In the quest for high-performance, low-carbon construction materials, a team of researchers led by Yan Ai from the School of Engineering & Technology at China University of Geosciences (Beijing) has made a significant breakthrough. Their study, published in the journal *Case Studies in Construction Materials* (translated from Chinese as *典型建筑材料病例研究*), focuses on enhancing the properties of cement-epoxy composite grouts using surface-modified nanosilica (SMNS). This innovation could have profound implications for the energy sector, particularly in applications requiring durable, high-strength materials.

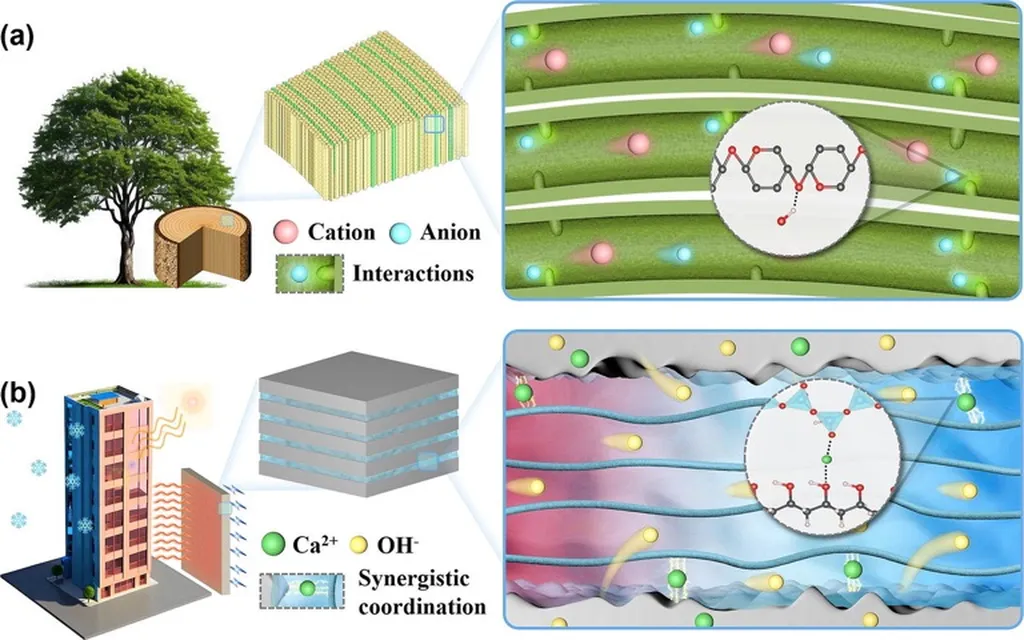

The research addresses a critical need in modern construction: the development of materials that are both robust and environmentally friendly. By incorporating SMNS into waterborne epoxy–calcium sulfoaluminate (CSA) cement grouting materials (WECG), the team has demonstrated a novel approach to improving mechanical properties and interfacial bonding. “The dual-reactive functionality of SMNS allows it to act as a nanoscale bridge between the inorganic and organic phases,” explains Yan Ai. “This enhances compatibility and significantly boosts the material’s performance.”

The study employed a multiscale approach, combining experimental data with molecular dynamics simulations. This dual methodology revealed that the Ca–O ionic coordination and chemical anchoring introduced by SMNS substantially improve interfacial bonding strength and ductility. However, the researchers also found that agglomeration at higher SMNS concentrations can detrimentally affect performance, highlighting the importance of precise dosage control.

For the energy sector, these findings are particularly relevant. Grouting materials are essential in various applications, from securing wind turbine foundations to stabilizing geothermal wells. The enhanced durability and reduced environmental impact of these composite grouts could lead to longer service life and lower maintenance costs. “This work presents a scalable strategy for designing durable grouting materials with minimal nanomaterial input,” notes Yan Ai. “It contributes to extended service life and reduced environmental impact in sustainable construction.”

The research underscores the potential for nanotechnology to revolutionize construction materials. By optimizing the use of nanomaterials, engineers can create high-performance materials that are both cost-effective and eco-friendly. As the energy sector continues to demand materials that can withstand harsh conditions and extend the lifespan of critical infrastructure, innovations like SMNS-enhanced grouts could play a pivotal role.

This study not only advances our understanding of material science but also paves the way for future developments in sustainable construction. As Yan Ai and her team continue to explore the potential of surface-modified nanosilica, the construction industry stands to benefit from more durable, efficient, and environmentally conscious materials. The findings, published in *Case Studies in Construction Materials*, offer a glimpse into a future where high-performance materials are not only achievable but also sustainable.