In the heart of Pakistan’s bustling construction sector, a quiet revolution is underway, one that promises to reshape how waste is managed and sustainability is achieved. A groundbreaking study led by Hilal Khan from the NUST Institute of Civil Engineering (NICE) at the National University of Sciences and Technology (NUST) has shed light on the transformative potential of reverse logistics (RL) in construction and demolition (C&D) waste management. Published in the journal *Smart Construction and Sustainable Cities* (translated as “Intelligent Construction and Sustainable Cities”), the research offers compelling insights into how RL can drive sustainability and reduce waste in developing economies.

The study, which involved 36 construction projects, segmented them into three groups based on their RL maturity: none, moderate, and advanced. The results were striking. Projects with advanced RL systems achieved an average Strategic Sustainability Scorecard (S3) score 108% higher than those with no RL systems. This scorecard, developed by Khan and his team, quantifies performance across six critical dimensions: waste recovery, cost avoidance, emissions reduction, RL integration, stakeholder alignment, and regulatory compliance.

“What we found was nothing short of remarkable,” said Khan. “Advanced RL projects not only recovered over 65% of their waste materials but also avoided costs averaging PKR 4.3 million per project. This is a game-changer for the construction sector, particularly in emerging markets where resources are often scarce.”

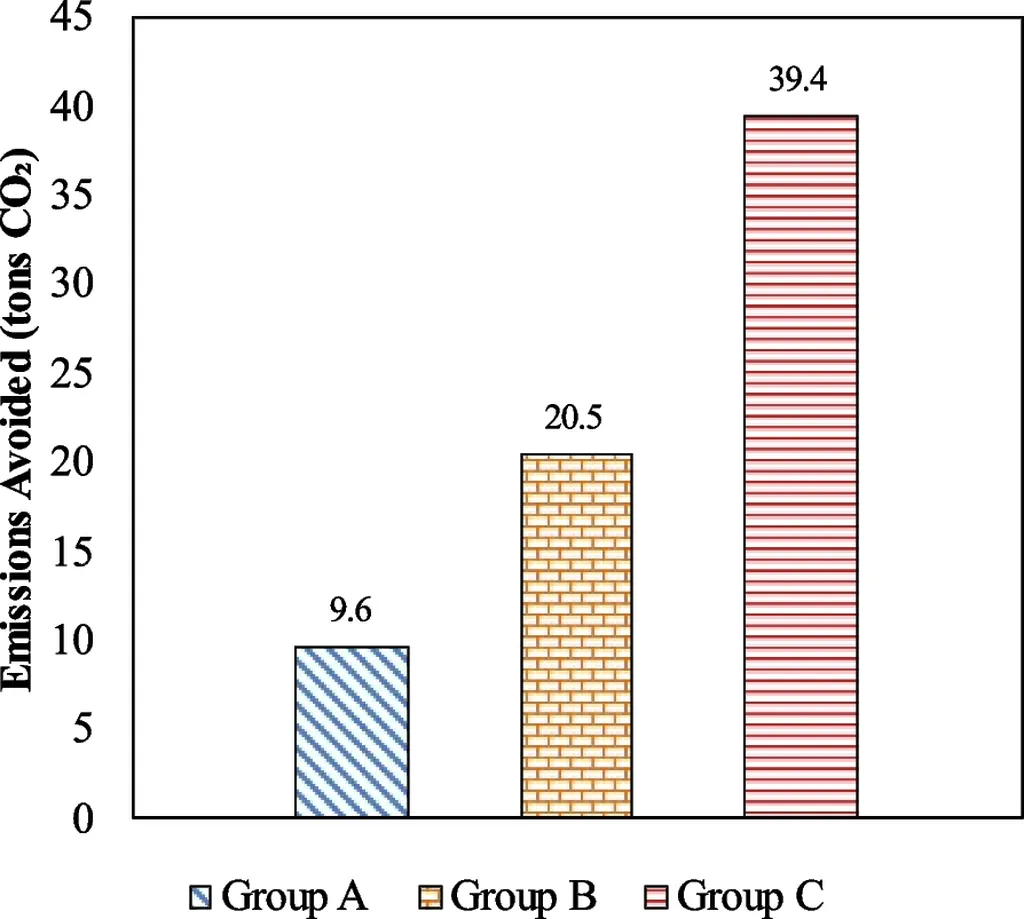

The environmental benefits were equally impressive. Emissions reductions reached up to 39.4 tons of CO₂ per project, primarily through the recovery of steel and cement. Stakeholder engagement scores showed a strong positive correlation with sustainability outcomes, highlighting the importance of institutional alignment in achieving these results.

The implications of this research are far-reaching. For the energy sector, which often intersects with construction through infrastructure projects, the adoption of RL can lead to significant cost savings and reduced environmental impact. By integrating RL into procurement strategies and regulatory frameworks, companies can drive measurable sustainability performance and contribute to the circular economy.

“This study establishes RL as a high-leverage operational and policy tool,” Khan emphasized. “It offers critical implications for procurement strategies, regulatory incentives, and circular economy integration in emerging construction markets.”

As the construction sector continues to grapple with the challenges of sustainability and waste management, the insights from this research provide a roadmap for future developments. By embracing RL, construction companies can not only reduce their environmental footprint but also unlock new opportunities for cost savings and operational efficiency. The journey towards sustainable construction has just begun, and the path forward is clearer than ever.