In the quest for sustainable construction materials, a recent study published in ‘Next Materials’ (translated as ‘New Materials’) has uncovered promising insights into fly ash-based geopolymer mortar (FGPM), offering a viable alternative to conventional cement. The research, led by Ishan Tank from the Department of Civil Engineering at the National Institute of Technical Teachers Training and Research (NITTTR) in Chandigarh, India, delves into the optimization of FGPM, focusing on mix proportions, curing conditions, and durability characteristics.

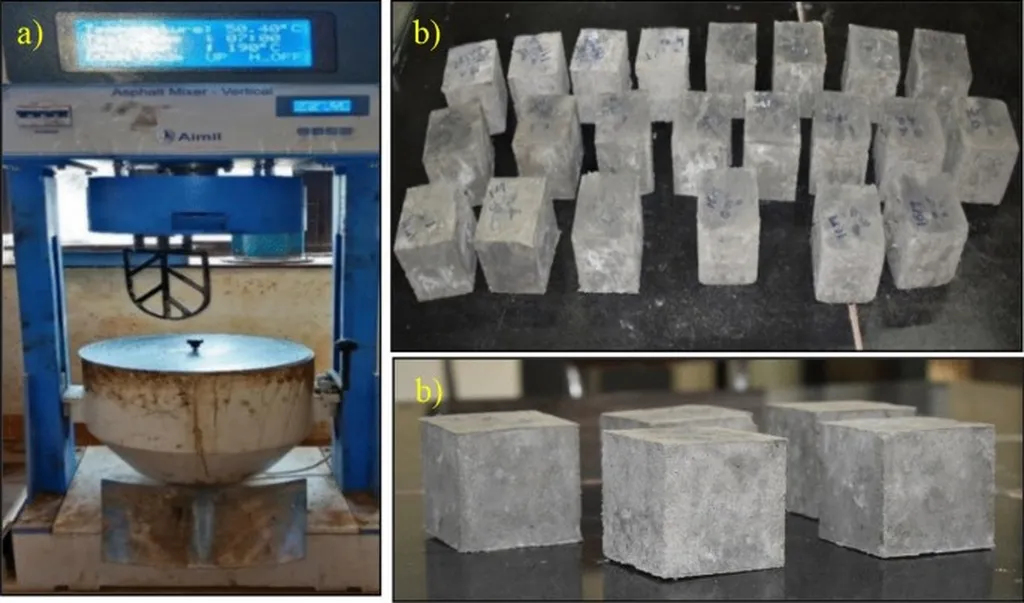

Geopolymers, known for their eco-friendly attributes, utilize industrial by-products like fly ash, significantly reducing carbon emissions compared to traditional cement. Tank’s study explores the development and optimization of FGPM, employing a fixed NaOH concentration of 14 M and a sodium silicate to sodium hydroxide ratio of 2. The research examines the impact of varying liquid-to-binder ratios and binder-to-sand ratios, with specimens subjected to heat curing at 30°C and 60°C.

The findings are compelling. The optimal mix, with a binder-to-sand ratio of 1:1 and a liquid-to-binder ratio of 0.35, cured at 60°C, achieved impressive compressive strengths of up to 35.68 N/mm² at 28 days. This represents a 25–30% improvement over specimens cured at 30°C. “The enhanced geopolymerization process at higher temperatures significantly boosts the mechanical properties of the mortar,” explains Tank.

The study also highlights the durability characteristics of the optimized FGPM. Specimens demonstrated strong resistance to NaCl, with a notable 1.07% strength gain, indicating excellent chloride resilience without the need for additives. This is particularly relevant for marine and coastal applications. However, the research also notes a vulnerability to MgSO4-driven degradation, with a strength loss of 31.1%.

The implications for the construction industry are substantial. “This approach offers valuable insights to guide the design of more efficient and robust geopolymer mortars suitable for precast structural applications,” says Tank. The optimized mix not only maximizes mechanical strength but also balances flowability, addressing key challenges in the field.

As the construction industry continues to seek sustainable and eco-friendly materials, this research provides a significant step forward. The findings could shape future developments in the field, offering a more sustainable alternative to conventional cement and contributing to the reduction of carbon emissions in the construction sector. With the detailed insights provided by Tank’s study, published in ‘Next Materials’, the industry is better equipped to embrace geopolymer mortars, paving the way for more sustainable and resilient construction practices.