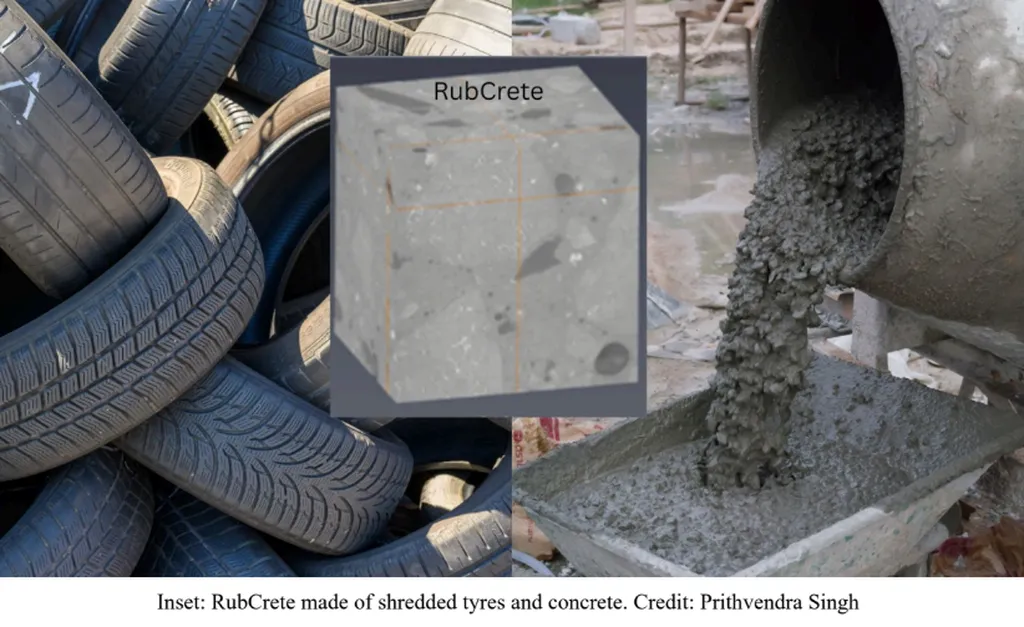

In the quest for sustainable construction materials, researchers are increasingly turning to waste materials to reduce environmental impact and improve performance. A recent study published in the European Physical Journal Web of Conferences (which translates to “European Physical Journal Web of Conferences” in English) explores the potential of using waste tire rubber as a partial replacement for fine aggregates in concrete, offering a dual benefit of reducing waste and enhancing certain material properties.

The research, led by Rathore Mansingh from the Civil Engineering Department at the Malaviya National Institute of Technology (MNIT), investigates the mechanical performance and sustainability of concrete when fine aggregates are replaced with different sizes and ratios of waste tire rubber. This approach not only addresses the environmental degradation caused by tire disposal but also reduces the dependence on natural sand, a resource that is increasingly scarce.

The study reveals that incorporating rubber into concrete leads to a decrease in compressive strength and modulus of elasticity, which can be attributed to the lower stiffness of rubber. However, this trade-off is accompanied by significant improvements in energy absorption, impact resistance, and durability. “The closed porosity achieved with rubber inclusion resists cracking under cyclic loading conditions, making it a promising material for long-term durability,” explains Mansingh.

The research also highlights the importance of optimal particle gradation and replacement percentages, typically ranging from 5% to 15%, to strike a balance between retaining strength and achieving sustainability benefits. Scanning Electron Microscopy (SEM) and chemical analysis further confirm that proper surface treatments can ensure strong bonding between rubber particles and the cementitious base.

The implications of this research are far-reaching, particularly for the energy sector, where infrastructure often requires materials that can withstand harsh conditions and cyclic loading. The enhanced durability and impact resistance of rubber-integrated concrete could lead to longer-lasting structures, reducing maintenance costs and improving overall efficiency.

As the construction industry continues to evolve, the integration of waste materials like crumb rubber into concrete aligns with the principles of the circular economy. This approach not only aids in reducing solid waste but also contributes to the development of eco-friendly infrastructure. “This study opens up new possibilities for using waste materials in construction, paving the way for a more sustainable and efficient future,” Mansingh concludes.

The findings published in the European Physical Journal Web of Conferences provide a viable path forward, demonstrating that sustainable construction materials can be both environmentally friendly and high-performing. As the industry continues to innovate, the adoption of such materials could significantly impact the energy sector, driving towards a more sustainable and resilient infrastructure.