinct types of foam: rigid, semi-rigid, and flexible.”

The rigid foam, formulated with 1% water and 18% surfactant, exhibited the highest strength and density. In contrast, the semi-rigid and flexible foams, created with 10% water and 2% surfactant, and 20% water and 10% surfactant respectively, were progressively softer and lighter. This versatility is crucial for commercial applications, as it allows manufacturers to tailor the foam’s properties to specific needs.

The implications for the energy sector are particularly noteworthy. In insulation materials, for instance, the ability to adjust the foam’s density and strength can lead to more efficient thermal performance, reducing energy consumption in buildings. “This research offers a practical and renewable pathway for producing PU foams with properties comparable to those made from petroleum-based materials,” Satrio noted.

The study’s findings suggest that castor-oil-based PU foams could become a viable alternative in various industries, particularly in construction and energy. As the demand for sustainable materials continues to grow, this research could pave the way for more eco-friendly and efficient solutions. “Our findings show that castor-oil-based PU foam can be tuned to meet different performance needs simply by adjusting its formulation,” Satrio added.

The research published in the EPJ Web of Conferences highlights the potential of renewable resources in creating high-performance materials. As industries strive to reduce their environmental footprint, innovations like these could play a pivotal role in shaping a more sustainable future.