In the relentless pursuit of advancing space exploration, scientists are turning to an unlikely hero: fiber-reinforced concrete (FRC). As missions venture deeper into the cosmos, the structural materials that support them must withstand extreme conditions—from temperature swings that would make a desert blister to radiation that could fry electronics. Enter Liu Junyu, a researcher from the College of Civil Engineering and Transportation at Northeast Forestry University in China, who is leading the charge in exploring how FRC could revolutionize aerospace infrastructure.

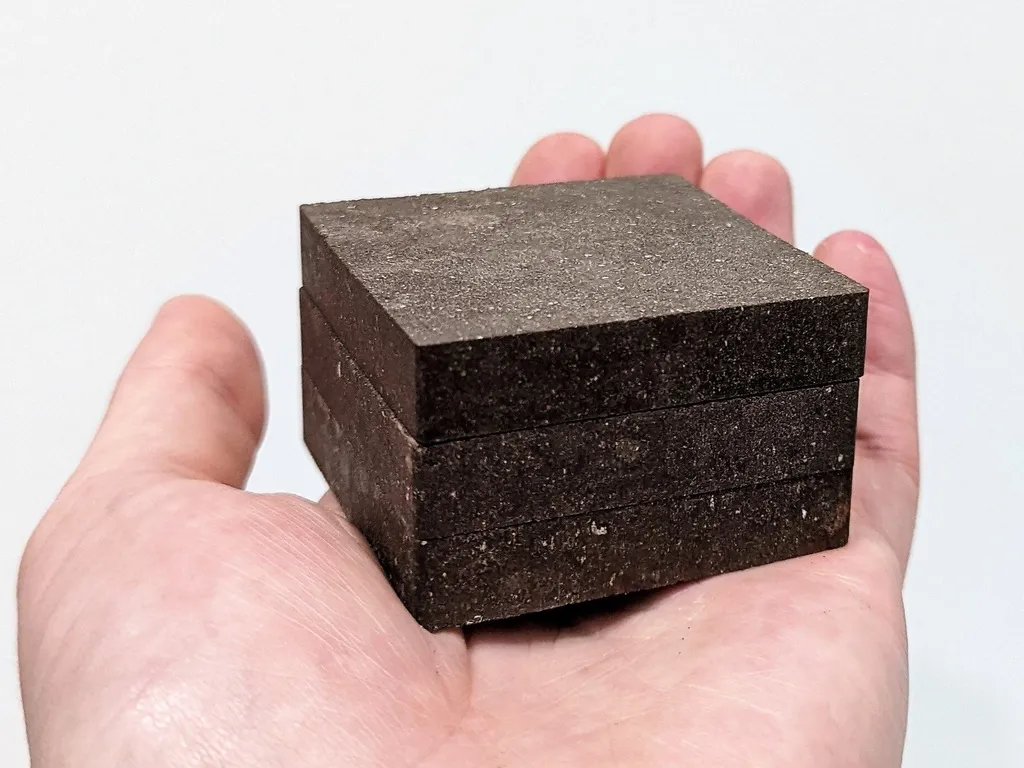

Traditional concrete, while sturdy, is notoriously brittle. It lacks the flexibility and toughness needed to endure the nonlinear challenges of space, such as cyclic loading and crack propagation. “Ordinary concrete simply can’t adapt to the extreme environments we’re encountering in space missions,” Liu explains. “That’s where fiber-reinforced concrete comes in. By embedding fibers—whether natural, synthetic, or a hybrid—we can significantly enhance its ductility, energy dissipation, and structural resilience.”

The research, published in *High Temperature Materials and Processes* (translated from Chinese as *高温材料与工艺*), delves into the mechanical properties of FRC and its nonlinear response mechanisms. The inclusion of fibers doesn’t just improve compressive strength and flexural performance; it also offers superior crack control, making it a game-changer for long-duration missions. “The fibers act like tiny reinforcements, distributing stress more evenly and preventing catastrophic failures,” Liu says. “This adaptability is crucial for structures that must endure prolonged exposure to extreme conditions.”

But the benefits don’t stop at performance. Sustainability is also a key focus. By incorporating recycled fine aggregates from construction and demolition waste, FRC reduces environmental impact while maintaining structural integrity. This dual advantage—enhanced durability and eco-friendliness—could reshape how we approach infrastructure development, not just in space but also on Earth.

The commercial implications for the energy sector are substantial. As renewable energy projects, such as offshore wind farms and solar installations, expand into harsher environments, the need for resilient materials grows. FRC could provide the durability required to withstand corrosive seawater, high winds, and temperature fluctuations, reducing maintenance costs and extending the lifespan of critical infrastructure.

Liu’s research also highlights the importance of optimizing fiber type, volume fraction, and distribution to maximize load-bearing capacity. “The key is finding the right balance,” he notes. “Too few fibers, and the material won’t gain the necessary toughness. Too many, and it becomes overly rigid, losing its adaptability.”

Looking ahead, Liu suggests that future research should focus on how FRC performs in the unique conditions of space, including high strain rates and low gravity. “We need to understand how these materials evolve over time in such environments,” he says. “This will provide the theoretical foundation for designing the next generation of aerospace infrastructure—durable, lightweight, and sustainable.”

As space missions push the boundaries of human exploration, FRC stands as a promising solution for building resilient structures that can withstand the rigors of the cosmos. And for industries on Earth, the lessons learned from this research could pave the way for more sustainable and adaptable infrastructure, ensuring a brighter future for all.