In a groundbreaking development that could revolutionize the construction and energy sectors, researchers have successfully transformed end-of-life mattresses into high-performance insulation materials using mycelium-based biocomposites. This innovative approach not only addresses the pressing issue of mattress waste but also offers a sustainable alternative to traditional insulation materials.

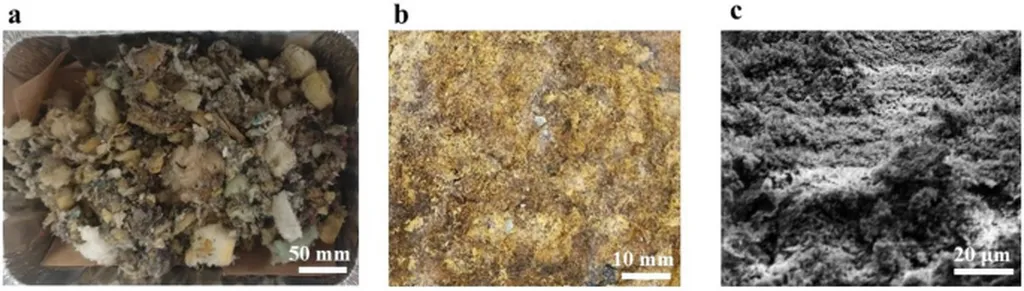

The study, led by Hong Phong Nguyen from the Department of Mechanical and Product Design Engineering at Swinburne University of Technology, focuses on the cultivation of Penicillium chrysogenum under submerged fermentation conditions. By incorporating shredded polyurethane foam from recycled mattresses into the fungal growth matrix, the team created cohesive bio-composites with exceptional thermal stability and insulation performance.

“Our research demonstrates the potential of fungal bioprocessing and biomineralization in producing high-performance, fire-resistant, and environmentally sustainable insulation materials,” said Nguyen. “This is a significant step towards a circular economy in the construction industry.”

The mycelium-mattress composite exhibited remarkable thermal stability, retaining 93±5% of its weight at 997°C and 90±5% at 1000°C. This surpasses benchmark insulation materials like glass wool, making it an attractive option for energy-efficient buildings. The composite’s thermal conductivity of 0.048±0.002 W/m.K matches or surpasses common sustainable insulators, further enhancing its commercial appeal.

The study, published in the journal *Scientific Reports* (translated to English as “Scientific Reports”), highlights the potential of this technology to shape future developments in the field. By valorizing post-consumer waste, this research offers a promising solution for reducing landfill waste and promoting sustainability in the construction industry.

As the demand for sustainable building materials continues to grow, this innovative approach could pave the way for a new generation of eco-friendly insulation materials. The commercial impacts for the energy sector are substantial, with potential applications ranging from residential buildings to industrial facilities.

“This research is a game-changer for the construction industry,” said Nguyen. “It not only provides a sustainable solution for mattress waste but also offers a high-performance insulation material that can significantly reduce energy consumption in buildings.”

The findings of this study open up new avenues for research and development in the field of bio-based composites. As the construction industry increasingly embraces sustainable practices, the adoption of mycelium-based insulation materials could become a key strategy for achieving energy efficiency and environmental sustainability.

In conclusion, this research represents a significant advancement in the quest for sustainable building materials. By harnessing the power of fungal bioprocessing and biomineralization, the team has demonstrated the potential to create high-performance, eco-friendly insulation materials that can contribute to a more sustainable future.